Abstract

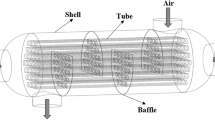

This study concerns a new type of heat exchangers, which is that of shell-and-double concentric-tube heat exchangers. These heat exchangers can be used in many specific applications such as air conditioning, waste heat recovery, chemical processing, pharmaceutical industries, power production, transport, distillation, food processing, cryogenics, etc. The case studies include both design calculations and performance calculations. It is demonstrated that the relative diameter sizes of the two tubes with respect to each other are the most important parameters that influence the heat exchanger size.

Similar content being viewed by others

Abbreviations

- b :

-

Baffle pitch, m

- C :

-

Heat capacity flow rate, W/K

- C p :

-

Specific heat, J/(kg K)

- D :

-

Diameter, m

- d :

-

Inner tube diameter, m

- F :

-

Corrective factor

- G :

-

Mass velocity, kg/(m2 s)

- h :

-

Convective heat transfer coefficient, W/(m2 K)

- K :

-

Overall heat transfer coefficient, W/(m2 K)

- L :

-

Length of tube, m

- M :

-

Mass, kg

- m :

-

Mass flow rate, kg/s

- N c :

-

Number of baffles

- N t :

-

Total number of tubes

- N td :

-

Number of tubes on the shell diameter

- Ntp :

-

Number of tubes by pass

- p :

-

Tube pitch, m

- P T :

-

Friction power expenditure, W

- Δp :

-

Pressure drop, Pa

- Q :

-

Mass flow rate, kg/h

- S :

-

Exchange surface, m2

- S p :

-

Flow cross sectional area, m2

- Τ :

-

Temperature, °C

- ΔΤ ML :

-

Log-mean temperature difference, °C

- v :

-

Fluid velocity, m/s

- Z :

-

Heat capacity flow rate ratio

- δ:

-

Thickness, m

- η:

-

Heat exchanger effectiveness

- κ:

-

Factor taking account of the ratio of the internal and external diameters in the cases of the annular tubes

- λ:

-

Thermal conductivity, W/(m K)

- μ:

-

Dynamic viscosity, Pa s

- π:

-

3.14l59 rad

- ρ:

-

Density, kg/m3

- Φ:

-

Heat flux, W

- υ:

-

Kinematic viscosity, m2/s

- Ω:

-

Darcy coefficient

- Nu :

-

Nusselt number: Nu = hd h /λ

- Pr :

-

Prandtl number: Pr = μC p /λ

- Re :

-

Reynolds number: Re = vd h /υ

- 1:

-

Industrial oil (shell side), outer

- 2:

-

Water, inner

- 3:

-

Industrial oil (inner tube)

- c:

-

Shell

- h:

-

Hydraulic

- i:

-

Inlet

- io:

-

Industrial oil

- o:

-

Outlet

- st:

-

Shell-and-tube heat exchanger

- sdct:

-

Shell-and-double concentric-tube heat exchanger

- t:

-

Wall

References

Kern DQ (1984) Process heat transfer. McGraw-Hill, New York

Pierre B (1983) Dimensionnement des échangeurs de chaleur. Revue Générale Thermique 587–615

Bougriou C (1991) Etude du transfert de chaleur par condensation d’air humide sur des tubes à ailettes. PhD thesis, INSA de Lyon ISAL87

Gnielinski V (1976) New equations for heat transfer in turbulent pipe and channel flow. Int Chem Eng 16:359–368

Gnielinski V, Zukauskas A, Skrinska A (1983) Banks of plains and finned tubes, single phase convective heat transfer. In: Heat exchanger design handbook, vol 2, 2.5.3.1–2.5.3.16

Gnielinski V (1978) Gleichungen zur Berechnung des warmeübergangs in querdurchstromten einzelnen rohrreihen und rohrbudeln, Forsch. Ingenieurwes 44:15–25

Zukauskas A, Ambrazyavizius AB (1961) Heat transfer of plate in a liquid flow. Int J Heat Mass Transf 3:305–309

Bouvenot A (1981) Transfert de chaleur. Masson, Paris

Sacadura JF (1980) Initiation aux transferts thermiques. Techniques et Documentation, France

Frass AP, Ozisik MN (1965) Heat exchangers design. Wiley, New York

Afgan V, Schlunder EU (1974) Heat exchangers; design and theory. McGraw-Hill, New York

Bougriou C, Baadache K (2008) Shell-and-double concentric-tube heat exchangers. Patent PCT, DZ2008/000002

Bougriou C, Bessaïh R, Le Gall R, Solecki JC (2004) Measurement of the temperature distribution on a circular plane fin by infrared thermography technique. Appl Therm Eng 24:813–825

Bougriou C, Bessaïh R (2005) Determination of apparent heat transfer coefficient by condensation in an industrial finned-tube heat exchanger: prediction. Appl Therm Eng 25(11–12):1579–1587

Bougriou C, Bessaïh R, Bontemps A (2005) Experimental and computational performances of heat exchangers functioning in wet regime by using the film method. Int Commun Heat Mass Transf 32:1135–1142

Bougriou C, Bessaïh R, Bontemps A (2005) Experimental study of performances of industrial heat exchangers functioning in wet regime. Int J Heat Exch 6:179–202

Bougriou C, Bessaïh R (2007) Prediction and measurement of apparent heat transfer coefficient by condensation in finned-tube heat exchangers. Heat Transf Eng 28:940–953

Bougriou C (2002) Etude du récupérateur de chaleur croisé à tubes à ailettes. Revue des Energies Renouvelables 5:59–73

Bougriou C (1999) Etude du récupérateur de chaleur croisé à tubes lisses. Revue des Energies Renouvelables 2:109–122

Bougriou C (1998) Calcul et technologies des échangeurs. Department of Mechanics, University of Batna, Batna

Baadache K (2005) Etude numérique d’un échangeur de chaleur à triple tube concentrique en régime permanent (Co-courant et Contre-courant). Department of Mechanics, University of Batna, Batna

Sekulic DP, Herman CV (1987) Transient temperature fields in a three fluid heat exchanger. In: Proceedings of the 17th international congress of refrigeration, Vienna, B, pp 833–837

Űnal A (1998) Theoretical analysis of triple concentric-tube heat exchanger—Part I Mathematical modeling. Int Commun Heat Mass Transf 25:949–958

Űnal A (2001) Theoretical analysis of triple concentric tube heat exchanger—Part II Case studies. Int Commun Heat Mass Transf 28:243–256

García-Valladares O (2004) Numerical simulation of triple concentric-tube heat exchangers. Centro de Investigación en Energía (CIE), Universidad Nacional Autónoma de México (UNAM), Privada Xochicalco S/N, Temixco, 62580 Morelos, Mexico, pp 980–991

Zuritz C (1990) On the design of triple concentric-tube heat exchangers. J Food Process Eng 12:113–130

Ünal A (2003) Effectiveness-NTU relations for triple concentric-tube heat exchangers. Int Commun Heat Mass Transf 30:261–272

Bontemps A, Garrigue A, Goubier C, Huetz J, Marvillet C, Mercier P, Vidil R (1998) Echangeur de chaleur—dimensionnement thermique. Techniques de l’ingénieur, traité Génie énergétique. B, pp 21–16

Idelcik IE (1986) Handbook of hydraulic resistance. Eyrolles, Paris

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bougriou, C., Baadache, K. Shell-and-double concentric-tube heat exchangers. Heat Mass Transfer 46, 315–322 (2010). https://doi.org/10.1007/s00231-010-0572-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-010-0572-z