Abstract

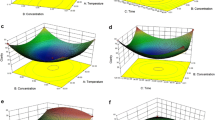

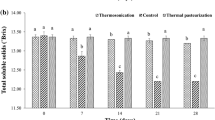

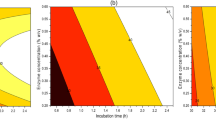

An innovative liquefaction process for the production of colouring foodstuff from purple pitaya was developed and optimized. Conducting an enzyme screening, the most suitable enzyme preparation for the liquefaction of pitaya pulp at low temperatures (4–12 °C) was selected allowing extensive viscosity reduction (50%) and high betalain retention (80%). A modified D-optimal design was used for the optimization of significant influence factors. Maximizing a heuristic optimization function composed of regression terms of the responses relative viscosity (R 2 = 0.97), betalain retention (R 2 = 0.88) and betanin–isobetanin retention (R 2 = 0.92), a numeric algorithm was established for process parameter optimization. The total juice yield was increased from 25–39 to 48–60% by implementation of the optimized liquefaction procedure into the pitaya juice production process. Mucilage separation steps were unnecessary and pitaya seeds could simply be separated as a by-product after juice filtration due to the extensive degradation of the mucilaginous matrix. In contrast to previously described mucilage liquefactions, the betalain profile was remarkably changed due to the applied enzymatic treatment resulting in a colour shift (Δh° = −14.7 ± 0.3) to bluish tones, and concentration of the so obtained pitaya juices from 12.3% TSS to 33% TSS and 65% TSS was successful at pilot plant scale.

Similar content being viewed by others

References

Wissgott U, Bortlik K (1996) Trends Food Sci Technol 7:298–302

McCann D, Barrett A, Cooper A, Crumpler D, Dalen L, Grimshaw K, Kitchin E, Lok K, Porteous L, Prince E, Sonuga-Barke E, Warner JO, Stevenson J (2007) Lancet 370:1560–1567

Stintzing FC, Carle R (2004) Trends Food Sci Technol 15:19–38

Santamaria P (2006) J Sci Food Agric 86:10–17

Acree TE, Lee CY, Butts RM, Barnard J (1976) J Agric Food Chem 24:430–431

Moßhammer M, Stintzing FC, Carle R (2005) Innov Food Sci Emerg Technol 6:221–231

Moßhammer M, Stintzing FC, Carle R (2006) Innov Food Sci Emerg Technol 7:275–287

Herbach KM, Maier C, Stintzing FC, Carle R (2007) Eur Food Res Technol 224:649–658

Sáenz C, Sepúlveda E, Matsuhiro B (2004) J Arid Environ 57:275–290

Stintzing FC, Carle R (2005) Mol Nutr Food Res 49:175–194

Paulsen BS, Lund PS (1979) Phytochemistry 18:569–571

Majdoub H, Roudesli S, Picton L, Le Cerl D, Muller G, Grisel M (2001) Carbohydr Polym 46:69–79

Stintzing FC, Carle R (2007) Trends Food Sci Technol 18:514–525

Esquivel P, Stintzing FC, Carle R (2007) J Appl Bot 81:7–14

Herjavec S, Jeromel A, Prusina T, Maslov L (2008) J Cent Eur Agric 9:505–510

Schweiggert U, Hofmann S, Reichel M, Schieber A, Carle R (2007) J Food Eng 84:28–38

Maier T, Göppert A, Kammerer DR, Schieber A, Carle R (2008) Eur Food Res Technol 227:267–275

Stintzing FC, Schieber A, Carle R (2003) Eur Food Res Technol 216:303–311

Esquivel P, Stintzing FC, Carle R (2007) Innov Food Sci Emerg Technol 8:451–457

Herbach KM, Rohe M, Stintzing FC, Carle R (2006) Food Res Int 39:667–677

Pasch JH, von Elbe JH (1979) J Food Sci 44:72–81

Petersen H (1992) Grundlagen der Statistik und Statistischen Versuchsplanung Band II, Ecomed Verlagsgesellschaft, Landsberg/Lech

Wang C, Eufemi M, Turano C, Giartosio A (1996) Biochemistry 35:7299–7307

Gorinstein S, Zemser M, Vargas-Albores F, Ochoa JL, Paredes-Lopez O, Scheler C, Aksu S, Salnikow J (1999) J Prot Chem 18:239–247

Gong F, Liang YZ, Fung YS, Chau FT (2004) J Chromatogr A 1029:173–183

Stintzing FC, Schieber A, Carle R (2002) Food Chem 77:101–106

Czyżowska A, Klewicka E, Libudzisz Z (2006) Eur Food Res Technol 223:110–116

Ganda-Herrero F, Escribano J, Garca-Carmona F (2007) J Agric Food Chem 55:1546–1551

Herbach KM, Stintzing FC, Carle R (2004) J Food Sci 69:491–498

Herbach KM, Stintzing FC, Carle R (2006) J Agric Food Chem 54:390–398

Acknowledgments

The authors thank Ellen Hemme and François Raoul-Duval (SCRD, Le Havre, France) for financially supporting this study. One of the authors (R.M.S.) is grateful for a travel grant by the Eiselen Foundation (Ulm, Germany). We thank Prof. Dr. Franz Schweiggert (Institute of Applied Information Processing, University of Ulm) for mathematical assistance in developing the optimization algorithm and the fruitful discussions with Dr. Ute Schweiggert and Georg M. Weisz are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schweiggert, R.M., Villalobos-Gutierrez, M.G., Esquivel, P. et al. Development and optimization of low temperature enzyme-assisted liquefaction for the production of colouring foodstuff from purple pitaya (Hylocereus sp. [Weber] Britton & Rose). Eur Food Res Technol 230, 269–280 (2009). https://doi.org/10.1007/s00217-009-1167-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-009-1167-0