Abstract

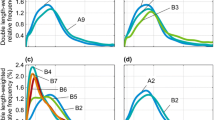

The properties of medium-density fiberboard (MDF) panels as affected by wood fiber characteristics were investigated. Wood chips from three softwood and one hardwood species were refined under the same refining conditions to make four different types of fibers. The resulting fibers were characterized by fiber size distribution, bulk density, pH value, and buffering capacity. Using the same resin system and hot-pressing parameters, MDF panels were produced and evaluated for internal bonding (IB), modulus of rupture (MOR), modulus of elasticity (MOE), thickness swelling, and linear expansion. The pH values and alkaline buffering capacities of raw materials were reduced considerably after refining. IB was strongly related to the pH value of fibers. The mechanical properties increased with alkaline buffering capacity. IB, MOR, and MOE increased with the bulk density of fibers. Increased proportions of coarse fibers had negative effects on the panel mechanical properties.

Similar content being viewed by others

References

Albritton RO, Short PH (1979) Effects of extractives from pressure-refined hardwood fiber on the gel time of urea-formaldehyde resin. For Prod J 29(2):40–41

American National Standards Institute (ANSI) Medium density fibreboard (MDF) for interior application. ANSI A208.2-2002. Composite Panel Association, Gaithersburg

American Society of Testing and Materials (ASTM) (2001) Evaluating properties of wood-based fiber and particle panel materials. ASTM D 1037-99. ASTM, Philadelphia

Dunky M (1998) Urea-formaldehyde (UF) adhesive resins for wood. Int J Adhes 18:95–107

Guo AL, Zhang HS, Feng LQ, Gao XX, Zhang GL (1998) pH value and buffering capacity of 6 shrub species and relevant effect on curing time of UF resin. Chine Wood Indu 12(5):18–20

Johns WE, Niazi KA (1980) Effect of pH and buffering capacity of wood on the gelation time of urea-formaldehyde resin. Wood Fiber Sci 12(4):255–263

Maloney TM (1993) Modern particleboard and dry-process fiberboard manufacturing. Miller Freeman, San Francisco

McMillin CW (1968) Fiberboards from loblolly pine refiner ground-wood: effect of gross wood characteristics and board density. For Prod J 18(8):51–59

McMillin CW (1969) Fiberboards from loblolly pine refiner ground-wood: aspects of fiber morphology. For Prod J 19(7):56–61

Myers GC (1983) Relationship of fiber preparation and characteristics to performance of medium-density hardboards. For Prod J 33(10):43–51

Nelson ND (1973) Eddects of wood and pulp properties on medium-density dry-formed hardboard. For Prod J 23(9):72–80

Park BD, Kim YS, Riedl B (2001) Effect of wood-fiber characteristics on medium density fiberboard (MDF) performance. J Korean Wood Sci Technol 29(3):27–35

Peng HY, Li J (1983) Effect of pH and the buffering capacity of economic wood species growing in northeast on the gel time of urea-formaldehyde resin. J North East For Ins China 11(4):100–105

Peter JJ, Bender DA, Wolcott MP, Johnson JD (2002) Selected properties of hybrid poplar clear wood and composite panels. For Prod J 52(5):45–54

Pizzi A, Panamgama LA (1995) Diffusion hindrance vs. wood-induced catalytic activation of MUF adhesive polycondensation. J Appl Polym Sci 58(1):109–115

Pizzi A, Mtsweni B, Parsons WJ (1994) Wood-induced catalystic activation of PF adhesives autopolymerization vs. PF/wood covalent bonding. J Appl Polym Sci 52(13):1847–1856

Roffael E, Dix B, Schneider T (2001) Thermomechanical (TMP) and chemothermomechanical pulps (CTMP) for medium density fibreboards (MDF). Holzforschung 55:214–218

Shi JL, Zhang SY, Riedl B (2005) Effect of juvenile wood on strength properties and dimensional stability of black spruce medium density fiberboard panels. Holzforschung 59:1–9

Slay JR, Short PH, Wright DC (1980) Catalytic effect of extractives from pressure-refined hardwood fiber on the gel time of urea-formaldehyde resin. For Prod J 30(3):22–23

Suchsland O, Woodson GE (1991) Fiberboard manufacturing practices in United States. Forest Products Research Society

Van Niekerk J, Pizzi A (1994) Characteristic industrial technology for exterior Eucalyptus particleboard. Holz Roh-Werkst 52:109–112

Xing C, Riedl B, Cloutier A (2004a) Measurement of urea-formaldehyde resin distribution as a function of MDF fiber size by laser scanning microscopy. Wood Sci Technol 37(6):495–507

Xing C, Zhang SY, Deng J (2004b) Effect of wood acidity and catalyst on UF resin gel time. Holzforschung 58:408–412

Xing C, Deng J, Zhang SY, Riedl B, Cloutier A (2005) DSC characterization of UF resin curing behavior as affected by less desirable wood material and catalyst content. J Appl Polym Sci 98(5):2027–2032

Xing C, Riedl B, Cloutier A, Deng J, Zhang SY (2006) UF resin efficiency of MDF as affected by resin content loss, coverage level and pre-cure. Holz Roh-Werkst DOI 10.1007/s00107-006-0101-4

Zanetti M, Pizzi A (2003) Upgrading of MUF resins by buffering additives-part 2: hexamine sulphate mechanisms and alternate buffers. J Appl Polym Sci 90(1):215–226

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xing, C., Zhang, S.Y., Deng, J. et al. Medium-density fiberboard performance as affected by wood fiber acidity, bulk density, and size distribution. Wood Sci Technol 40, 637–646 (2006). https://doi.org/10.1007/s00226-006-0076-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-006-0076-7