Abstract

The growing awareness of the consumers on the advantages of a proper nutrition is deeply modifying their demands. Hence, the exploitation of innovative ingredients to enrich the nutritional values of staple foods is continuously explored by research institutions and food industries. This paper represents a feasibility study on the use of nonconventional ingredients, including house cricket (Acheta domesticus) powder and buckwheat (Fagopyrum esculentum) flour, for the production of novel flatbread formulations. Experimental flatbread prototypes were evaluated by analyzing microbiological, physico-chemical, textural, colorimetric, and volatile parameters. Microbiological viable counts revealed low levels of bacterial spores in the formulations comprising cricket powder. Water activity results showed adequate values, inhibiting the growth of spoilage and pathogenic bacteria, and preventing the germination of bacterial spores. The addition of cricket powder, influenced textural properties of flatbread samples, characterized by lower hardness values respect to those not containing insects seems likely due to a high content of dietary fiber (chitin from insects). As for the color analysis, flatbread samples added with cricket powder evidenced darker tones respect to those not containing insects, thus resulting visibly comparable with whole grain products. Worthy to mention that the addition of buckwheat flours did not cause hardness reduction or color variation of experimental prototypes. The volatile component analysis highlighted numerous compounds associated with enzymatic activities and nonconventional ingredients. Overall, the results collected demonstrated that cricket powder and buckwheat flour possess a great potential to produce innovative flatbreads.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the recent years, consumers’ knowledge about proper nutritional intake is significantly influencing their food choice behavior. Furthermore, the willingness to accept innovative foods is directly associated with the information on their health beneficial effects [1].

In such a context, the exploitation of innovative ingredients to enrich the nutritional values of staple foods is continuously explored by research institutions and food industries [2,3,4]. Among the most emerging innovative ingredients, edible insects are considered as a source of high-value proteins constituted by both essential and nonessential amino acids that may represent a valid alternative to conventional protein sources [5]; moreover, the insects contain notable amounts of polyunsaturated fatty acids, essential minerals, and vitamins [5]. In addition, edible insects are source of a wide range of bioactive compounds as antimicrobial peptides (e.g., cecropin, mellitin, attacin, etc.) to be potentially applied in the nutraceutical sector [5]. Entomophagy represents a common practice in Asian countries as Thailand, Japan, Laos, Borneo, and India, whereas it is gradually emerging in North America and Europe [5]. In the EU, the human consumption of edible insects is governed by Regulation (EU) No. 2015/2283 [6] on novel foods. In more detail, the commercialization of insect-based products must be authorized by the European Commission (EC) following the risk assessment for food safety performed by the European Food Safety Authority (EFSA) [7]. So far, frozen and dried formulations from whole yellow mealworm (Tenebrio molitor), lesser mealworm (Alphitobius diaperinus), migratory locust (Locusta migratoria), and whole house crickets (Acheta domesticus) were officially authorized at EU level, whereas further authorizations are soon expected [8,9,10,11,12,13]. The interest of the scientific community on the exploitation of edible insects in the production of innovative foods is constantly increasing to obtain nutritious, healthy, safe, and tasty products that may potentially expand the market offer [7]. It is noteworthy that entomophagy practice is encouraged in nonregular consumers by the formulation of conventional products added with processed edible insects. Consequently, the edible insect formulations not only include whole insect products, but also processed insect powders, insect-based bars and shakes, and insect-based baked products [5].

Buckwheat belongs to the family of Polygonaceae and is commercially collocated among pseudo-cereals for its nutritional characteristic and food use [14]. The buckwheat grains are considered extremely nutritious because of the presence of polyphenols, especially flavonoids, dietary fibers, and other nutraceutical components, and high-quality proteins, with one of the most valuable amino acid scores among plant-based protein compositions. Furthermore, the notable concentrations of resistant starch in buckwheat grains are well known. The continued consumption of resistant starch confers remarkable health benefits, including regulation of blood glucose and cholesterol levels, and maintenance of intestinal balance [15]. Buckwheat is mainly produced in Eastern European and Central Asiatic countries, whereas its demand is steadily growing in the United States, Canada, and Europe. Usually, buckwheat grains are dehulled and used for breakfast cereals or processed for the preparation of bakery products, such as biscuits and bread [14].

Bread represents a staple food all over the world, especially in European countries, and it has already been used as model food to be enriched in nutritional compounds. Commonly, bread is prepared by mixing wheat flour, water, and a leavening agent, with or without the addition of salt and other ingredients, including malt, oils, additives, etc. According to ingredient choice, preparation method, and shape and size, a plenty of bread varieties (flatbread, loaf bread, crackers, sticks, etc.) were developed to meet the needs of consumers. Among these, flatbread is one of the most ancient bread preparations made by baking a flattened dough. As recently reviewed by Boukid [3], flatbreads are considered as versatile products to be used as vehicles of nonconventional and health-promoting ingredients to enhance the nutritional properties and, at the same time, maintain acceptable sensory properties of the end-products. As for the leavening agent used for bread production, the most common choices comprise chemicals (e.g., sodium bicarbonate), baker’s yeast, namely Saccharomyces cerevisiae biomass, and sourdough. This latter leavening agent consists of a dough generally obtained from wheat flour and water spontaneously fermented by lactic acid bacteria and yeasts naturally occurring in the raw materials, and continuously propagated by back-slopping [4, 16, 17]. Notably, the addition of sourdough confers unique rheological and sensory features to the end-product [18]. Furthermore, different nutritional properties associated with sourdough were documented, including: a decrease of bread glycemic index, an increase in micronutrients absorption (e.g., phytase activity), improvement of the dietary fiber complex’s properties, and release of bioactive compounds (e.g., γ-amino butyric acid, lunasin, alkylresorcinol, etc.) [19, 20].

As far as the authors are aware, the use of cricket powder, buckwheat flour, and buckwheat-based sourdough to produce flatbread has never been explored before. Hence, in the present paper, the results of a feasibility study on the use of the abovementioned nonconventional ingredients for the production of novel flatbread formulations were discussed. In more detail, the objectives of the experimental plan include: i) evaluation of the use of cricket powder in wheat- or buckwheat-based flatbread production; ii) among buckwheat sources, evaluation of the use of different types of flours obtained from Italian or Polish crops; iii) evaluation of the use of different leavening agents, namely baker’s yeast and sourdoughs obtained from either wheat or buckwheat flours. To define the optimal flatbread recipe, experimental flatbreads were produced using different blends of insect powder, buckwheat flour, baker’s yeast, and sourdough. The evaluation of the experimental flatbreads was carried out by analyzing their microbiological profile, volatile components, textural and colorimetric traits, and physico-chemical parameters.

Materials and methods

Raw materials

Soft wheat flour, durum wheat flour, chickpea flour, oat flour, and barley malt were purchased from a local organic produce market situated in Wrocław (Poland). The Polish buckwheat grains were obtained in Melvit, Warsaw, Poland. The Italian buckwheat grains were obtained from the consortium of organic agriculture Terra Bio (Urbino, Italy). House crickets (Acheta domesticus) were purchased from the biotechnology company Nutrinsect (Montecassiano, Italy) and were freeze-dried by using a SP VirTis Freeze Dryer (Scientific Products, Pennsylvania, USA). Both buckwheat grains and house crickets were shipped to Wrocław (Poland) in vacuum-sealed plastic bags by international express transport under controlled temperature conditions. Later, buckwheat grains and house crickets were grounded under aseptic conditions by using a stone mill (Fidibus 21, KoMo, Hopfgarten, Austria) and a high-speed knife mill FW135 (Chemland, Gdansk, Poland), respectively. All the raw materials were stored at 4 °C until use.

Production of sourdoughs

Three different types of sourdough made with i) wheat flour, ii) Polish buckwheat flour or iii) Italian buckwheat flour were produced according to the methods described by Yu et al. [21], and Moroni et al. [22] with some modifications. In more detail, each flour was mixed with sterile tap water to reach a final dough yield of 200. The resulting doughs were incubated at 30 °C and propagated by back-slopping every 24 h for 10 days. All propagation steps were performed by adding 300 g of fermented dough to 300 g of respective flour and 300 g of sterile tap water under aseptic conditions. pH of each sourdough was monitored by using a pH meter (EMETRON CP-411, Zabrze, Poland) equipped with an electrode (HYDROMET, Gliwice, Poland) to verify their effective maturation (reduction of pH). No starter cultures were added during the fermentation processes.

High-throughput sequencing and bioinformatic analysis of sourdoughs

The bacterial microbiota of sourdough samples was analyzed by amplifying the V3−V4 hypervariable region of the 16S rRNA gene with the primers and procedure described by Klindworth et al. [23]. The PCR amplicons were purified following the Illumina metagenomic pipeline (Illumina, San Diego, California, USA) and sequenced with a MiSeq platform (Illumina) generating 250 bp paired-end reads. Paired-end reads were imported in QIIME2 software for chimeric join and quality filtering [24,25,26,27]. For bacterial taxonomic assignment, the Amplicon Sequence Variants (ASVs) generated through DADA2 were compared with Greengenes 16S rRNA gene database. ASVs taxonomy assignment was then confirmed by manual BLAST. The ASVs table obtained with QIIME2 was rarefied at the lowest number of sequences and, when displayed, the higher taxonomy resolution was reached. When the taxonomy assignment was not able to reach species level, the genus or family name was displayed.

