Abstract

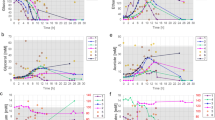

Wastes and by-products of the onion-processing industry pose an increasing disposal and environmental problem and represent a loss of valuable sources of nutrients. The present study focused on the production of vinegar from worthless onions as a potential valorisation route which could provide a viable solution to multiple disposal and environmental problems, simultaneously offering the possibility of converting waste materials into a useful food-grade product and of exploiting the unique properties and health benefits of onions. This study deals specifically with the second and definitive step of the onion vinegar production process: the efficient production of vinegar from onion waste by transforming onion ethanol, previously produced by alcoholic fermentation, into acetic acid via acetic fermentation. Near-infrared spectroscopy (NIRS), coupled with multivariate calibration methods, has been used to monitor the concentrations of both substrates and products in acetic fermentation. Separate partial least squares (PLS) regression models, correlating NIR spectral data of fermentation samples with each kinetic parameter studied, were developed. Wavelength selection was also performed applying the iterative predictor weighting–PLS (IPW-PLS) method in order to only consider significant spectral features in each model development to improve the quality of the final models constructed. Biomass, substrate (ethanol) and product (acetic acid) concentration were predicted in the acetic fermentation of onion alcohol with high accuracy using IPW-PLS models with a root-mean-square error of the residuals in external prediction (RMSEP) lower than 2.5% for both ethanol and acetic acid, and an RMSEP of 6.1% for total biomass concentration (a very satisfactory result considering the relatively low precision and accuracy associated with the reference method used for determining the latter). Thus, the simple and reliable calibration models proposed in this study suggest that they could be implemented in routine applications to monitor and predict the key species involved in the acetic fermentation of onion alcohol, allowing the onion vinegar production process to be controlled in real time.

Similar content being viewed by others

References

Rogers M (1995) Onions: a celebration of the onion through recipes, lore, and history. Addison-Wesley, New York

FAO Statistics (2005) Food and Agriculture Organization of the United Nations: agricultural production data. http://faostat.fao.org/site/567/default.aspx. Accessed 19 May 2008

Dorsch W, Scharff J, Bayer T, Wagner H (1989) Int Arch Allergy Appl Immunol 88:228–230

Hertog MGL, Hollman PCH (1996) Eur J Clin Nutr 50:63–71

Hollman PCH, Arts ICW (2000) J Sci Food Agric 80:1081–1093

Griffiths G, Trueman L, Crowther T, Thomas B, Smith B (2002) Phytother Res 16:603–615

Keusgen M (2002) Health and alliums. In: Rabinowitch HD, Currah L (eds) Advances in allium science. CABI, Wallingford

Waldron KW, Smith AC (1999) J Chem Technol Biotechnol 74:376–376

Aguilera Y, Mollá Lorente E, López Andreu FJ, Martín Cabrejas MA, Esteban Álvarez RM, Benítez V, González L (2006) Alimentaria 372:112–113

Horiuchi JI, Kanno T, Kobayashi M (1999) J Biosci Bioeng 88:107–109

Park YK, Jung ST, Kang SG, Park IB, Cheun KS, Kang SK (1999) Korean J Appl Microbiol Biotechnol 27:75–79

Horiuchi JI, Yamauchi N, Osugi M, Kanno T, Kobayashi M, Kuriyama H (2000) Bioresour Technol 75:153–156

Horiuchi JI, Kanno T, Kobayashi M (2000) J Biosci Bioeng 90:289–293

Horiuchi JI, Tada K, Kobayashi M, Kanno T, Ebie K (2004) Resour Conserv 40:97–109

Gardner NJ, Savard T, Obermeier P, Cladwell G, Champagne CP (2001) Int J Food Microbiol 64:261–275

Roberts JS, Kidd DR (2005) Lebensm – Wiss u Technol 38:185–190

Vaidyanathan S, Macaloney G, Vaughan J, McNeil B, Harvey LM (1999) Crit Rev Biotechnol 19:277–316

Vaidyanathan S, Arnold SA, Matheson L, Mohan P, McNeil B, Harvey LM (2001) Biotech Bioeng 74:376–388

Tosi S, Rossi M, Tamburini E, Vaccari G, Amaretti A, Mateuzzi D (2003) Biotechnol Prog 19:1816–1821

Garrido-Vidal D, Esteban-Díez I, Pérez-del-Notario N, González-Sáiz JM, Pizarro C (2004) J Near Infrared Spectrosc 12:15–27

Blanco M, Peinado AC, Mas J (2004) Biotechnol Bioeng 88:536–542

Ferreira AP, Alves TP, Menezes JC (2005) Biotechnol Bioeng 91:474–481

Blanco M, Peinado AC, Mas J (2006) Anal Chim Acta 556:364–373

Scarff M, Arnold SA, Harvey LM, McNeil B (2006) Crit Rev Biotechnol 26:17–39

González-Sáiz JM, Pizarro C, Esteban-Díez I, Ramírez O, González-Navarro CJ, Sáiz-Abajo MJ, Itoiz R (2007) J Agric Food Chem 55:2930–2936

Forina M, Casolino C, Pizarro C (1999) J Chemom 13:165–184

Singh A, Kuhad RC, Sahai V, Ghosh P (1994) Adv Biochem Eng Biotechnol 51:47–70

Forina M, Lanteri S, Armanino C, Cerrato-Oliveros MC, Casolino C (2004) V-PARVUS 2004, an extendable package of programs for explorative data analysis, classification and regression analysis. Dipartimento di Chimica e Tecnologie Farmaceutiche ed Alimentari, Università di Genova, Italy

Næs T, Isaksson T, Fearn T, Davies T (2004) A user-friendly guide to multivariate calibration and classification. NIR, Chichester

Acknowledgements

The authors thank the Spanish Government (Ministerio de Educación y Ciencia, Project No. AGL2003–09138-C04–04), the Autonomous Government of La Rioja (Plan Riojano de I+D+I, Projects No. ACPI-2004/02 and ACPI-2005) and the University of La Rioja for their financial support, as well as the CEBACAT (Asociación Catalana de Productores – Comercializadores de Cebolla) for providing the raw materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

González-Sáiz, J.M., Esteban-Díez, I., Sánchez-Gallardo, C. et al. Monitoring of substrate and product concentrations in acetic fermentation processes for onion vinegar production by NIR spectroscopy: value addition to worthless onions. Anal Bioanal Chem 391, 2937–2947 (2008). https://doi.org/10.1007/s00216-008-2186-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-008-2186-6