Abstract

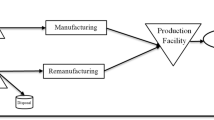

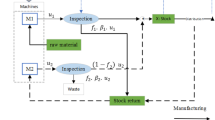

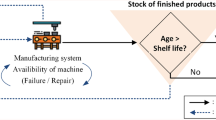

This paper deals with the problem of production planning and control (PPC) within hybrid manufacturing-remanufacturing systems (HMRSs), in which demand is fulfilled by either remanufacturing of returned items or manufacturing of new ones. It investigates how companies could benefit from changeable system settings with two production facilities operating in a stochastic and dynamic context. The rationale of such a system arises from its convertibility features that help to adapt the production process to internal (e.g., failures) and external (e.g., limited returned items) constraints. In this respect, we propose an integrated control policy that minimizes the long-term total cost by determining production and disposal rates as well as the switching strategy between manufacturing and remanufacturing modes. To tackle the problem, numerical techniques and optimal control theory are combined to characterize the control policy. A simulation-based approach is then used to optimize the resultant control parameters minimizing the total cost and to carry out sensitivity and comparative studies. The results illustrate the robustness of our approach showing its capability to assess the dynamic behaviour of integrated decisions and show that our proposal is more cost-effective compared to existing policies applied for different system settings with two facilities.

Similar content being viewed by others

Data availability

Data can be made available upon request.

References

D’Adamo I, Rosa P (2016) Remanufacturing in industry : advices from the field. Int J Adv Manuf Technol 86:2575–2584. https://doi.org/10.1007/s00170-016-8346-5

Fang C-C, Lai M-H, Huang Y-S (2017) Production planning of new and remanufacturing products in hybrid production systems. Comput Ind Eng 108:88–99. https://doi.org/10.1016/j.cie.2017.04.015

Teunter R, Kaparis K, Tang O (2008) Multi-product economic lot scheduling problem with separate production lines for manufacturing and remanufacturing. Eur J Oper Res 191:1241–1253. https://doi.org/10.1016/j.ejor.2007.08.003

Debo LG, Toktay LB, Van Wassenhove LN (2006) Joint life-cycle dynamics of new and remanufactured products. Prod Oper Manag 15:498–513. https://doi.org/10.1111/j.1937-5956.2006.tb00159.x

ElMaraghy HA, Wiendahl H-P (2009) Changeability – An Introduction BT - Changeable and reconfigurable manufacturing systems. In: ElMaraghy HA (ed). Springer London, London, 3–24

Koren Y, Gu X, Guo W (2018) Reconfigurable manufacturing systems: Principles, design, and future trends. Front Mech Eng 13:121–136. https://doi.org/10.1007/s11465-018-0483-0

Andersen A-L, Brunoe TD, Bockholt MT et al (2022) Changeable closed-loop manufacturing systems: challenges in product take-back and evaluation of reconfigurable solutions. Int J Prod Res 1–20.https://doi.org/10.1080/00207543.2021.2017504

Mehrabi MG, Ulsoy AG, Koren Y (2000) Reconfigurable manufacturing systems: key to future manufacturing. J Intell Manuf 11:403–419. https://doi.org/10.1023/A:1008930403506

Koren Y, Gu X, Badurdeen F, Jawahir IS (2018) Sustainable living factories for next generation manufacturing. Procedia Manuf 21:26–36

Francas D, Minner S (2009) Manufacturing network configuration in supply chains with product recovery. Omega 37:757–769. https://doi.org/10.1016/j.omega.2008.07.007

Macedo PB, Alem D, Santos M et al (2016) Hybrid manufacturing and remanufacturing lot-sizing problem with stochastic demand, return, and setup costs. Int J Adv Manuf Technol 82:1241–1257

Reddy KN, Kumar A (2021) Capacity investment and inventory planning for a hybrid manufacturing – remanufacturing system in the circular economy. Int J Prod Res 59:2450–2478. https://doi.org/10.1080/00207543.2020.1734681

van der Laan E, Salomon M, Dekker R, Van Wassenhove L (1999) Inventory control in hybrid systems with remanufacturing. Manage Sci 45:733–747

Kiesmüller GP (2003) A new approach for controlling a hybrid stochastic manufacturing/remanufacturing system with inventories and different leadtimes. Eur J Oper Res 147:62–71. https://doi.org/10.1016/S0377-2217(02)00351-X

Guo J, Ya G (2015) Optimal strategies for manufacturing/remanufacturing system with the consideration of recycled products. Comput Ind Eng 89:226–234. https://doi.org/10.1016/j.cie.2014.11.020