Composition of doughs and bread making

The dough formulations of the present study are listed in Table 1. In more detail, the following experimental thesis were explored: (i) the production of flatbread doughs either with baker’s yeast or wheat sourdough (encoded with WB and WS, respectively); (ii) the production of flatbread doughs by adding cricket powder either with baker’s yeast or wheat sourdough (encoded with IB and IS, respectively); (iii) the production of flatbread doughs by adding cricket powder and buckwheat flour obtained from Italian crops either with baker’s yeast or buckwheat sourdough (encoded with ITAB and ITAS, respectively); iv) the production of flatbread doughs by adding cricket powder and buckwheat flour obtained from Polish crops either with baker’s yeast or buckwheat sourdough (encoded with POLB and POLS, respectively). The dough yield of each flatbread formulation was kept constant at 150. As for dough formulations incorporating sourdough, the ratio of flours and sourdough was 3:1 and water content was reduced to avoid modifications on the dough properties, as already proposed by Yu et al. [21]. Cricket powder was added as a partial replacement of soft and durum wheat flour to obtain a final rate of 20% of the total flour weight. Buckwheat flour was added as a replacement of chickpea and oat flours to obtain a final rate of 18% of the total flour weight.

Initially, all ingredients were mixed for 10 min in a planetary mixer FM-201 (Łucznik, Wrocław, Poland) and the resulting doughs were left leavening at 25 °C for 1 h. Afterwards, the doughs were shaped to obtain thin squares of 10 cm of length and width, and 2 mm of height; hence, a roller docker was used to pierce the doughs that were finally sprinkled with salt. The flatbread doughs were oven cooked in steam-convection oven (HENDI 227077, Rhenen, The Netherlands) at 240 °C for 5 min. Experimental flatbreads (Fig. 1) were codified as FWB (made from WB), FIB (made from IB), FITAB (made from ITAB), FPOLB (made from POLB), FWS (made from WS), FIS (made from IS), FITAS (made from ITAS), and FPOLS (made from POLS). Each baking process was carried out in duplicate and related analyses were performed after at least one hour of cooling at room temperature.

Experimental flatbread samples. FWB, flatbread samples made with baker’s yeast, FIB, flatbread samples made with baker’s yeast and cricket powder, FITAB, flatbread samples made with baker’s yeast, cricket powder, and Italian buckwheat flour, FPOLB, flatbread samples made with baker’s yeast, cricket powder, and Polish buckwheat flour, FWS, flatbread samples made with wheat sourdough, FIS, flatbread samples made with wheat sourdough and cricket powder, FITAS, flatbread samples made with Italian buckwheat sourdough, cricket powder, and Italian buckwheat flour, FPOLS, flatbread samples made with Polish buckwheat sourdough, cricket powder, and Polish buckwheat flour

Microbiological analyses

Ten g-aliquots of each raw material, sourdough, dough, and flatbread sample were suspended with 90 mL of sterile water added with 0.85% of NaCl (w v−1). The homogenization of the samples was carried out at 260 rpm for 5 min by using a Stomacher 400 Circulator apparatus (VWR International, Gdańsk, Poland). The resulting suspension were tenfold serially diluted in sterile peptone water to quantify the following microbial groups:(i) total mesophilic aerobes in Plate Count Agar (PCA) (BTL ltd, Łódź, Poland) incubated at 30 °C for 48 h; (ii) presumptive lactic acid bacteria in De Man, Rogosa and Sharp (MRS) agar (BTL ltd, Łódź, Poland) added with 250 mg of cycloheximide per L incubated at 37 °C for 48 h; (iii) eumycetes in Rose Bengal Chloramphenicol (RB) agar (BTL ltd, Łódź, Poland) incubated at 25 °C for 72 h; (iv) bacterial spores counted after a thermal treatment of the homogenates at 80 °C for 10 min followed by cooling in iced water for 5 min and plated in PCA (BTL ltd, Łódź, Poland) incubated at 30 °C for 48 h. The results of the microbial viable counts were expressed as the Log of colony forming units (cfu) per gram of sample and were reported as mean value ± standard deviation of two biological and two technical replicates.

Physico-chemical measurements

The pH value of each sourdough and dough sample was measured by using a pH meter (EMETRON CP-411) equipped with an electrode (HYDROMET) inserted at their core. The total titratable acidity (TTA) of each sourdough, dough, and flatbread sample was determined as follows: ten g-aliquots were homogenized with 90 mL of demineralized water through a Stomacher 400 Circulator apparatus (VWR International) at 260 rpm for 5 min; subsequently, the mL of NaOH 0.1 N needed to reach the pH fixed endpoint of 8.3 were measured. The water activity (aw) of each flatbread sample was measured by using an Aqualab 4TE apparatus (Meter Group, Pullman, USA). The results of the physico-chemical analyses were reported as mean value ± standard deviation of two biological and two technical replicates.

Baking loss, specific volume, and textural analysis

The baking loss of flatbread samples was obtained by weighing the doughs before their baking (wd) and the breads after their baking (wb). The weight loss percentage was calculated as follows:

The specific volume of flatbread samples was determined by applying the AACC Method 10–05.01 [28] with some modifications. In more detail, a container was filled with rapeseeds that were subsequently poured in a graduated cylinder to obtain their volume (v1). Thereafter, a flatbread sample was weighted (wf) and inserted in the same empty container and covered with rapeseeds up to the maximum capacity. The rapeseed volume was again measured (v2) and the specific volume of each flatbread sample was calculated as follows:

The hardness of flatbread samples was measured by applying the three-point bending test [29, 30]. In more detail, the Texturemeter FC200STAV50 AXIS (Axis Ltd, Gdansk, Poland) was used as follows: a flatbread sample was placed above two supports set 8 cm apart, and a loading force was exerted on the center of the product by a wedge moving downwards at a speed of 150 mm min−1. The results were expressed as the maximum force (N) required to break the sample. The data of baking loss, specific volume, and fracturability analysis were collected from five technical and two biological replicates.

Color analysis

Prior to the addition of wet components and dough formation, flour mixtures were encoded as MW (used for production of flatbread samples not containing insects), MI (used for production of flatbread samples added with cricket powder), MITA (used for production of flatbread samples added with cricket powder and buckwheat flour obtained from Italian crops), and MPOL (used for production of flatbread samples added with cricket powder and buckwheat flour obtained from Polish crops), and were analyzed for color parameters. The color of flour mixture, dough, and flatbread samples was determined according to CIELAB color space parameters using a Konica Minolta CR-310 chromameter (Ramsey, NJ, USA) connected with a Data Processor (DP-301), launched via RS232 serial port to the personal computer. In more detail, the following parameters were obtained: (i) lightness (L*) ranging from 0 (black) to 100 (white); (ii) greenness or redness (a*) with negative values corresponding to green axis and positive values corresponding to red axis; (iii) blueness or yellowness (b*) with negative values corresponding to blue axis and positive values corresponding to yellow axis; (iv) chroma (C*) expressing the purity of the color from gray to pure spectral colors; (v) hue angle (h°) extending from 0° (red), 90° (yellow), 180° (green) to 270° (blue) [31, 32]. In addition, the total color difference (ΔE) between (i) flour mixture samples added with cricket powder and flour mixture samples not containing insects, (ii) dough samples added with cricket powder made with bakers’ yeast or sourdough and dough samples not containing insects, (iii) flatbread samples added with cricket powder made with bakers’ yeast or sourdough and flatbread samples not containing insects was calculated as follows [33]:

L lightness parameter (L*), a greenness or redness parameter (a*), b blueness or yellowness parameter (b*), r reference sample, t tested sample.

Two biological and five technical replicates were considered for color analysis. The results of lightness, greenness, or redness, blueness or yellowness, chroma, and hue angle were reported as mean value ± standard deviation, whereas the results of ΔE were reported as mean value.

