Abstract

Use of 3D printing for microfluidics is a rapidly growing area, with applications involving cell culture in these devices also becoming of interest. 3D printing can be used to create custom-designed devices that have complex features and integrate different material types in one device; however, there are fewer studies studying the ability to culture cells on the various substrates that are available. This work describes the effect of PolyJet 3D-printing technology on cell culture of two cell lines, bovine pulmonary artery endothelial cells (BPAECs) and Madin-Darby Canine Kidney (MDCK) cells, on two different types of printed materials (VeroClear or MED610). It was found that untreated devices, when used for studies of 1 day or more, led to unsuccessful culture. A variety of device treatment methodologies were investigated, with the most success coming from the use of sodium hydroxide/sodium metasilicate solution. Devices treated with this cleaning step resulted in culture of BPAECs and MDCK cells that were more similar to what is obtained in traditional culture flasks (in terms of cell morphology, viability, and cell density). LC–MS/MS analysis (via Orbitrap MS) was used to determine potential leachates from untreated devices. Finally, the use of a fiber scaffold in the devices was utilized to further evaluate the treatment methodology and to also demonstrate the ability to perform 3D culture in such devices. This study will be of use for researchers wanting to utilize these or other cell types in PolyJet-based 3D-printed devices.

Similar content being viewed by others

References

Anderson KB, Lockwood SY, Martin RS, Spence DM. A 3D printed fluidic device that enables integrated features. Anal Chem. 2013;85:5622–6.

Au AK, Huynh W, Horowitz LF, Folch A. 3D-printed microfluidics. Angew Chem Int Ed Engl. 2016;55:3862–81.

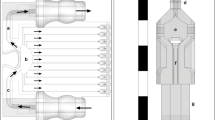

Castiaux AD, Pinger CW, Hayter EA, Bunn ME, Martin RS, Spence DM. PolyJet 3D-printed enclosed microfluidic channels without photocurable supports. Anal Chem. 2019;91:6910–7.

Chen C, Mehl BT, Munshi AS, Townsend AD, Spence DM, Martin RS. 3D-printed microfluidic devices: fabrication, advantages and limitations-a mini review. Anal Methods. 2016;8:6005–12.

Erkal JL, Selimovic A, Gross BC, Lockwood SY, Walton EL, McNamara S, et al. 3D printed microfluidic devices with integrated versatile and reusable electrodes. Lab Chip. 2014;14:2023–32.

Nielsen AV, Beauchamp MJ, Nordin GP, Woolley AT. 3D printed microfluidics. Annu Rev Anal Chem. 2020;13:45–65.

Ligon SC, Liska R, Stampfl J, Gurr M, Mülhaupt R. Polymers for 3D printing and customized additive manufacturing. Chem Rev. 2017;117:10212–90.

Macdonald NP, Cabot JM, Smejkal P, Guijt RM, Paull B, Breadmore MC. Comparing microfluidic performance of three-dimensional (3D) printing platforms. Anal Chem. 2017;89:3858–66.

Castiaux AD, Selemani MA, Ward MA, Martin RS. Fully 3D printed fluidic devices with integrated valves and pumps for flow injection analysis. Anal Methods. 2021;13:5017–24.

Castiaux AD, Spence DM, Martin RS. Review of 3D cell culture with analysis in microfluidic systems. Anal Methods. 2019;11:4220–32.

Price AK, Martin RS, Spence DM. Monitoring erythrocytes in a microchip channel that narrows uniformly: towards an improved microfluidic-based mimic of the microcirculation. J Chromatogr A. 2006;1111:220–7.

Rothbauer M, Zirath H, Ertl P. Recent advances in microfluidic technologies for cell-to-cell interaction studies. Lab Chip. 2018;18:249–70.

Kreß S, Schaller-Ammann R, Feiel J, Priedl J, Kasper C, Egger D. 3D Printing of cell culture devices: assessment and prevention of the cytotoxicity of photopolymers for stereolithography. Materials. 2020;13:3011.

Carve M, Wlodkowic D. 3D-printed chips: compatibility of additive manufacturing photopolymeric substrata with biological applications. Micromachines. 2018;9.

Lerman MJ, Lembong J, Gillen G, Fisher JP. 3D printing in cell culture. Appl Phys Rev. 2018;5:041109.

Ong LJY, Islam A, DasGupta R, Iyer NG, Leo HL, Toh YC. A 3D printed microfluidic perfusion device for multicellular spheroid cultures. Biofabrication. 2017;9:045005.

Wang YI, Abaci HE, Shuler ML. Microfluidic blood-brain barrier model provides in vivo-like barrier properties for drug permeability screening. Biotechnol Bioeng. 2017;114:184–94.

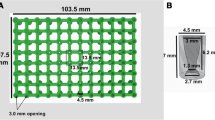

Chen C, Townsend AD, Sell SA, Martin RS. Microchip-based 3D-cell culture using polymer nanofibers generated by solution blow spinning. Anal Methods. 2017;9:3274–83.

Ngan CGY, O’Connell CD, Blanchard R, Boyd-Moss M, Williams RJ, Bourke J, et al. Optimising the biocompatibility of 3D printed photopolymer constructs in vitro and in vivo. Biomed Mater. 2019;14:035007.

Rimington RP, Capel AJ, Player DJ, Bibb RJ, Christie SDR, Lewis MP. Feasibility and biocompatibility of 3D-printed photopolymerized and laser sintered polymers for neuronal, myogenic, and hepatic cell types. Macromol Biosci. 2018;18:1800113.

