Abstract

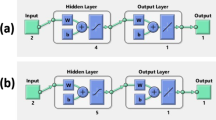

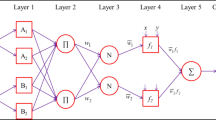

In this study, the effect of starch concentration (5, 7.5 and 10 %) and temperature (60, 70 and 80 °C) on the creep and recovery behaviour of grape molasses was investigated. Adaptive neuro-fuzzy inference system (ANFIS) and artificial neural network (ANN) models were established for the prediction of the compliance values (J(t)) based on temperature, starch concentration and time of the creep or recovery phases. The root mean square error, mean absolute error and R 2 values were used for the comparison of the models which showed that the ANFIS model performed better than the ANN model for the desired purpose. The Burger model fitted the J(t) versus time data with R 2 values ranging from 0.987 to 0.999. Response surface methodology (RSM) was performed to investigate the dependency of the creep (G 0 , G 1 , n 0 and n 1 ) and recovery (J KV , B, C, J max , J ∞ and % recovery) parameters to temperature and starch concentration. As a result of this study, it was observed that deformation of the grape molasses samples increased with decrease in starch concentration and increase in temperature. The gel strength (S) values of the samples were also calculated and modelled by RSM. As increase in starch concentration caused an increase in S value, there was an inverse proportion between the temperature and S value.

Similar content being viewed by others

References

Bozkurt H, Göğüş F, Eren S (1999) Nonenzymic browning reactions in boiled grape juice and IST models during storage. Food Chem 64:89–93

Goksel M, Dogan M, Toker OS, Ozgen S, Sarioglu K, Oral RA (2012) The effect of starch concentration and temperature on grape Molasses: rheological and textural properties. Food Bioprocess Technol 6:259–271

Dogan M (2007) Rheological and physicochemical characteristics of ice cream mix with molasses in a model system. Milchwissenchaft 62(2):195–198

Tabilo-Munigaza G, Barbosa-Cánovas GV (2005) Rheology for the food industry. J Food Eng 67:147–156

Barbosa-Cánovas GV, Kokini JL, Ma L, Ibarz A (1996) The rheology of semiliquid foods. Adv Food Nutr Res 39:1–69

Dolz M, Hernandez MJ, Delegido J (2008) Creep and recovery experimental investigation of low oil content food emulsions. Food Hydrocolloid 22:421–427

Campo L, Tovar C (2008) Influence of the starch content in the viscoelastic properties of surimi gels. J Food Eng 84:140–147

Jiménez-Avalos HA, Ramos-Ramírez EG, Salazar-Montoya JA (2005) Viscoelastic characterization of gum arabic and maize starch mixture using the Maxwell model. Carbonhyd Polym 62:11–18

Dogan M, Kayacier A, Toker ÖS, Yilmaz MT, Karaman S (2013) Steady, dynamic, creep, and recovery analysis of ice cream mixes added with different concentrations of xanthan gum. Food Bioprocess Technol. doi:10.1007/s11947-012-0872-z

Toker OS, Karaman S, Yuksel F, Dogan M, Kayacier A, Yilmaz MT (2013) Temperature dependency of steady, dynamic, and creep-recovery rheological properties of ice cream mix. Food Bioprocess Technol. doi:10.1007/s11947-012-1005-4

Sozer N (2009) Rheological properties of rice pasta dough supplemented with proteins and gums. Food Hydrocolloid 23:849–855

Yilmaz MT, Karaman S, Dogan M, Yetim H, Kayacier A (2012) Characterization of O/W model system meat emulsions using shear creep and creep recovery tests based on mechanical simulation models and their correlation with texture profile analysis (TPA) parameters. J Food Eng 108:327–336

Jang JSR, Sun CT (1995) Neuro-fuzzy modelling and control. P IEE 83:378–405

Ghoush MA, Samhouri M, Al-Holy M, Herald T (2008) Formulation and fuzzy modelling of emulsion stability and viscosity of a gum-protein emulsifier in a model mayonnaise system. J Food Eng 84:348–357

Karaman S, Kayacier A (2011) Effect of temperature on rheological characteristics of molasses: modeling of apparent viscosity using adaptive neuro fuzzy inference system (ANFIS). Food Sci Technol-LEB 44(8):1717–1725

Toker ÖS, Yılmaz MT, Karaman S, Doğan M, Kayacıer A (2012) Adaptive neuro-fuzzy inference system and artificial neural network estimation of apparent viscosity of ice cream mixes stabilized with different concentrations of xanthan gum. Appl Rheol 22:63918

Rahman MS, Rashid MM, Hussain MA (2012) Thermal conductivity prediction of foods by neural network and fuzzy (ANFIS) modeling techniques. Food and Bioprod Process. doi:10.1016/j.fbp.201107001

Toker OS, Dogan M, Goksel M (2012) Prediction of rheological parameters of model instant hot chocolate beverage by adaptive neuro fuzzy inference system. Milchwissenchaft 67(1):22–25

Zheng H, Jiang B, Lu H (2011) An adaptive neural-fuzzy inference system (ANFIS) for detection of bruises on Chinese bayberry (Mycrica rubra) based on fractal dimension and RGB intensity color. J Food Eng 104:663–667