HS-SPME-GC/MS analysis of volatile components

To collect the volatile components from each sample, Headspace Solid-Phase Microextraction−Gas Chromatography/Mass Spectrometry (HS-SPME-GC/MS) analysis was used. Two g-aliquots of each flatbread sample were reduced into powder using a Cyclotec 1093 Sample Mill (Tecator, Hoganas, Sweden) and were placed in 10 mL glass vials and closed with a screw cap equipped with an elastomeric septum. A DVB/PDMS 65 µm fiber (Supelco/Sigma-Aldrich, Milan, Italy) was exposed for 20 min into the head space, previously thermostated at 45 °C for 10 min in a thermostatic water bath (M20 Lauda, Spectralab Scientific Inc., Ontario, Canada) [34]. To analyze the volatile profile of samples, a Trace 1300 gas chromatograph coupled with a ISQ 7000 single quadrupole mass spectrometer (Thermo Fisher Scientific, Waltham, MA, USA) and equipped with a Zebron ZB-5 ms capillary column 30 m × 0.25 mm i.d., 0.25 μm film thickness (Phenomenex, Torrance, CA, USA) was used. Thermal desorption of the compounds from the fiber took place in the GC injector at 250 °C for 5 min. As described by Foligni et al. [35], the injection was performed by applying the following parameters: oven temperature from 40 °C to 220 °C increased at a rate of 6 °C min−1 and maintained for 5 min; gas flow (He) in constant mode at 1.0 mL min−1 and full scan MS data acquired in the mass range of 31–250 atomic mass units (amu). Identification of volatile compounds was made by matching the mass spectral data with NIST/EPA/NIH Mass Spectral Library 2020 and the chromatographic behavior with published Kovats retention indices (RIs) according to Mozzon et al. [36]. An automated spreadsheet was used to simplify the calculation of RIs of the unknown components [37]. The total peak area of all the volatiles was assumed as 100% while collectively calculated classes of volatile compounds (peaks area sum) were calculated as the % of the total.

Statistical analyses

Tukey–Kramer’s Honest Significant Difference (HSD) test (P < 0.05) was used to evaluate differences within flat bread samples by one-way analysis of variance (ANOVA) using the software JMP v11.0.0 (SAS Institute Inc., Cary, NC) [38].

Spearman’s correlation analysis was performed to evidence co-occurrences and co-exclusions between volatile compounds using the psych package in R v4.2.0. Significant correlations (P < 0.05) were visualized using the corrplot package (R v4.2.0) [39].

Results

Bacterial composition of sourdoughs

The bacterial taxonomic groups of sourdough samples are reported in Fig. 2.

The microbial taxa Levilactobacillus brevis (14.44, 45.83, and 27.36% of the relative frequency in wheat sourdough, Polish buckwheat sourdough, and Italian buckwheat sourdough, respectively), Lactobacillus (17.05, 3.47, and 11.09% of the relative frequency in wheat sourdough, Polish buckwheat sourdough, and Italian buckwheat sourdough, respectively), and Lactiplantibacillus plantarum (19.27, 5.23, and 6.70% of the relative frequency in wheat sourdough, Polish buckwheat sourdough, and Italian buckwheat sourdough, respectively) were detected in all the samples. The species Limosilactobacillus reuteri was identified in wheat sourdough and Italian buckwheat sourdough, attesting at 43.65 and 8.45% of the relative frequency, respectively. The genus Pediococcus characterized both Italian and Polish buckwheat sourdoughs, with 42.04 and 40.92% of the relative frequency, respectively.

Microbial viable counts

The results of microbial viable counts of raw material, sourdough, dough, and flatbread samples are reported in Table 2.

The raw materials used for bread making showed highly heterogeneous results for each microbial group examined, as confirmed by the presence of numerous statistically significant differences among samples. In more detail, the total mesophilic aerobes were comprised between 3.03 ± 0.03 (Polish buckwheat flour) and 6.16 ± 0.04 Log cfu g−1 (Italian buckwheat flour). Presumptive lactobacilli were not detected in Polish buckwheat flour and durum wheat flour, whereas insect powder showed the highest average value attesting at 4.87 ± 0.11 Log cfu g−1. The counts of eumycetes ranged from 1.54 ± 0.09 (Polish buckwheat flour) and 4.09 ± 0.06 Log cfu g−1 (soft wheat flour). Bacterial spores were detected in all raw material samples with average values comprised between 1.39 ± 0.12 (Polish buckwheat flour) and 3.54 ± 0.10 Log cfu g−1 (insect powder).

As for sourdough samples, the statistical analysis showed significant differences for the total mesophilic aerobes, presumptive lactobacilli and eumycetes between wheat sourdough and buckwheat sourdoughs. In fact, wheat sourdough obtained lower values for the total mesophilic aerobes and presumptive lactobacilli attesting at 7.33 ± 0.03 and 8.82 ± 0.00 Log cfu g−1, respectively, whereas both Italian and Polish buckwheat sourdough samples obtained values above 9 Log cfu g−1 for the same microbial groups. Moreover, eumycetes were not detected in buckwheat sourdoughs, whereas the same microbial group reached counts of 7.43 ± 0.99 Log cfu g−1 in wheat sourdough. Counts of bacterial spores were statistically different among sourdough samples, with values comprised between 1.39 ± 0.12 in wheat sourdough and 2.36 ± 0.05 Log cfu g−1 in Italian buckwheat sourdough.

The total mesophilic aerobes of dough samples leavened with baker’s yeast showed statistically lower counts in respect to dough samples leavened with different types of sourdough, with values comprised between 4.50 ± 0.63 (POLB) and 9.78 ± 0.04 Log cfu g−1 (POLS). The same trend was observed for presumptive lactobacilli, with values ranging from 4.97 ± 0.04 (POLB) and 9.82 ± 0.05 Log cfu g−1 (POLS). On the contrary, dough samples leavened with baker’s yeast reached statistically higher values of eumycetes in respect to dough samples added with sourdoughs, with counts between 1.39 ± 0.12 (POLS) and 7.31 ± 0.05 Log cfu g−1 (WB). The counts of bacterial spores of dough samples were comprised between 2.08 ± 0.05 (WB) and 3.09 ± 0.02 Log cfu g−1 (POLB).

The experimental flatbread samples were analyzed for the presence of bacterial spores, with counts reaching the average highest value of 1.81 ± 0.00 Log cfu g−1 in sample FPOLS.

Physico-chemical measurements

The results of the physico-chemical measurements of sourdough, dough, and flatbread samples are reported in Table 2.

In more detail, pH values were comprised between 3.71 ± 0.01 (wheat sourdough) and 4.26 ± 0.01 (Italian buckwheat sourdough), whereas TTA values ranged from 16.1 ± 0.03 (Italian buckwheat sourdough) and 16.7 ± 0.8 mL of 0.1 N NaOH (wheat sourdough). The pH values of sourdough samples made with buckwheat flours showed statistically higher values in respect to those of sourdough samples made with wheat flour. The TTA values showed no statistically significant differences among sourdough samples.

As for dough samples, higher pH values were evidenced for doughs made with baker’s yeast respect to doughs made with sourdoughs. The lowest pH value (5.17 ± 0.01) was obtained from WS and the highest (5.81 ± 0.02) from POLB. The TTA results showed higher values for dough formulations comprising insect powder in respect to samples WB and WS. In detail, TTA values ranged from 3.5 ± 0.1 of sample WB to 12.2 ± 0.1 mL of 0.1 N NaOH of sample IS.

Regarding the experimental flatbread samples, those made with insect powder showed higher TTA values in respect to FWS and FWB. TTA values were comprised between 4.6 ± 0.7 (FWB) and 12.8 ± 0.8 mL of 0.1 N NaOH (FPOLS). The aw values of flatbread samples showed no statistically significant differences, apart from values of sample FWS resulting the lowest. In detail, aw results ranged from 0.638 ± 0.079 (FWS) and 0.777 ± 0.026 (FIB).

Baking loss, specific volume, and texture of bread

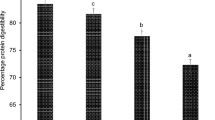

The results of baking loss, specific volume, and texture analyses on experimental flatbreads are reported in Fig. 3.

Results of baking loss a, specific volume b, and textural analysis c of experimental flatbread samples, Values are expressed as mean ± standard deviation. Means with different superscripts are significantly different (P < 0.05), FWB, flatbread samples made with baker’s yeast, FIB, flatbread samples made with baker’s yeast and cricket powder, FITAB, flatbread samples made with baker’s yeast, cricket powder, and Italian buckwheat flour, FPOLB, flatbread samples made with baker’s yeast, cricket powder, and Polish buckwheat flour, FWS, flatbread samples made with wheat sourdough, FIS, flatbread samples made with wheat sourdough and cricket powder, FITAS, flatbread samples made with Italian buckwheat sourdough, cricket powder, and Italian buckwheat flour, FPOLS, flatbread samples made with Polish buckwheat sourdough, cricket powder, and Polish buckwheat flour

The baking loss showed no significant statistically differences among samples, with values ranging from 19.68 ± 1.43 (FITAS) to 24.92 ± 3.29 (FIB).

As for the specific volume, no significant differences were highlighted by the statistical analysis, and the results were comprised between 1.58 ± 0.06 (FITAS) and 1.82 ± 0.29 (FWB).

The fracturability analysis showed that flatbread samples FWB and FWS obtained statistically higher values in respect to experimental flatbread samples added with cricket powder, with values ranging from 6.30 ± 0.61 (FITAS) and 13.83 ± 3.66 N (FWB).

Color analysis

The results of lightness, greenness/redness, blueness/yellowness, chroma, and hue angle of flour mixture, dough, and flatbread samples are reported in Supplementary Table 1. The results of ΔE are reported in Fig. 4.