Kilic OA, Tunc H, Tarim SA (2018) Heuristic policies for the stochastic economic lot sizing problem with remanufacturing under service level constraints. Eur J Oper Res 267:1102–1109. https://doi.org/10.1016/j.ejor.2017.12.041

Liu W, Ma W, Hu Y et al (2019) Production planning for stochastic manufacturing/remanufacturing system with demand substitution using a hybrid ant colony system algorithm. J Clean Prod 213:999–1010. https://doi.org/10.1016/j.jclepro.2018.12.205

Wang X, Han S (2020) Optimal operation and subsidies/penalties strategies of a multi-period hybrid system with uncertain return under cap-and-trade policy. Comput Ind Eng 150:106892. https://doi.org/10.1016/j.cie.2020.106892

Bortolini M, Galizia FG, Mora C (2018) Reconfigurable manufacturing systems: Literature review and research trend. J Manuf Syst 49:93–106. https://doi.org/10.1016/j.jmsy.2018.09.005

Aljuneidi T, Bulgak AA (2016) A mathematical model for designing reconfigurable cellular hybrid manufacturing-remanufacturing systems. Int J Adv Manuf Technol 87:1585–1596. https://doi.org/10.1007/s00170-016-9141-z

Mejía-Moncayo C, Kenné J-P, Hof LA (2021) A hybrid architecture for a reconfigurable cellular remanufacturing system. In: IFIP International Conference on Advances in Production Management Systems. Springer, 488–496

Akella R, Kumar P (1986) Optimal control of production rate in a failure prone manufacturing system. IEEE Trans Automat Contr 31:116–126

Sajadi SM, Seyed Esfahani MM, Sörensen K (2011) Production control in a failure-prone manufacturing network using discrete event simulation and automated response surface methodology. Int J Adv Manuf Technol 53:35–46. https://doi.org/10.1007/s00170-010-2814-0

Corsini RR, Fichera S, Costa A (2022) Assessing the effect of a novel production control policy on a two-product, failure-prone manufacturing/distribution scenario. In: Carrino L, Tolio T (eds) Selected Topics in Manufacturing: AITeM Young Researcher Award 2021. Springer International Publishing, Cham, pp 1–20

MegozePongha P, Kibouka G-R, Kenné J-P, Hof LA (2022) Production, maintenance and quality inspection planning of a hybrid manufacturing/remanufacturing system under production rate-dependent deterioration. Int J Adv Manuf Technol 121:1289–1314. https://doi.org/10.1007/s00170-022-09078-3

Kenné JP, Dejax P, Gharbi A (2012) Production planning of a hybrid manufacturingremanufacturing system under uncertainty within a closed-loop supply chain. Int J Prod Econ 135:81–93. https://doi.org/10.1016/j.ijpe.2010.10.026

Kouedeu AF, Kenné J-P, Dejax P et al (2014) Production planning of a failure-prone manufacturing / remanufacturing system with production-dependent failure rates. Appl Math 5:1557–1572

Ouaret S, Kenné J-P, Gharbi A (2018) Stochastic optimal control of random quality deteriorating hybrid manufacturing/remanufacturing systems. J Manuf Syst 49:172–185. https://doi.org/10.1016/j.jmsy.2018.10.002

Hajej Z, Rezg N, Gharbi A (2020) Maintenance on leasing sales strategies for manufacturing/remanufacturing system with increasing failure rate and carbon emission. Int J Prod Res 58:6616–6637

Ndhaief N, Rezg N, Hajji A, Bistorin O (2020) Environmental issue in an integrated production and maintenance control of unreliable manufacturing/remanufacturing systems. Int J Prod Res 58:4182–4200

Korugan A, Dingeç KD, Önen T, Ateş NY (2013) On the quality variation impact of returns in remanufacturing. Comput Ind Eng 64:929–936

Turki S, Sauvey C, Rezg N (2018) Modelling and optimization of a manufacturing/remanufacturing system with storage facility under carbon cap and trade policy. J Clean Prod 193:441–458

Assid M, Gharbi A, Hajji A (2019) Production and setup control policy for unreliable hybrid manufacturing-remanufacturing systems. J Manuf Syst 50:103–118. https://doi.org/10.1016/j.jmsy.2018.12.004

Assid M, Gharbi A, Hajji A (2020) Production control of failure-prone manufacturing-remanufacturing systems using mixed dedicated and shared facilities. Int J Prod Econ 224:https://doi.org/10.1016/j.ijpe.2019.107549

