Abstract

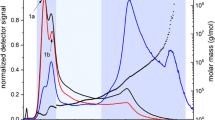

The macromolecular composition of beer is largely determined by the brewing and the mashing process. It is known that the physico-chemical properties of proteinaceous and polysaccharide molecules are closely related to the mechanism of foam stability. Three types of “American pale ale” style beer were prepared using different mashing protocols. The foam stability of the beers was assessed using the Derek Rudin standard method. Asymmetric flow field-flow fractionation (AF4) in combination with ultraviolet (UV), multiangle light scattering (MALS) and differential refractive index (dRI) detectors was used to separate the macromolecules present in the beers and the molar mass (M) and molar mass distributions (MD) were determined. Macromolecular components were identified by enzymatic treatments with β-glucanase and proteinase K. The MD of β-glucan ranged from 106 to 108 g/mol. In addition, correlation between the beer’s composition and foam stability was investigated (increased concentration of protein and β-glucan was associated with increased foam stability).

Similar content being viewed by others

References

Arnold JP. Origin and history of beer and brewing: From prehistoric times to the beginning of brewing science and technology; A critical essay. Alumni Ass'n of the Wahl-Henius Institute of Fermentology; 1911.

Michel RH, McGovern PE, Badler VR. Chemical evidence for ancient beer. Nature. 1992;360(6399):24. doi:10.1038/360024b0.

Max N. The Barbarian's Beverage: A History of Beer in Ancient Europe. 1st ed. Taylor & Francis; 2005.

Bamforth C. Beer: tap into the art and science of brewing. 3rd ed. Oxford University press; 2009.

Esslinger HM. Handbook of brewing: processes, technology, markets. Wiley; 2009.

Priest FG, Stewart GG. Handbook of brewing. CRC Press; 2006.

Asano K, Shinagawa K, Hashimoto N. Characterization of haze-forming proteins of beer and their roles in chill haze formation. J Am Soc Brew Chem. 1982;40(4):147–54. doi:10.1094/ASBCJ-40-0147.

Siebert KJ, Carrasco A, Lynn PY. Formation of protein–polyphenol haze in beverages. J Agric Food Chem. 1996;44(8):1997–2005. doi:10.1021/jf950716r.

Steiner E, Becker T, Gastl M. Turbidity and haze formation in beer—insights and overview. J Inst Brew. 2010;116(4):360–8.

Bamforth CW, Kanauchi M. Interactions between polypeptides derived from barley and other beer components in model foam systems. J Sci Food Agric. 2003;83(10):1045–50. doi:10.1002/jsfa.1503.

Bamforth CW. The relative significance of physics and chemistry for beer foam excellence: theory and practice. J Inst Brew. 2004;110(4):259–66. doi:10.1002/j.2050-0416.2004.tb00620.x.

Bamforth CW. Foam: Practical Guides for Beer Quality. 1st ed. American Society of Brewing Chemists; 2012.

Munck L, Jorgensen K, Ruud-Hansen J, Hansen K. The EBC methods for determination of high molecular weight β-glucan in barley, malt, wort and beer. J Inst Brew. 1989;95(2):79–82. doi:10.1002/j.2050-0416.1989.tb04612.x.

Anderson I. The effect of β-glucan molecular weight on the sensitivity of dye binding assay procedures for β-glucan estimation. J Inst Brew. 1990;96(5):323–6. doi:10.1002/j.2050-0416.1990.tb01038.x.

Laštovičková M, Mazanec K, Benkovská D, Bobáľová J. Utilization of the linear mode of MALDI-TOF mass spectrometry in the study of glycation during the malting process. J Inst Brew. 2010;116(3):245–50. doi:10.1002/j.2050-0416.2010.tb00427.x.

Kim S, Inglett GE. Molecular weight and ionic strength dependence of fluorescence intensity of the Calcofluor/β-glucan complex in flow-injection analysis. J Food Compos Anal. 2006;19(5):466–72. doi:10.1016/j.jfca.2005.11.006.