Color difference (ΔE) results calculated from color analysis parameters. The color change between flour mixture samples added with cricket powder (MI, MITA, and MPOL) and flour mixture samples not containing insects (MW) (panel a), dough samples added with cricket powder made with bakers’ yeast (IB, ITAB, and POLB) or sourdough (IS, ITAS, and POLS) and samples not containing insects (WB or WS) (panel b), flatbread samples added with cricket powder made with bakers’ yeast (FIB, FITAB, and FPOLB) or sourdough (FIS, FITAS, and FPOLS) and samples not containing insects (FWB or FWS) (panel c) are showed. Values are expressed as mean. Means with different letters are significantly different (P < 0.05), MW, flour mixture samples used for production of flatbread not containing insects, MI, flour mixture samples used for production of flatbread added with cricket powder, MITA, flour mixture samples used for production of flatbread added with cricket powder and buckwheat flour obtained from Italian crops, MPOL, flour mixture samples used for production of flatbread added with cricket powder and buckwheat flour obtained from Polish crops, WB and FWB, dough and flatbread samples not containing insects made with baker’s yeast, IB and FIB, dough and flatbread samples made with baker’s yeast and cricket powder, ITAB and FITAB, dough and flatbread samples made with baker’s yeast, cricket powder, and Italian buckwheat flour, POLB and FPOLB, dough and flatbread samples made with baker’s yeast, cricket powder, and Polish buckwheat flour, WS and FWS, dough and flatbread samples not containing insects made with wheat sourdough, IS and FIS, dough and flatbread samples made with wheat sourdough and cricket powder, ITAS and FITAS, dough and flatbread samples made with Italian buckwheat sourdough, cricket powder, and Italian buckwheat flour, POLS and FPOLS, dough and flatbread samples made with Polish buckwheat sourdough, cricket powder, and Polish buckwheat flour

The color change between flour mixture samples added with cricket powder and flour mixture samples not containing insect was comprised between 14.38 (MPOL) and 15.65 (MI), with no significant statistically differences among them.

As regards doughs, the color variation between samples added with cricket powder and samples not containing insect ranged between 18.66 (IB) and 19.78 (POLB), and 17.14 (ITAS) and 17.54 (POLS) for samples added with baker’s yeast and sourdoughs, respectively. In both cases, no statistically significant differences were observed.

The color change between flatbread samples added with cricket powder and flatbread samples not containing insect ranged from 12.36 (FIB) to 12.74 (FITAB), and from 13.54 (FIS) to 14.94 (FPOLS) for samples added with baker’s yeast and sourdoughs, respectively. The statistical analysis did not evidence significant differences among samples.

HS-SPME−GC/MS analysis of volatile components

The analysis of the volatile components of the analyzed flatbread samples allowed to identify and quantify 23 volatile compounds belonging to 7 different classes (Fig. 5). In more detail, acids (octanoic acid, propanoic acid, butanoic acid), alkanes (dodecane, nonane,2,3-dimethyl-), alcohols (ethanol, ethenone,1-(2-furanyl)), aldehydes (2,4-decadienal, nonanal, benzeneacetaldehyde, benzaldehyde, 2-heptenal, heptanal, hexanal, pentanal, butanal-2-methyl, butanal-3-methyl), ketones (acetophenone, 2-heptanone, acetoin), terpens (limonene), and aromatic compounds (pyrazine,2-ethenyl-6-methyl, pyrazine,2,6-dimethyl) were identified (Table 3). Significant correlations of co-occurrences and co-exclusions between volatile compounds detected in experimental flatbread samples were also evidenced (Supplementary Fig. 1).

Discussion

The growing awareness of the consumers on the advantages of a proper nutrition is deeply modifying their demands. In the present study, the production of novel flatbread prototypes prepared with nonconventional ingredients such as house cricket powder, buckwheat flours, and sourdoughs obtained from wheat or buckwheat flours was experimented and evaluated through the analysis of microbiological, physico-chemical, volatile, textural and colorimetric parameters. To the authors’ knowledge, the combined use of the aforementioned ingredients for the production of flatbread was never investigated before.

The metataxonomic analysis performed on spontaneously fermented sourdough samples used for flatbread production allowed major and minor taxa to be identified. Lactobacillus spp., L. brevis, and L. plantarum were detected in all sourdough samples, irrespective of the raw material used. The occurrence of these microbial taxa in sourdough was extensively described in the scientific literature [40, 41]. In fact, in a systematic review summarizing the last thirty years of knowledge on sourdough fermentation [41], the Lactobacillus community was described as the most abundant, with L. brevis and L. plantarum among the most common representatives. The genus Pediococcus characterized the fermentation of buckwheat-based sourdoughs. The identification of Pediococcus spp. through culture-independent methods in this fermented matrix was already reported by Moroni et al. [22], dealing with the production of different laboratory scale gluten-free sourdoughs. Of note, the competitiveness of certain species of lactic acid bacteria during the spontaneous fermentation of sourdough depends on dough acidity levels [42]. In the present study, the significant higher pH values of buckwheat sourdough may have favored the adaptation of Pediococcus spp., described as less acid tolerant than Lactobacillus spp. [43].

The viable counts performed on the raw materials highlighted the highest loads of presumptive lactobacilli and bacterial spores in freeze-dried house cricket powder. The microbiological characterization of processed house cricket powder was already performed in various scientific studies with comparable results of lactic acid bacteria and bacterial spore levels over 5 Log cfu g−1 [4, 44]. It is worthy of mention that Vandeweyer et al. [45], and Klunder et al. [46] conducted microbiological analyses on fresh edible house cricket samples, and reported higher viable counts of total mesophilic aerobes, lactic acid bacteria, eumycetes, and spore-forming bacteria in respect to the present study, thus confirming the high variability in the microbiological composition this raw material. The analyzed buckwheat flours showed dissimilar results. In more detail, the Polish flour was characterized by rather limited microbial loads, whereas the Italian flour was characterized by the highest microbial counts of total mesophilic aerobes. As far as the authors are aware, the microbiological profile of buckwheat flour is barely described in the scientific literature, therefore further investigations are needed to clarify whether the discrepancies evidenced between Polish and Italian flour are related to the origin of the grains or raw material handling.

The viable counts of spontaneously fermented sourdoughs were in accordance with the microbiological characterization of the same matrices described in other scientific publications: on the one hand, the fermentation of wheat sourdough depends on a delicate balance between lactic acid bacteria and yeasts that cooperate through the metabolism of carbohydrates and nitrogen sources, and the synthesis of stimulatory or inhibitory compounds [47,48,49]; on the other hand, both buckwheat sourdoughs evidenced a remarkable lactic acid bacteria community, whereas eumycetes were not detected [22, 50,51,52]. The absence of yeasts and molds in buckwheat sourdough is attributable to the antimicrobial activities of flavonoids commonly found in the raw material, including rutin and tannins, as already reported by Moroni et al. [50].

The microbial composition of the doughs directly reflected the microbiological profile of the ingredients used in bread-making process. In more detail, dough samples leavened with baker’s yeast were characterized by increased eumycete counts, moreover, notable loads of lactic acid bacteria were observed in doughs made with sourdough. In addition, the lowest counts of eumycetes were observed in dough samples containing buckwheat sourdoughs.

As for flatbread samples, the occurrence of bacterial spores was shown in the formulations comprising cricket powder. Of note, among the raw materials, the insect powder was characterized by the highest load of bacterial spores; as a confirmation, dough samples added with the same ingredient regularly displayed increased bacterial spore counts. Of note, the detection of bacterial spores in edible insects and related products has repeatedly been reported in the scientific literature [45, 46, 53]. In fact, microbial quality traits of a wide variety of edible insects were examined by Fasolato et al. [54]. The results of the same study showed the constant detection of spore-forming bacteria with an overall mean of about 4 Log cfu g−1 and the delineation through phylogenetic analysis of three major cluster, namely Bacillus cereus, Bacillus thuringiensis, and Bacillus cytotoxicus [54]. Osimani et al. [4] investigated the presence of spore-forming microorganisms of bread added with house cricket powder and identified various Bacillus species, including Bacillus licheniformis and Bacillus subtilis. The aforementioned species include both alterative and foodborne pathogens that could represent a serious threat for consumers’ health. Although bacterial spore counts of insect-based flatbread samples analyzed in the present study remained at acceptable levels thanks to the baking conditions adopted, the application of technological treatments able to eradicate such a microbiological risk and preserve the nutritional quality of both the raw material and related end-products should be implemented [53, 55].