Ross SM (2014) Introduction to probability models. Academic press, New York, NY, Eleventh e

Kleijnen JPC (2015) Design and analysis of simulation experiments. International Workshop on Simulation. Springer-Verlag, New York, NY, pp 3–22

Berthaut F, Gharbi A, Kenné J-P, Boulet J-F (2010) Improved joint preventive maintenance and hedging point policy. Int J Prod Econ 127:60–72

Kelton WD, Sadowski RP, Zupick NB (2015) Simulation with Arena. New York City

Montgomery DC (2012) Design and analysis of experiments, 8th edn. John Wiley & Sons, New York, NY

Sethi SP, Zhang Q (1994) Hierarchical decision making in stochastic manufacturing systems. Birkhäuser Boston, Boston, MA

Kushner HJ, Dupuis PG (1992) Numerical Methods for Stochastic Control Problems in Continuous Time. New York, NY

Hajji A, Gharbi A, Kenne JP (2004) Production and set-up control of a failure-prone manufacturing system. Int J Prod Res 42:1107–1130. https://doi.org/10.1080/00207540310001631575

Funding

This research was made with the support of the Natural Sciences and Engineering Research Council of Canada (NSERC). Grant numbers: RGPIN-2016–04484 and RGPIN-2020–05826.

Author information

Authors and Affiliations

Contributions

Conceptualization: A. Gharbi, A. Hajji, M. Assid; modeling: M. Assid; methodology and analysis: M. Assid, A. Gharbi, A. Hajji; validation: M. Assid, A. Gharbi, A. Hajji; writing: M. Assid; proof-reading and corrections: A. Gharbi, A. Hajji.

Corresponding author

Ethics declarations

Ethics approval

This study complies with the ethical standards and the committee on Publication Ethics (COPE) guidelines.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Appendix 1. Mathematical Formulation

1.1.1 Stochastic process

The stochastic process state \(\alpha \left(t\right)=\left({\alpha }_{1}\left(t\right),{\alpha }_{2}\left(t\right)\right)\) describe the operational mode of the entire production system composed of both facilities \({F}_{1}\) and \({F}_{2}\). Their operational mode at t could be given by the variables \({\alpha }_{1}\left(\mathrm{t}\right)\) and \({\alpha }_{2}\left(\mathrm{t}\right)\) taking values in \({M}_{1}=\left\{\mathrm{1,2}\right\}\) and \({M}_{2}=\left\{\mathrm{1,2}\right\}\), with:

From the definition of continuous-time discrete-state Markov chain [34], the stochastic processes \({\alpha }_{1}\left(\mathrm{t}\right)\) and \({\alpha }_{2}\left(\mathrm{t}\right)\) can be defined by the transition rates matrix denoted by \({\mathrm{T}}_{1}\) and \({\mathrm{T}}_{2}\), where \({\mathrm{T}}_{\mathrm{i}}=\left\{{q}_{\delta \vartheta }^{i}\right\}\), with \({q}_{\delta \vartheta }^{i}\ge 0\) if \(\vartheta \ne \delta\) and \({q}_{\delta \delta }^{i}=-\sum_{\delta \ne \vartheta }{q}_{\delta \vartheta }^{i}\), where \(\delta ,\vartheta \in {M}_{i}\).

We can derive the transition rate matrix of \(\alpha \left(\mathrm{t}\right)\) (\(T=\left\{{q}_{\delta \vartheta }\right\},\delta ,\vartheta \in M\)) from \({\mathrm{T}}_{\mathrm{i}}=\left\{{q}_{\delta \vartheta }^{i}\right\}\) as follows:

For the HMRS under study, the continuous and discrete state of the system is given by the three components vector \(\left({x}_{R},{x}_{F},\alpha \right)\), each component is subject to some constraints such that: \({x}_{R}\in \left[0,{x}_{R}^{esp}\right]\), \({x}_{F}\in R\) and \(\alpha \in M\). Let \(0\le {x}_{R}\left(t\right)\le {x}_{R}^{esp}\) the constraint of the storage space capacity, \(S=\left[0,{x}_{R}^{esp}\right]\) and \(\partial S=\left\{0,{x}_{R}^{esp}\right\}\), and let \({S}^{0}=\left]0,{x}_{R}^{esp}\right[\) be the interior of S.