Lu Z, Jiang X, Zuo X, Feng L. Improvement of cytocompatibility of 3D-printing resins for endothelial cell adhesion. RSC Adv. 2016;6:102381–8.

Warr C, Valdoz JC, Bickham BP, Knight CJ, Franks NA, Chartrand N, et al. Biocompatible PEGDA resin for 3D printing. ACS Appl Bio Mater. 2020;3:2239–44.

Genes LI, Tolan NV, Hulvey MK, Martin RS, Spence DM. Addressing a vascular endothelium array with blood components using underlying microfluidic channels. Lab Chip. 2007;7:1256–9.

Lockwood SY, Erkal JL, Spence DM. Endothelium-derived nitric oxide production is increased by ATP released from red blood cells incubated with hydroxyurea. Nitric Oxide. 2014;38:1–7.

Dukes JD, Whitley P, Chalmers AD. The MDCK variety pack: choosing the right strain. BMC Cell Biol. 2011;12:43.

Irvine JD, Takahashi L, Lockhart K, Cheong J, Tolan JW, Selick HE, et al. MDCK (Madin-Darby Canine Kidney) cells: a tool for membrane permeability screening. J Pharm Sci. 1999;88:28–33.

Data Sheet for Biocompatible Clear MED610, Stratasys: Eden Prairie, MN, https://www.stratasys.com/-/media/files/material-spec-sheets/mds_pj_med610_0720a.pdf?la=en&hash=A7AA885A72AC6B1BFD76B6E5BC8293BED36792DA. Accessed 20 Jan 2022.

WaterWorks Cleaning Solution; MSDS; SDS-400625 EN A, Stratasys: Eden Prairie, MN, 2020, https://www.stratasys.com/-/media/CE04AFBC656649BBBCE4C608059C194D.pdf. Accessed 20 Jan 2022.

Huang K, Castiaux A, Podicheti R, Rusch DB, Martin RS, Baker LA. A hybrid nanofiber/paper cell culture platform for building a 3D blood-brain barrier model. Small Methods. 2021;5.

Edwards JL, Edwards RL, Reid KR, Kennedy RT. Effect of decreasing column inner diameter and use of off-line two-dimensional chromatography on metabolite detection in complex mixtures. J Chromatogr A. 2007;1172:127–34.

Lai Z, Tsugawa H, Wohlgemuth G, Mehta S, Mueller M, Zheng Y, et al. Identifying metabolites by integrating metabolome databases with mass spectrometry cheminformatics. Nat Methods. 2018;15:53–6.

Millipore-Sigma, MTT assay protocol for cell viability and proliferation, https://www.sigmaaldrich.com/US/en/technical-documents/protocol/cell-culture-and-cell-culture-analysis/cell-counting-and-health-analysis/cell-proliferation-kit-i-mtt. Accessed 20 Jan 2022.

VeroClear RGD810 MSDS; SDS-06119 EN A, Stratasys: Eden Prairie, MN, 2021, https://www.stratasys.com/-/media/4514C58E09744D1A9F8425496B720C89.pdf. Accessed 20 Jan 2022.

Biocompatible MED610 MSDS; SDS-06192 EN A, Stratasys: Eden Prairie, MN, 2021, https://www.stratasys.com/-/media/A23CD2982A754E84910B3F7D9DB98CB3.PDF. Accessed 20 Jan 2022.

Naba A, Clauser KR, Ding H, Whittaker CA, Carr SA, Hynes RO. The extracellular matrix: tools and insights for the “omics” era. Matrix Biol. 2016;49:10–24.

Spence DM, Torrence NJ, Kovarik ML, Martin RS. Amperometric determination of nitric oxide derived from pulmonary artery endothelial cells immobilized in a microchip channel. Analyst. 2004;129:995–1000.

Sheetz MP, Felsenfeld DP, Galbraith CG. Cell migration: regulation of force on extracellular-matrix-integrin complexes. Trends Cell Biol. 1998;8:51–4.

Mahieu NG, Spalding JL, Gelman SJ, Patti GJ. Defining and detecting complex peak relationships in mass spectral data: the Mz.unity algorithm. Anal Chem. 2016;88:9037–46.

Chen CP, Mehl BT, Sell SA, Martin RS. Use of electrospinning and dynamic air focusing to create three-dimensional cell culture scaffolds in microfluidic devices. Analyst. 2016;141:5311–20.

Chen CP, Townsend AD, Hayter EA, Birk HM, Sell SA, Martin RS. Insert-based microfluidics for 3D cell culture with analysis. Anal Bioanal Chem. 2018;410:3025–35.

Acknowledgements

The authors would like to thank Dr. Dan Warren from the Department of Biology at Saint Louis University for access to the confocal microscope. The authors would like to acknowledge Saint Louis University’s Center for Additive Manufacturing (SLU-CAM) for providing access to the Stratasys PolyJet printers.

Funding

The research was funded by National Institutes of Health (2R15GM084470 05A1 and 1R01NS105888-01).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Currens, E.R., Armbruster, M.R., Castiaux, A.D. et al. Evaluation and optimization of PolyJet 3D-printed materials for cell culture studies. Anal Bioanal Chem 414, 3329–3339 (2022). https://doi.org/10.1007/s00216-022-03991-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-022-03991-y