The analysis of physico-chemical parameters of sourdough (from wheat or buckwheat) samples showed results in accordance with pH and TTA values reported in other scientific studies. In more detail, the pH values of traditional sourdough generally range from 3.5 to 4.5 depending on the fermentative microbial species and the processing conditions adopted [47, 56]. Furthermore, research on the development of buckwheat sourdough reported pH levels comprised between 4.0 and 4.5 [22, 50]. It is noteworthy that ash and protein content of flours may directly influence the acidification degree of fermented sourdoughs [50]. Recently, Zhou et al. [57] explored the biological characteristics of gluten-free sourdough systems and indicated a higher buffering capacity of tartary buckwheat flour in respect to conventional wheat flour. Hence, the statistically significant differences of pH values between the sourdoughs produced in the present study can be associated to the diverse composition of wheat and buckwheat flour, the latter commonly richer in ash and protein. As for the TTA determination, the results of wheat sourdough were comparable with those reported by Fraberger et al. [58], and Gunduz et al. [59] regarding the evaluation of chemical properties of traditional sourdoughs, characterized by values ranging from 7.18 to 17.04, and from 14.10 to 17.00 mL of 0.1 N NaOH, respectively. Moreover, similar data were collected from scientific publications dealing with the production of buckwheat sourdoughs, whose TTA measurements were comprised between 15.00 and 17.04 mL of 0.1 N NaOH [22, 50]. The presence of abundant undissociated acids synthesized during sourdough fermentation are usually associated with several advantages attributed to the bread, including the improvement of nutritional properties and the acquisition of desired rheological and sensory characteristics [56, 60].

As for dough samples analyzed in the present study, pH results highlighted a clear separation between doughs added with baker’s yeast and doughs added with sourdoughs. Of note, Osimani et al. [4] reported similar pH values for conventional breads enriched with cricket powder and added with artificially inoculated wheat sourdough and baker’s yeast or just baker’s yeast, attesting at 5.38 and 5.78, respectively. The TTA measurements of dough and flatbread samples showed the same trend. On the one hand, sourdoughs confirmed their acidifying properties when included in the bread formulation; on the other hand, all samples containing cricket powder showed considerably higher TTA values. Insect powders are generally characterized by a consistent ash content that was previously reported to directly affecting the buffering capacity of food products [4].

Regarding the aw of flatbread samples, the results showed acceptable levels inhibiting the growth of spoilage and pathogenic bacteria and preventing the germination of bacterial spores, these latter detected in the analyzed products albeit with limited loads [61].

The amount of water evaporated from food products during baking is defined as baking loss. The baking loss results calculated in the present study showed higher values in respect to other scientific studies on flat bread available in the scientific literature [62, 63]. In more detail, wheat flatbread samples analyzed by Sharma, & Gujral [62] and Wani et al. [63] obtained baking loss values of 18.23 and 14.3%, respectively. Such a variation is ascribable to different baking conditions, which in the present study were characterized by higher temperatures and longer times. Noteworthy, the absence of significant statistically differences between flatbread samples added with cricket powder and flatbread samples FWB and FWS was in accordance with the findings of Gaglio et al. [64]. The latter evidencing similar baking loss values between bread produced with semolina and sourdough, and bread produced with semolina, sourdough, and different insect powders [64].

As regards the specific volume, associated with dough inflating ability and oven spring, the absence of significant variations among flatbread samples was presumably related to restricted leavening times applied during the production process, hence, the data will not be further discussed [65].

The flatbread samples’ hardness expresses the applied force needed to break them. Significant differences were evidenced among flatbread samples added with cricket powder and flatbread samples FWB and FWS. To the authors’ knowledge, no data on the fracturability features of flatbread samples containing edible insects are available in the scientific literature for further comparison. Noteworthy, the exoskeleton of insects commonly consists of chitin, this latter containing considerable amounts of dietary fibers [66]. A study conducted by Sharma, & Prabhasankar [67] was based on the incorporation of whole hempseed flour, notable source of fibers, in the traditional Indian flatbread chapati, a staple food of South Asian countries. In the same study, the force required to cut the experimental products was measured, and a clear correlation between whole hempseed flour and softness raise of chapati samples was highlighted [67]. More recently, Bilgic, & Sensoy [29] evaluated the effect of psyllium and cellulose fiber addition on the texture properties of crackers by applying the three-point bending textural test. The results indicated that dietary fiber was responsible for hardness decrease of experimental crackers [29]. Hence, the lower hardness values registered in the present study for flatbread samples prepared with house cricket powder were presumably correlated with their higher fiber content. As reported by Mehfooz et al. [68], the formation of elastic gluten network in bread doughs is disfavored by high amount of fiber, which interrupts linkages between proteins, and decrease water absorption, this latter essential for a proper interaction between gliadin and glutenin. As regards the addition of different buckwheat flours, considered as a gluten-free pseudocereal with a discrete fiber content, the fracturability analysis performed in this study did not evidence a direct impact on the hardness values. However, a recent evaluation of buckwheat flour addition on the texture properties of chapati samples conducted by Gomathi, & Parameshwari [15] suggested a diverse trend. In fact, the force required to cut chapati ribbons added with buckwheat flour was significantly lower in respect to control samples made with wheat flour [15]. A further evaluation of flatbread samples containing buckwheat flour as the sole non-conventional ingredient is thus required to define its role on the texture features of the end-products.

Consumer preferences when choosing a food largely depend on its appearance. In particular, color is one of most considered features of appearance that may also have an impact on flavor perception [69]. In the present study, the color change (ΔE) was calculated between each flour mixture, dough, or flatbread samples added with cricket powder and flatbread samples not containing insects to evaluate variations higher than 3 and thus perceptible to human eye [33]. The results evidenced a clear change attributable to cricket powder addition, thus confirming the results of numerous scientific studies dealing with the production of experimental breads enriched with insect-based ingredients [7, 16, 64, 70]. Noteworthy, the color variation of bread products through the addition of edible insects could represent an advantage during consumer selection of food. In fact, the darker colors of such baking goods were compared by several authors to those of whole grain products, often preferred due to excellent nutritional characteristics [71]. The absence of significant statistically differences between flour mixture, dough, or flatbread samples added with cricket powder suggest that buckwheat flours did not visibly shape color parameters. These outcomes were in contrast with the recent publications of Gomathi, & Parameshwari [15], and Brites et al. [72], investigating the sensory characteristics of pan breads and chapatis, respectively, added with buckwheat flour. Both studies reported significant decrease of lightness and yellowness parameters following the addition of this ingredient [15, 72]. It can be assumed that, in the present study, the absence of perceptible color variations after the addition of buckwheat flour was ascribable to the presence of insect powder, which limited the influence of other pigmented ingredients. This finding represents an advantage in the development of innovative foods, as buckwheat flour might replace greater quantities of wheat flour with no consequences on their final color.

Volatile compounds that characterize the aromatic profile of bread are very numerous (more than 540), and usually belong to different classes such as alcohols, aldehydes, esters, ketones, acids, pyrazines, furans, and sulfur compounds [73, 74]. Among these classes, only a few molecules have an impact on the volatile profile. The origin of volatile compounds that characterize bread can have different origins, as microbiological, lipid oxidation, caramelization of sugars and from thermal degradation process [73, 74]. Ethanol, which is partly lost during cooking, is produced by the microbial fermentation of sugars; whereas the formation of short-chain alcohols, fatty acids, esters, and carbonyl compounds are the results of secondary fermentation [73, 74]. Aldehydes such as hexanal, nonanal, octanal, heptanal, and 2-heptenal are instead produced by the lipid oxidation process [73, 74]. Furans, acetic acid, acetaldehyde, and other compounds are produced following the caramelization of sugars and following the thermal degradation process of sugars and amino acids [73, 74]. In the present study, hexanal and nonanal, markers of lipid oxidation, were significantly higher in flatbread samples FWB and FWS. Nonane,2,3-dimethyl was found in all samples containing insect powder, except from FIB. Acetophenone is a ketone that confers floral odors and was found only in the samples FITAB and FPOLB that were produced with baker’s yeast, buckwheat flour, and insect powder. Propanoic acid, that confers a pungent aroma, was only found in the sample FIS. 2,3-dimethyl-nonane was identified in the samples FITAB, FPOLB, FIS, FITAS and FPOLS, and its detection might be due to the presence of cricket powder into their formulation. Dodecane, providing a musk flavor note, was found only in the FPOLS sample, that was produced using Polish buckwheat and sourdough. Acetophenone was detected only in the FITAB and FPOLB samples, therefore its presence might be ascribed to the ingredients of these flatbreads consisting of cricket powder, buckwheat, and baker’s yeast. Acetophenone, from the ketone group, is a volatile compound with implications in the overall flavor of baked products and can be formed during Maillard reactions [75]. Its odor perception is pleasant, having musty, flowery, and almond characteristics. Among the volatiles, hexanal is the most abundant, providing pleasant grassy notes. Also relevant is the presence of butanal-2-methyl that confers chocolate, malt, and green flavor notes. Finally, pyrazines can be responsible for the roast aroma [76].