Rübsam H, Gastl M, Becker T. Influence of the range of molecular weight distribution of beer components on the intensity of palate fullness. Eur Food Res Technol. 2013;236(1):65–75.

Tomasi I, Marconi O, Sileoni V, Perretti G. Validation of a high-performance size-exclusion chromatography method to determine and characterize β-glucans in beer wort using a triple-detector array. Food Chem. 2017;214:176–82. doi:10.1016/j.foodchem.2016.06.092.

Tügel I, Runyon JR, Gómez Galindo F, Nilsson L. Analysis of polysaccharide and proteinaceous macromolecules in beer using asymmetrical flow field-flow fractionation. J Inst Brew. 2015;121(1):44–8. doi:10.1002/jib.195.

Giddings JC. Field flow fractionation: a versatile method for the characterization of macromolecular and particulate materials. Anal Chem. 1981;53(11):1170A–8A.

Wahlund KG, Giddings JC. Properties of an asymmetrical flow field-flow fractionation channel having one permeable wall. Anal Chem. 1987;59(9):1332–9.

Nilsson L. Separation and characterization of food macromolecules using field-flow fractionation: a review. Food Hydrocoll. 2013;30(1):1–11. doi:10.1016/j.foodhyd.2012.04.007.

Rudin AD. Measurement of the foam stability of beers. J Inst Brew. 1957;63(6):506–9. doi:10.1002/j.2050-0416.1957.tb06291.x.

Håkansson A, Magnusson E, Bergenståhl B, Nilsson L. Hydrodynamic radius determination with asymmetrical flow field-flow fractionation using decaying cross-flows. Part I. A theoretical approach. J Chromatogr A. 2012;1253:120–6. doi:10.1016/j.chroma.2012.07.029.

Berry GC. Thermodynamic and conformational properties of polystyrene. I. Light-scattering studies on dilute solutions of linear polystyrenes. J Chem Phys. 1966;44(12):4550–64. doi:10.1063/1.1726673.

Andersson M, Wittgren B, Wahlund K-G. Accuracy in multiangle light scattering measurements for molar mass and radius estimations. Model Calculations and Experiments Anal Chem. 2003;75(16):4279–91. doi:10.1021/ac030128+.

Theisen A. Refractive increment data-book for polymer and biomolecular scientists: Nottingham University Press; 2000.

Steiner E, Gastl M, Becker T. Protein changes during malting and brewing with focus on haze and foam formation: a review. Eur Food Res Technol. 2011;232(2):191–204. doi:10.1007/s00217-010-1412-6.

Ulmius M, Önning G, Nilsson L. Solution behavior of barley β-glucan as studied with asymmetrical flow field-flow fractionation. Food Hydrocoll. 2012;26(1):175–80. doi:10.1016/j.foodhyd.2011.05.004.

Grimm A, Krüger E, Burchard W. Solution properties of β-D-(1, 3)(1, 4)-glucan isolated from beer. Carbohydr Polym. 1995;27(3):205–14. doi:10.1016/0144-8617(95)00056-D.

Myers MN, Giddings JC. Properties of the transition from normal to steric field-flow fractionation. Anal Chem. 1982;54(13):2284–9.

Acknowledgements

The authors acknowledge the support provided by the National Research Foundation (NRF) of Korea (NRF-2013K2A3A1000086 and NRF-2016R1A2B4012105), support from Hannam University Research Fund, and support from the Swedish foundation for international cooperation for research and higher education (STINT).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

There are no competing interests present and there are no patents, products in development or marketed products to declare. Furthermore, we agree with the policies on sharing data and materials, as in the guide for authors.

Electronic supplementary material

ESM 1

(PDF 94 kb)

Rights and permissions

About this article

Cite this article

Choi, J., Zielke, C., Nilsson, L. et al. Characterization of the molar mass distribution of macromolecules in beer for different mashing processes using asymmetric flow field-flow fractionation (AF4) coupled with multiple detectors. Anal Bioanal Chem 409, 4551–4558 (2017). https://doi.org/10.1007/s00216-017-0393-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-017-0393-8