1.1.2 Switching mode

The switching mode of the whole system can be described by the vector I taking values in \(M=\left\{\mathrm{1,2},\mathrm{3,4}\right\}\), where:

1.1.3 Admissible solution

Let A and \({\mathrm{A}}_{p}\) define the admissible decision sets \(\left({\Omega }_{1}, {\Omega }_{2},p\right)\):

1.1.4 Properties of the value function

By applying the dynamic programming principle as in [38], it can be shown that in the interior space \({S}^{0}\), the value function is the unique solution of the following optimality conditions (a set of coupled partial derivatives equations).

where \({v}_{x}\left(.\right)\), denotes the gradient of \({v}_{x}\left(.\right)\) With respect to \(x\).

1.2 Appendix 2. Numerical resolution

Following [39], we can apply the successive approximation algorithm or policy improvement techniques to solve the numerical approximation of (17).

Let \({\mathrm{h}}_{{\mathrm{x}}_{\mathrm{R}}}\) and \({\mathrm{h}}_{{\mathrm{x}}_{\mathrm{F}}}\) define the finite difference interval lengths of \({\mathrm{x}}_{\mathrm{R}}\) and \({\mathrm{x}}_{\mathrm{F}}\), respectively. Using the finite difference approximation, \({\mathrm{v}}_{\mathrm{i}}\left({\mathrm{x}}_{\mathrm{R}},{\mathrm{x}}_{\mathrm{F}},\mathrm{\alpha }\right)\) could be given by \({\left({\mathrm{v}}_{\mathrm{i}}\right)}^{{\mathrm{h}}_{{\mathrm{x}}_{\mathrm{R}}}}\left({\mathrm{x}}_{\mathrm{R}},{\mathrm{x}}_{\mathrm{F}},\mathrm{\alpha }\right)\), \({\left({\mathrm{v}}_{\mathrm{i}}\right)}^{{\mathrm{h}}_{{\mathrm{x}}_{\mathrm{F}}}}\left({\mathrm{x}}_{\mathrm{R}},{\mathrm{x}}_{\mathrm{F}},\mathrm{\alpha }\right)\) and the gradients \({\left({\mathrm{v}}_{\mathrm{i}}\right)}_{{\mathrm{x}}_{\mathrm{R}}}\left({\mathrm{x}}_{\mathrm{R}},{\mathrm{x}}_{\mathrm{F}},\mathrm{\alpha }\right)\) and \({\left({\mathrm{v}}_{\mathrm{i}}\right)}_{{\mathrm{x}}_{\mathrm{F}}}\left({\mathrm{x}}_{\mathrm{R}},{\mathrm{x}}_{\mathrm{F}},\mathrm{\alpha }\right)\) by:

Let: \({\uppsi }^{\mathrm{h}}\left({\mathrm{p}}_{1},{\mathrm{p}}_{2},\mathrm{\alpha },\uprho \right)=\uprho +\left|{\mathrm{q}}_{\mathrm{\alpha \alpha }}\right|+\frac{\left|{\mathrm{p}}_{1}\right|}{{\mathrm{h}}_{{\mathrm{x}}_{\mathrm{R}}}}+\frac{\left|{\mathrm{p}}_{2}\right|}{{\mathrm{h}}_{{\mathrm{x}}_{\mathrm{F}}}}\),

With, \({\mathrm{p}}_{1}={\mathrm{u}}_{\mathrm{R}}-{\mathrm{u}}_{2\mathrm{rem}}-{\mathrm{u}}_{1\mathrm{rem}}-{\mathrm{u}}_{\mathrm{dis}}\) and \({\mathrm{p}}_{2}={\mathrm{u}}_{1\mathrm{rem}}+{\mathrm{u}}_{1\mathrm{man}}+{\mathrm{u}}_{2\mathrm{rem}}+{\mathrm{u}}_{2\mathrm{man}}-\mathrm{d}\).

To simplify the notation, let \({h}_{{x}_{R}}={h}_{{x}_{F}}=h.\) Equation (A.1) can be expressed, in terms of \({\left({v}_{i}\right)}^{h}\left({x}_{R},{x}_{F},\alpha \right)\), as follows:

The use of a finite grid denoted by the computational domain CD is needed for the implementation of the successive approximation technique.

With \({x}_{R}^{sup}\) and \({x}_{F}^{sup}\) are given positive constants. For more details on the application of the successive approximation algorithm, we refer the reader to [40].

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Assid, M., Gharbi, A. & Hajji, A. Control policies of changeable manufacturing-remanufacturing systems using two failure-prone production facilities. Int J Adv Manuf Technol 125, 279–297 (2023). https://doi.org/10.1007/s00170-022-10664-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10664-8