Conclusions

The ingredients used in the present study, namely cricket powder, buckwheat flours obtained from Italian or Polish crops, and sourdoughs obtained from wheat or buckwheat flours showed to be suitable for the production of novel flatbread formulations. This feasibility study demonstrated that experimental flatbread samples were generally characterized by acceptable microbiological counts. Worthy to mention that freeze-dried insect powder reached the highest loads of bacterial spores among raw materials, thus suggesting the application of ad hoc strategies to control this hazard throughout the food production chain. The low aw levels of flatbread samples embodied a key feature to prevent the proliferation of alterative and pathogenic microorganisms, and the germination of bacterial spores. As for textural parameters, flatbread samples added with insect powder obtained decreased hardness values presumably due to the high content of dietary fiber contained in this novel ingredient. The same samples also showed a marked color change with darker tones in respect to samples that did not contain insects, thus representing a potential advantage during food choice by consumers. Of note, the addition of buckwheat flours did not cause hardness reduction or color variation of flatbread samples. Finally, volatile component analysis highlighted numerous compounds associated with enzymatic activities and nonconventional ingredients. In view of a potential market placement of innovative flatbreads, further investigations are required to evaluate both their nutritional profile and consumer acceptability.

Data availability

Data are available upon request from the corresponding author.

References

Giacalone D, Jaeger SR (2023) Consumer acceptance of novel sustainable food technologies: a multi-country survey. J Clean Prod 13:7119. https://doi.org/10.1016/j.jclepro.2023.137119

Romano A, Ferranti P, Gallo V, Masi P (2021) New ingredients and alternatives to durum wheat semolina for a high quality dried pasta. Curr Opin Food Sci 41:249–259. https://doi.org/10.1016/j.cofs.2021.07.005

Boukid F (2022) Flatbread-a canvas for innovation: a review. Appl. Food Res. 2(1):100071. https://doi.org/10.1016/j.afres.2022.100071

Osimani A, Milanović V, Cardinali F, Roncolini A, Garofalo C, Clementi F, Pasquini M, Mozzon M, Foligni R, Raffaelli N, Zamporlini F, Aquilanti L (2018) Bread enriched with cricket powder (Acheta domesticus): a technological, microbiological and nutritional evaluation. IFSET 48:150–163. https://doi.org/10.1016/j.ifset.2018.06.007

Devi WD, Bonysana R, Kapesa K, Rai AK, Mukherjee PK, Rajashekar Y (2022) Potential of edible insects as source of functional foods: biotechnological approaches for improving functionality. Syst Microbiol Biomanuf 2:461–472. https://doi.org/10.1007/s43393-022-00089-5

Regulation (EU) 2015/2283 of the European Parliament and of the Council of 25 November 2015 on novel foods, amending Regulation (EU) No 1169/2011 of the European Parliament and of the Council and repealing Regulation (EC) No 258/97 of the European Parliament and of the Council and Commission Regulation (EC) No 1852/2001. Off. J. Euro. Union. http://eur-lex.europa.eu/legalcontent/EN/TXT/PDF/?uri=CELEX:32015R2283&from=EN. Accessed 18 Apr 2023

Roncolini A, Milanović V, Aquilanti L, Cardinali F, Garofalo C, Sabbatini R, Clementi F, Belleggia L, Pasquini M, Mozzon M, Foligni R, Trombetta MF, Haouet MH, Altissimi MS, Di Bella S, Piersanti A, Griffoni F, Reale A, Niro S, Osimani A (2020) Lesser mealworm (Alphitobius diaperinus) powder as a novel baking ingredient for manufacturing high-protein, mineral-dense snacks. Food Res Int 131:109031. https://doi.org/10.1016/j.foodres.2020.109031

Commission Implementing Regulation (EU) 2022/188 of 10 February 2022 authorising the placing on the market of frozen, dried and powder forms of Acheta domesticus as a novel food under Regulation (EU) 2015/2283 of the European Parliament and of the Council, and amending Commission Implementing Regulation (EU) 2017/2470. Off. J. Euro. Union. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32022R0188. Accessed 22 Apr 2023

Commission Implementing Regulation (EU) 2021/1975 of 12 November 2021 authorising the placing on the market of frozen, dried and powder forms of Locusta migratoria as a novel food under Regulation (EU) 2015/2283 of the European Parliament and of the Council and amending Commission Implementing Regulation (EU) 2017/2470. Off. J. Euro. Union. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32021R1975. Accessed 18 Apr 2023

Commission Implementing Regulation (EU) 2021/882 of 1 June 2021 authorising the placing on the market of dried Tenebrio molitor larva as a novel food under Regulation (EU) 2015/2283 of the European Parliament and of the Council, and amending Commission Implementing Regulation (EU) 2017/2470. Off. J. Euro. Union. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32021R0882. Accessed 18 Apr 2023

Commission Implementing Regulation (EU) 2022/169 of 8 February 2022 authorising the placing on the market of frozen, dried and powder forms of yellow mealworm (Tenebrio molitor larva) as a novel food under Regulation (EU) 2015/2283 of the European Parliament and of the Council, and amending Commission Implementing Regulation (EU) 2017/2470. Off. J. Euro. Union. https://eur-lex.europa.eu/eli/reg_impl/2022/169. Accessed 18 Apr 2023

Commission Implementing Regulation (EU) 2023/5 of 3 January 2023 authorising the placing on the market of Acheta domesticus (house cricket) partially defatted powder as a novel food and amending Implementing Regulation (EU) 2017/2470. Off. J. Euro. Union. https://eur-lex.europa.eu/eli/reg_impl/2023/5/oj. Accessed 18 Apr 2023

Commission Implementing Regulation (EU) 2023/58 of 5 January 2023 authorising the placing on the market of the frozen, paste, dried and powder forms of Alphitobius diaperinus larvae (lesser mealworm) as a novel food and amending Implementing Regulation (EU) 2017/2470. Off. J. Euro. Union. https://eur-lex.europa.eu/eli/reg_impl/2023/58/oj. Accessed 18 Apr 2023

Giménez-Bastida JA, Zieliński H (2015) Buckwheat as a functional food and its effects on health. J Agric Food Chem 63(36):7896–7913. https://doi.org/10.1021/acs.jafc.5b02498

Gomathi GK, Parameshwari S (2022) Evaluation of buckwheat flour addition on the sensory, nutritional and materialistic properties analysis of Indian flat bread. Mater Today: Proc. https://doi.org/10.1016/j.matpr.2022.04.778

Roncolini A, Milanović V, Cardinali F, Osimani A, Garofalo C, Sabbatini R, Clementi F, Pasquini M, Mozzon M, Foligni R, Raffaelli N, Zamporlini F, Minazzato G, Trombetta MF, Van Buitenen A, Van Campenhout L, Aquilanti L (2019) Protein fortification with mealworm (Tenebrio molitor L.) powder: effect on textural, microbiological, nutritional and sensory features of bread. PLoS ONE 14(2):0211747. https://doi.org/10.1371/journal.pone.0211747

Milanović V, Osimani A, Garofalo C, Belleggia L, Maoloni A, Cardinali F, Mozzon M, Foligni R, Aquilanti L, Clementi F (2020) Selection of cereal-sourced lactic acid bacteria as candidate starters for the baking industry. PLoS ONE 15(7):e0236190. https://doi.org/10.1371/journal.pone.0236190

Cardinali F, Garofalo C, Reale A, Boscaino F, Osimani A, Milanović V, Taccari M, Aquilanti L (2022) Liquid sourdough from stone-ground soft wheat (Triticum aestivum) flour: development and exploitation in the breadmaking process. Food Res Int 161:111796. https://doi.org/10.1016/j.foodres.2022.111796

Canesin MR, Cazarin CBB (2021) Nutritional quality and nutrient bioaccessibility in sourdough bread. Curr Opin Food Sci 40:81–86. https://doi.org/10.1016/j.cofs.2021.02.007

Gobbetti M, De Angelis M, Di Cagno R, Calasso M, Archetti G, Rizzello CG (2019) Novel insights on the functional/nutritional features of the sourdough fermentation. Int J Food Microbiol 302:103–113. https://doi.org/10.1016/j.ijfoodmicro.2018.05.018

Yu Y, Wang L, Qian H, Zhang H, Qi X (2018) Contribution of spontaneously-fermented sourdoughs with pear and navel orange for the bread-making. LWT 89:336–343. https://doi.org/10.1016/j.lwt.2017.11.001

Moroni AV, Arendt EK, Dal Bello F (2011) Biodiversity of lactic acid bacteria and yeasts in spontaneously-fermented buckwheat and teff sourdoughs. Food Microbiol 28(3):497–502. https://doi.org/10.1016/j.fm.2010.10.016

Klindworth A, Pruesse E, Schweer T, Peplies J, Quast C, Horn M, Glöckner FO (2013) Evaluation of general 16S ribosomal RNA gene PCR primers for classical and next-generation sequencing-based diversity studies. Nucleic Acids Res 41(1):e1. https://doi.org/10.1093/nar/gks808

Caporaso JG, Kuczynski J, Stombaugh J, Bittinger K, Bushman FD, Costello EK, Fierer N, Peña AG, Goodrich JK, Gordon JI, Huttley GA, Kelley ST, Knights D, Koenig JE, Ley RE, Lozupone CA, McDonald D, Muegge BD, Pirrung M, Reeder J, Sevinsky JR, Turnbaugh PJ, Walters WA, Widmann J, Yatsunenko T, Zaneveld J, Knight R (2010) QIIME allows analysis of high-throughput community sequencing data. Nat Methods 7(5):335–336. https://doi.org/10.1038/nmeth.f.303