Yalcin H, Toker OS, Ozturk I, Dogan M, Kisi O (2012) Prediction of fatty acid composition of vegetable oils based on rheological measurements using nonlinear models. Eur J Lipid Sci Tech 114:1217–1224

Abdullah AZ, Salamatinia B, Kamaruddin AH (2009) Application of response surface methodology for the optimization of NaOH treatment on oil palm frond towards improvement in the sorption of heavy metals. Desalination 244:227–238

Cobaner M, Unal B, Kisi O (2003) Suspended sediment concentration estimation by an adaptive neuro-fuzzy and neural approaches using hydro-meteorogical data. J Hydrolog Eng 367:52–61

Hagan MT, Menjah MB (1994) Training feed forward networks with the Marquaradt algorithm. IEE T Neural Netw 6:861–867

Kisi O (2007) Streamflow forecasting using different artificial neural network algorithms. J Hydrologic Eng 12:532–539

Wang L, Wang G, Zhang J, Zhang G, Jia L, Liu X, Deng P, Fan K (2011) Extraction optimization and antioxidant activity of intracellular selenium polysaccharide by Cordyceps sinensis SU-02. Carbonhyd Polym 86:1745–1750

Rao MA, Kash SF, Cooley HJ, Barnard J (1987) Desktop computer based collection and analysis of creep-compliance data on fluid foods. J Texture Stud 18:405–413

Ferry JD (1980) Viscoelastic properties of polymers, 3rd edn. Wiley, USA

Gladwell N, Rahalkar RR, Richmond P (1985) Creep/recovery behaviour of oil-water emulsions: influence of disperse phase concentration. J Food Sci 50:1477–1481

Schramm G (1994) A practical approach to rheology and rheometry. Gebrueder HAAKE GmbH, Federal Republic of Germany

Barnes HA (2000) A Handbook of Elementary Rheology. Institute of Non-Newtonian Fluid Mechanics/University of Wales, Aberystwyth/Wales

Steffe JF (1996) Rheological methods in food process engineering. Freeman Press, East Lansing

Barry BW (1983) In: Barry BW (ed) Rheology of dermatological vehicles. Marcel Dekker, New York

Vithanege CR, Grimson MJ, Smith BG, Wills PR (2011) Creep test observation of viscoelastic failure of edible fats. J Physics Conf Ser 286:012008. doi:10.1088/1742-6596/286/1/012008

Karazhiyan H, Razavi SMA, Philips GO (2011) Extraction optimization of a hydrocolloid extract from cress seed (Lepidium sativum) using response surface methodology. Food Hydrocolloid 25:915–920

Henika RG (1982) Use of response surface methodology in sensory evaluation. Food Technol Chic 36:96–101

Campos DT, Steffe JF, Ng PKW (1997) Rheological behaviour of undeveloped and developed wheat dough. Cereal Chem 74(4):489–494

Hayta M, Schofield JD (2005) Dynamic rheological behaviour of wheat glutens during heating. J Sci Food Agr 85:1992–1998

Tester RF, Sommerville MD (2003) The effects of non-starch polysaccharides on the extent of gelatinisation, swelling and a-amylase hydrolysis of maize and wheat starches. Food Hydrocolloid 17:41–54

Lazaridou A, Duta D, Papageorgiou M, Belc N, Biliaderis CG (2007) Effects of hydrocolloids on dough rheology and bread quality parameters in gluten free formulations. J Food Eng 79:1033–1047

Deman JM, Beers AM (1987) Fat crystal networks: structure and rheological properties. J Texture Stud 18:303–318

Nijenhus K (1997) Thermoreversible networks. Viscoelastic properties and structure of gels. Advanced in polymer sciences. Springer, Berlin

Nyström B, Kjøniksen A, Lindman B (1996) Effects of temperature, surfactant, and salt on the rheological behaviour in semidilute aqueous systems of a nonionic cellulose ether. Langmuir 12:3233–3240

Park JW (2000) Surimi and Surimi Seafood. Marcel Dekker, New York

Chen HH, Ferng LH, Chen SD, Sun WC, Lee YC (2005) Combination model for the spatial partition of surimi protein and hydroxylpropylmethylcellulose. Food Hydrocolloid 19:761–768

Kong CS, Ogawa H, Iso N (1999) Compression properties of fish meat gels affected by gelatinization of added starch. J Food Sci 64:283–286

Arslan E, Yener ME, Esin A (2005) Rheological characterization of tahin/pekmez (sesame paste/concentrated grape juice) blends. J Food Eng 69:167–172

Hassan BH, Hobani AI (1998) Flow properties of roselle (Hibiscus sabdariffa L.) extract. J Food Eng 35:459–470

Holdsworth SD (1971) Applicability of rheological models to the interpretation of flow and processing behaviour of fluid food products. J Texture Stud 2:393–418

Moresi M, Bruno M, Parente E (2004) Viscoelastic properties of microbial alginate gels by oscillatory dynamic tests. J Food Eng 64:179–186

Conflict of interest

None.

Compliance with Ethics Requirements

This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Toker, O.S., Dogan, M. Effect of temperature and starch concentration on the creep/recovery behaviour of the grape molasses: modelling with ANN, ANFIS and response surface methodology. Eur Food Res Technol 236, 1049–1061 (2013). https://doi.org/10.1007/s00217-013-1959-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-013-1959-0