Abstract

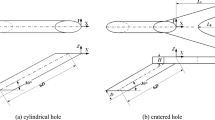

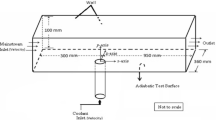

This paper presents a comparative numerical investigation on film cooling from a row of holes injected at 35° on a flat plate with three film cooling configurations, including cylindrical hole, 15° forward diffused shaped hole, and new crescent hole. All simulations are conducted at blowing ratio of 0.6 and 1.25, length-to-diameter ratio of four and pitch-to-diameter ratio of three. Computational solutions of the steady, Reynolds averaged Navier–Stokes equations are obtained using a finite volume method. Previous successful application of a two-layer turbulence model to cylindrical hole is extended to predict film cooling for the different hole geometries. It has been found that the film cooling effectiveness of cylindrical holes obviously declined along with increasing the blowing ratio. While the forward diffused shaped hole presents a marked improvement, with a higher effectiveness at the lateral area between adjacent holes. By comparison, the crescent hole exhibits the highest film cooling effectiveness among the three configurations both in spanwise and streamwise especially downstream of the intersection of the two holes. Also, the crescent hole can restrain the vortex intensity, and then enhance the film cooling effectiveness.

Similar content being viewed by others

Abbreviations

- D :

-

Diameter of film hole

- k :

-

Turbulent kinetic energy

- L/D :

-

Length-to-diameter ratio of film hole

- M :

-

Blowing ratio; M = ρ c U c /ρ ∞ U ∞

- P/D :

-

Pitch-to-diameter ratio of film hole

- Re :

-

Reynolds number

- T :

-

Local fluid temperature

- Tu:

-

Turbulence intensity

- u * :

-

Friction velocity; \( u_{ * } = \sqrt {{{\tau_{w} } \mathord{\left/ {\vphantom {{\tau_{w} } \rho }} \right. \kern-\nulldelimiterspace} \rho }} \)

- X :

-

Coordinate in the streamwise direction

- Y :

-

Coordinate normal to the test surface

- Z :

-

Coordinate in the lateral direction

- y + :

-

The normalized distance; y + = yu */v

- η :

-

Adiabatic film effectiveness; η = (T − T ∞)/(T c − T ∞)

- ε :

-

Dissipation rate of turbulence kinetic energy

- ρ :

-

Density of the fluid

- τ w :

-

Wall shear stress

- c:

-

Coolant

- w:

-

Wall

- ∞:

-

Free stream

References

Azzi A, Jubran BA (2007) Numerical modeling of film cooling from converging slot-hole. Heat Mass Transf 43(4):381–388

Bunker RS (2005) A review of shaped hole turbine film-cooling technology. Heat Transf 127(4):441–453

Gritsch M, Schulz A, Wittig S (1998) Heat transfer coefficient measurements of film cooling holes with expanded slots. ASME Paper 98-GT-28

Hyams DG, Leylek JH (2000) A detailed analysis of film cooling physics: part III—streamwise injection with shaped holes. J Turbomach 122(1):122–132

Baheri S, Alavi Tabrizi SP, Jubran BA (2008) Film cooling effectiveness from trenched shaped and compound holes. Heat Mass Transf 44(8):989–998

Sargison JE, Guo SM, Oldfield ML, Lock GD, Rawlinson AJ (2002) A converging slot-hole film-cooling geometry—part 1: low-speed flat-plate heat transfer and loss. J Turbomach 124(3):453–460

Sargison JE, Guo SM, Oldfield ML, Lock GD, Rawlinson AJ (2002) A converging slot-hole film-cooling geometry—part 2: transonic nozzle guide vane heat transfer and loss. J Turbomach 124(3):461–471

Bell CM, Hamakawa H, Ligrani PM (2000) Film cooling from shaped holes. J Heat Transf 122(2):224–232

Yu Y, Yen CH, Tip Shih, Chyu MK, Gogineni S (2002) Film cooling and heat transfer coefficient distributions around diffusion shaped holes. J Heat Transf 124(5):820–827

Lu Y, Ellad S (2007) Understanding the effect of trenching on film cooling. HT-2007-32598, Proceedings of the 2007 ASME–JSME thermal engineering summer heat transfer conference, July 2007, Vancouver

Gao Z, Narzary DP, Han J (2007) Film cooling on a gas turbine blade pressure side or suction side with compound angle shaped holes. HT-2007–32098, Proceedings of the 2007 ASME–JSME thermal engineering summer heat transfer conference, July, 2007. Vancouver, BC

Azzi A, Jubran BA (2004) Influence of leading-edge lateral injection angles on the film cooling effectiveness of a gas turbine blade. Heat Mass Transf 40(6-7):501–508

Azzi A, Lakehal D (2002) Perspectives in modeling film-cooling of turbine blades by transcending conventional two-equation turbulence models. J Turbomach 124(3):472–484

LU YP (2007) Effect of hole configurations on film cooling from cylindrical inclined holes for the application to gas turbine blades. PhD dissertation, Louisiana State University

Schmidt DL, Sen B, Bogard DG (1996) Film cooling with compound angle holes: adiabatic effectiveness. J Turbomach 118(4):807–813

Kim YJ, Kim SM (2004) Influence of shaped injection holes on turbine blade leading edge film cooling. Int J Heat Mass Transf 47(2):245–256

Gritsch M, Schulz A, Wittig S (1998) A diabatic wall effectiveness measurements of film-cooling holes with expanded exits. J Turbomach 120(3):549–556

Shuye T, Han JC, Poinsatte PE (2001) Effect of film-hole shape on turbine blade film cooling performance. J Thermophys Heat Transf 15(3):257–265

Acknowledgments

The work was supported by the Ph.D. foundation of Qingdao University of Science and Technology (No. 0022442).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dai, P., Lin, F. Numerical study on film cooling effectiveness from shaped and crescent holes. Heat Mass Transfer 47, 147–154 (2011). https://doi.org/10.1007/s00231-010-0692-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-010-0692-5