Edgar RC, Haas BJ, Clemente JC, Quince C, Knight R (2011) UCHIME improves sensitivity and speed of chimera detection. Bioinform 27:2194–2200. https://doi.org/10.1093/bioinformatics/btr381

Magoč T, Salzberg SL (2011) FLASH: fast length adjustment of short reads to improve genome assemblies. Bioinform 27(21):2957–2963. https://doi.org/10.1093/bioinformatics/btr507

Bolyen E, Rideout JR, Dillon MR, Bokulich NA, Abnet CC, Al-Ghalith GA, Alexander H, Alm EJ, Arumugam M, Asnicar F, Bai Y, Bisanz JE, Bittinger K, Brejnrod A, Brislawn CJ, Brown CT, Callahan BJ, Caraballo-Rodríguez AM, Chase J, Cope EK, Da Silva R, Diener C, Dorrestein PC, Douglas GM, Durall DM, Duvallet C, Edwardson CF, Ernst M, Estaki M, Fouquier J, Gauglitz JM, Gibbons SM, Gibson DL, Gonzalez A, Gorlick K, Guo J, Hillmann B, Holmes S, Holste H, Huttenhower C, Huttley GA, Janssen S, Jarmusch AK, Jiang L, Kaehler BD, Kang KB, Keefe CR, Keim P, Kelley ST, Knights D, Koester I, Kosciolek T, Kreps J, Langille MGI, Lee J, Ley R, Liu YX, Loftfield E, Lozupone C, Maher M, Marotz C, Martin BD, McDonald D, McIver LJ, Melnik AV, Metcalf JL, Morgan SC, Morton JT, Naimey AT, Navas-Molina JA, Nothias LF, Orchanian SB, Pearson T, Peoples SL, Petras D, Preuss ML, Pruesse E, Rasmussen LB, Rivers A, Robeson MS 2nd, Rosenthal P, Segata N, Shaffer M, Shiffer A, Sinha R, Song SJ, Spear JR, Swafford AD, Thompson LR, Torres PJ, Trinh P, Tripathi A, Turnbaugh PJ, Ul-Hasan S, van der Hooft JJJ, Vargas F, Vázquez-Baeza Y, Vogtmann E, von Hippel M, Walters W, Wan Y, Wang M, Warren J, Weber KC, Williamson CHD, Willis AD, Xu ZZ, Zaneveld JR, Zhang Y, Zhu Q, Knight R, Caporaso JG (2019) Reproducible, interactive, scalable and extensible microbiome data science using QIIME 2. Nat Biotechnol 37(8):852–857. https://doi.org/10.1038/s41587-019-0209-9

AACC Method 10–05.01 (2010) Guidelines for Measurement of Volume by Rapeseed Displacement. Doi: https://doi.org/10.1094/AACCIntMethod-10-05.01. Accessed 18 Apr 2023

Bilgic H, Sensoy H (2023) Effect of psyllium and cellulose fiber addition on the structure and the starch digestibility of bread and crackers. Food Struct 35:100302. https://doi.org/10.1016/j.foostr.2022.100302

Dick M, Limberger C, Thys RCS, Rios AdO, Flôres SH (2020) Mucilage and cladode flour from cactus (Opuntia monacantha) as alternative ingredients in gluten-free crackers. Food Chem 314:126178. https://doi.org/10.1016/j.foodchem.2020.126178

Aldughpassi A, Alkandari S, Alkandari D, Al-Hassawi F, Sidhu JS, Al-Amiri HA, Al-Salem E (2021) Effect of psyllium fiber addition on the quality of Arabic flatbread (Pita) produced in a commercial bakery. Ann Agric Sci 66(2):115–120. https://doi.org/10.1016/j.aoas.2021.08.002

Abebe W, Ronda F (2014) Rheological and textural properties of tef [Eragrostis tef (Zucc) Trotter] grain flour gels. J Cereal Sci 60(1):122–130. https://doi.org/10.1016/j.jcs.2014.02.001

Mau J-L, Lee C-C, Yang C-W, Chen R-W, Zhang Q-F, Lin S-D (2020) Physicochemical, antioxidant and sensory characteristics of bread partially substituted with aerial parts of sweet potato. LWT 117:108602. https://doi.org/10.1016/j.lwt.2019.108602

Belleggia L, Aquilanti L, Ferrocino I, Milanović V, Garofalo C, Clementi F, Cocolin L, Mozzon M, Foligni R, Haouet MN, Scuota S, Framboas M, Osimani A (2020) Discovering microbiota and volatile compounds of surströmming, the traditional Swedish sour herring. Food Microbiol 91:103503. https://doi.org/10.1016/j.fm.2020.103503

Foligni R, Mannozzi C, Ismaiel L, Capelli F, Laurita R, Tappi S, Dalla Rosa M, Mozzon M (2022) Impact of cold atmospheric plasma (cap) treatments on the oxidation of pistachio kernel lipids. Foods 11(3):419. https://doi.org/10.3390/foods11030419

Mozzon M, Foligni R, Mannozzi C (2020) Brewing quality of hop varieties cultivated in central Italy based on multivolatile fingerprinting and bitter acid content. Foods 9:541. https://doi.org/10.3390/foods9050541

Maoloni A, Milanović V, Osimani A, Cardinali F, Garofalo C, Belleggia L, Foligni R, Mannozzi C, Mozzon M, Cirlini M, Spaggiari M, Reale A, Boscaino F, Di Renzo T, Haouet MN, Staccini B, Di Bella S, Aquilanti L (2021) Exploitation of sea fennel (Crithmum maritimum L) for manufacturing of novel high-value fermented preserves. Food Bioprod Process 127:174–197. https://doi.org/10.1016/j.fbp.2021.03.001

Cardinali F, Ferrocino I, Milanović V, Belleggia L, Corvaglia MR, Garofalo C, Foligni R, Mannozzi C, Mozzon M, Cocolin L, Osimani A, Aquilanti L (2021) Microbial communities and volatile profile of Queijo de Azeitão PDO cheese, a traditional Mediterranean thistle-curdled cheese from Portugal. Food Res Int 147:110537. https://doi.org/10.1016/j.foodres.2021.110537

Cesaro C, Mannozzi C, Lepre A, Ferrocino I, Corsi L, Franciosa I, Belleggia L, Milanović V, Cardinali F, Garofalo C, Cocolin L, Aquilanti L, Ruschioni S, Isidoro N, Riolo P, Osimani A (2022) Fate of Escherichia coli artificially inoculated in Tenebrio molitor L larvae rearing chain for human consumption. Food Res Int 157:111269. https://doi.org/10.1016/j.foodres.2022.111269

De Vuyst L, Vrancken G, Ravyts F, Rimaux T, Weckx S (2009) Biodiversity, ecological determinants, and metabolic exploitation of sourdough microbiota. Food Microbiol 26(7):666–675. https://doi.org/10.1016/j.fm.2009.07.012

Arora K, Ameur H, Polo A, Di Cagno R, Rizzello CG, Gobbetti M (2021) Thirty years of knowledge on sourdough fermentation: A systematic review. Trends Food Sci Technol 108:71–83. https://doi.org/10.1016/j.tifs.2020.12.008

Adepehin JO (2020) Microbial diversity and pasting properties of finger millet (Eleusine coracana), pearl millet (Pennisetum glaucum) and sorghum (Sorghum bicolor) sourdoughs. Food Biosci 37:100684. https://doi.org/10.1016/j.fbio.2020.100684

Weckx S, Van der Meulen R, Allemeersch J, Huys G, Vandamme P, Van Hummelen P, De Vuyst L (2010) Community dynamics of bacteria in sourdough fermentations as revealed by their metatranscriptome. Appl Environ Microbiol 76(16):5402–5408. https://doi.org/10.1128/AEM.00570-10

Garofalo C, Osimani A, Milanović V, Taccari M, Cardinali F, Aquilanti L, Riolo P, Ruschioni S, Isidoro N, Clementi F (2017) The microbiota of marketed processed edible insects as revealed by high-throughput sequencing. Food Microbiol 62:15–22. https://doi.org/10.1016/j.fm.2016.09.012

Vandeweyer D, Crauwels S, Lievens B, Van Campenhout L (2017) Microbial counts of mealworm larvae (Tenebrio molitor) and crickets (Acheta domesticus and Gryllodes sigillatus) from different rearing companies and different production batches. Int J Food Microbiol 242:13–18. https://doi.org/10.1016/j.ijfoodmicro.2016.11.007

Klunder HC, Wolkers-Rooijackers J, Korpela JM, Nout MJR (2012) Microbiological aspects of processing and storage of edible insects. Food Control 26(2):628–631. https://doi.org/10.1016/j.foodcont.2012.02.013

Minervini F, De Angelis M, Di Cagno R, Gobbetti M (2014) Ecological parameters influencing microbial diversity and stability of traditional sourdough. Int J Food Microbiol 171:136–146. https://doi.org/10.1016/j.ijfoodmicro.2013.11.021

Minervini F, Di Cagno R, Lattanzi A, De Angelis M, Antonielli L, Cardinali G, Cappelle S, Gobbetti M (2012) Lactic acid bacterium and yeast microbiotas of 19 sourdoughs used for traditional/typical italian breads: interactions between ingredients and microbial species diversity. Appl Environ Microbiol 78(4):1251–1264. https://doi.org/10.1128/AEM.07721-11

Lattanzi A, Minervini F, Di Cagno R, Diviccaro A, Antonielli L, Cardinali G, Cappelle S, De Angelis M, Gobbetti M (2013) The lactic acid bacteria and yeast microbiota of eighteen sourdoughs used for the manufacture of traditional Italian sweet leavened baked goods. Int J Food Microbiol 163(2–3):71–79. https://doi.org/10.1016/j.ijfoodmicro.2013.02.010

Moroni AV, Arendt EK, Morrissey JP, Dal Bello F (2010) Development of buckwheat and teff sourdoughs with the use of commercial starters. Int J Food Microbiol 142(1–2):142–148. https://doi.org/10.1016/j.ijfoodmicro.2010.06.014

Vogelmann SA, Seitter M, Singer U, Brandt MJ, Hertel C (2009) Adaptability of lactic acid bacteria and yeasts to sourdoughs prepared from cereals, pseudocereals and cassava and use of competitive strains as starters. Int J Food Microbiol 130(3):205–212. https://doi.org/10.1016/j.ijfoodmicro.2009.01.020

Ua-Arak T, Jakob F, Vogel RF (2016) Characterization of growth and exopolysaccharide production of selected acetic acid bacteria in buckwheat sourdoughs. Int J Food Microbiol 239:103–112. https://doi.org/10.1016/j.ijfoodmicro.2016.04.009

Osimani A, Aquilanti L (2021) Spore-forming bacteria in insect-based foods. Curr Opin Food Sci 37:112–117. https://doi.org/10.1016/j.cofs.2020.10.011

Fasolato L, Cardazzo B, Carraro L, Fontana F, Novelli E, Balzan S (2018) Edible processed insects from e-commerce: Food safety with a focus on the Bacillus cereus group. Food Microbiol 76:296–303. https://doi.org/10.1016/j.fm.2018.06.008

Garofalo C, Milanović V, Cardinali F, Aquilanti L, Clementi F, Osimani A (2019) Current knowledge on the microbiota of edible insects intended for human consumption: a state-of-the-art review. Food Res Int 125:108527. https://doi.org/10.1016/j.foodres.2019.108527

Fekri A, Torbati M, Khosrowshahi AY, Shamloo HB, Azadmard-Damirchi S (2020) Functional effects of phytate-degrading, probiotic lactic acid bacteria and yeast strains isolated from Iranian traditional sourdough on the technological and nutritional properties of whole wheat bread. Food Chem 306:125620. https://doi.org/10.1016/j.foodchem.2019.125620

Zhou Y, Ouyang B, Duan M, Lv X, Zhou X (2022) Biological characteristics of the gluten-free sourdough system fermented by Lactobacillus plantarum ST-III and its effect on dough quality and nutritional value during freezing. Food Chem 14:100350. https://doi.org/10.1016/j.fochx.2022.100350

Fraberger V, Unger C, Kummer C, Domig KJ (2020) Insights into microbial diversity of traditional Austrian sourdough. LWT 127:109358. https://doi.org/10.1016/j.lwt.2020.109358

Gunduz CPB, Agirman B, Gaglio R, Franciosi E, Francesca N, Settanni L, Erten H (2022) Evaluation of the variations in chemical and microbiological properties of the sourdoughs produced with selected lactic acid bacteria strains during fermentation. Food Chem 14:100357. https://doi.org/10.1016/j.fochx.2022.100357

Zotta T, Piraino P, Parente E, Salzano G, Ricciardi A (2008) Characterization of lactic acid bacteria isolated from sourdoughs for Cornetto, a traditional bread produced in Basilicata (Southern Italy). World J Microbiol Biotechnol 24(9):1785–1795. https://doi.org/10.1007/s11274-008-9671-0

Tapia MS, Alzamora SM, Chirife J (2020) Effects of water activity (aw) on microbial stability as a hurdle in food preservation water activity in foods: fundamentals and applications. Wiley-Blackwell Hoboken. https://doi.org/10.1002/9781118765982.ch14

Sharma B, Gujral HS (2019) Modulation in quality attributes of dough and starch digestibility of unleavened flat bread on replacing wheat flour with different minor millet flours. Int J Biol Macromol 141:117–124. https://doi.org/10.1016/j.ijbiomac.2019.08.252

Wani IA, Sogi DS, Sharma P, Gill BS (2016) Physicochemical and pasting properties of unleavened wheat flat bread (Chapatti) as affected by addition of pulse flour. Cogent Food Agric 2:1. https://doi.org/10.1080/23311932.2015.1124486

Gaglio R, Barbera M, Tesoriere L, Osimani A, Busetta G, Matraxia M, Attanzio A, Restivo I, Aquilanti L, Settanni L (2021) Sourdough “ciabatta” bread enriched with powdered insects: Physicochemical, microbiological, and simulated intestinal digesta functional properties. IFSET. 72:102755. https://doi.org/10.1016/j.ifset.2021.102755

Hejri-Zarifi S, Ahmadian-Kouchaksaraei Z, Pourfarzad A, Khodaparast MH (2013) Dough performance, quality and shelf life of flat bread supplemented with fractions of germinated date seed. J Food Sci Technol 51(12):3776–3784. https://doi.org/10.1007/s13197-013-0929-7

Lange KW, Nakamura Y (2021) Edible insects as future food: chances and challenges. J Future Foods 1(1):38–46. https://doi.org/10.1016/j.jfutfo.2021.10.001

Sharma S, Prabhasankar P (2021) Effect of whole hempseed flour incorporation on the rheological, microstructural and nutritional characteristics of chapati–Indian flatbread. LWT 137:110491. https://doi.org/10.1016/j.lwt.2020.110491

Mehfooz T, Ali TM, Arif S, Hasnain A (2018) Effect of barley husk addition on rheological, textural, thermal and sensory characteristics of traditional flat bread (chapatti). J Cereal Sci 79:376–382. https://doi.org/10.1016/j.jcs.2017.11.020

Porretta S (2021) Consumer-based new product development for the food industry. Royal Soc Chem London. https://doi.org/10.1039/9781839163333-00001

González CM, Garzón R, Rosell CM (2019) Insects as ingredients for bakery goods. a comparison study of H. illucens, A. domestica and T. molitor flours. IFSET 51:205–210. https://doi.org/10.1016/j.ifset.2018.03.021

Zielińska E, Pankiewicz U, Sujka M (2021) Nutritional, physiochemical, and biological value of muffins enriched with edible insects flour. Antioxidants 10(7):1122. https://doi.org/10.3390/antiox10071122

Brites LTGF, Rebellato AP, Meinhart AD, Godoy HT, Pallone JAL, Steel CJ (2022) Technological, sensory, nutritional and bioactive potential of pan breads produced with refined and whole grain buckwheat flours. Food Chem 13:100243. https://doi.org/10.1016/j.fochx.2022.100243

Dong Y, Karboune S (2021) A review of bread qualities and current strategies for bread bioprotection: Flavor, sensory, rheological, and textural attributes. Compr Rev Food Sci Food Saf 20:1937–1981. https://doi.org/10.1111/1541-4337.12717

Pico J, Bernal J, Gómez M (2015) Wheat bread aroma compounds in crumb and crust: a review. Food Res Int 75:200–215. https://doi.org/10.1016/j.foodres.2015.05.051

Chai D, Li C, Zhang X, Yang J, Liu L, Xu X, Du M, Wang Y, Chen Y, Dong L (2019) Analysis of volatile compounds from wheat flour in the heating process. Int J Food Eng. https://doi.org/10.1515/ijfe-2019-0252

Żołnierczyk AK, Szumny A (2021) Sensory and chemical characteristics of two insect species: Tenebrio molitor and Zophobas morio larvae affected by roasting processes. Molecules 26:2697. https://doi.org/10.3390/molecules26092697

Acknowledgements

This article has been written within the framework of the PROM Program for International Exchange of Doctoral Students and Academic Staff founded by the Polish National Agency for Academic Exchange—Contract No. PPI/PRO/2019/1/00049/U/00001. The project was financed by the Ministry of Science and Higher Education in Poland under the program “Regional Initiative of Excellence” 2019-2022 project number 015/RID/2018/19 total funding amount 10,721,040.00 PLN.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subject.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Belleggia, L., Foligni, R., Ferrocino, I. et al. Morphotextural, microbiological, and volatile characterization of flatbread containing cricket (Acheta domesticus) powder and buckwheat (Fagopyrum esculentum) flour. Eur Food Res Technol 249, 2777–2795 (2023). https://doi.org/10.1007/s00217-023-04327-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-023-04327-5