Abstract

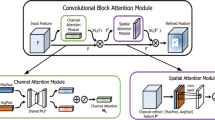

Fault diagnoses of rotating machinery (RM) have played an important role in the safety and reliability of contemporary sustainable manufacturing systems. Extracting features from original signal is a fundamental process for conventional fault recognition performance which needs human intervention and expert knowledge. This article introduces a Modified Moth Flame Optimization with Fuzzy Attention Deep Learning Enabled Fault Diagnosis (MMFO-FADLFD) Model for RMs for the identification and classification of faults. It follows empirical mode decomposition (EMD)–based signal decomposition and principal component analysis (PCA)–based feature reduction processes and fuzzy attention based bidirectional long short term memory (FA-BLSTM) model. Further, the MMFO algorithm is applied as a hyperparameter tuning technique for enhanced fault classification outcomes. The experimental validation of the MMFO-FADLFD model is tested using a dataset and the outcomes are examined under varying aspects and it confirms a promising performance of the MMFO-FADLFD model over other recent methods.

Similar content being viewed by others

References

Manikandan S, Duraivelu K (2021) Fault diagnosis of various rotating equipment using machine learning approaches–a review. Proc Inst Mech Eng Part E: J Process Mech Eng 235(2):629–642

Saha DK, Hoque ME, Badihi H (2022) Development of intelligent fault diagnosis technique of rotary machine element bearing: a machine learning approach. Sensors 22(3):1073

Tang S, Yuan S, Zhu Y (2019) Deep learning-based intelligent fault diagnosis methods toward rotating machinery. Leee Access 8:9335–9346

Almounajjed A, Sahoo AK, Kumar MK, Alsebai MD (2021) Investigation techniques for rolling bearing fault diagnosis using machine learning algorithms. In 2021 5th International Conference on Intelligent Computing and Control Systems (ICICCS). IEEE, pp 1290–1294

Zhao X, Jia M (2020) A novel unsupervised deep learning network for intelligent fault diagnosis of rotating machinery. Struct Health Monit 19(6):1745–1763

Chen Z, Mauricio A, Li W, Gryllias K (2020) A deep learning method for bearing fault diagnosis based on cyclic spectral coherence and convolutional neural networks. Mech Syst Signal Process 140:106683

Piltan F, Prosvirin AE, Jeong I, Im K, Kim JM (2019) Rolling-element bearing fault diagnosis using advanced machine learning-based observer. Appl Sci 9(24):5404

Mushtaq S, Islam MM, Sohaib M (2021) Deep learning aided data-driven fault diagnosis of rotatory machine: a comprehensive review. Energies 14(16):5150

Tran MQ, Elsisi M, Mahmoud K, Liu MK, Lehtonen M, Darwish MM (2021) Experimental setup for online fault diagnosis of induction machines via promising IoT and machine learning: towards industry 4.0 empowerment. IEEE access 9:115429–115441

Ince T, Malik J, Devecioglu OC, Kiranyaz S, Avci O, Eren L, Gabbouj M (2021) Early bearing fault diagnosis of rotating machinery by 1d self-organized operational neural networks. IEEE Access 9:139260–139270

Choudhary A, Mian T, Fatima S (2021) Convolutional neural network based bearing fault diagnosis of rotating machine using thermal images. Measurement 176:109196

Kolar D, Lisjak D, Pająk M, Gudlin M (2021) Intelligent fault diagnosis of rotary machinery by convolutional neural network with automatic hyper-parameters tuning using Bayesian optimization. Sensors 21(7):2411

Niu G, Wang X, Golda M, Mastro S, Zhang B (2021) An optimized adaptive PReLU-DBN for rolling element bearing fault diagnosis. Neurocomputing 445:26–34

Li G, Wu J, Deng C, Xu X, Shao X (2021) Deep reinforcement learning-based online domain adaptation method for fault diagnosis of rotating machinery. IEEE/ASME Trans Mechatronics

Lee YE, Kim BK, Bae JH, Kim KC (2021) Misalignment detection of a rotating machine shaft using a support vector machine learning algorithm. Int J Precis Eng Manuf 22(3):409–416

Tayyab SM, Asghar E, Pennacchi P, Chatterton S (2020) Intelligent fault diagnosis of rotating machine elements using machine learning through optimal features extraction and selection. Procedia Manuf 51:266–273

Dai W, Mo Z, Luo C, Jiang J, Zhang H, Miao Q (2020) Fault diagnosis of rotating machinery based on deep reinforcement learning and reciprocal of smoothness index. IEEE Sens J 20(15):8307–8315

Liu J, Zhou K, Yang C, Lu G (2021) Imbalanced fault diagnosis of rotating machinery using autoencoder-based SuperGraph feature learning. Front Mech Eng 16(4):829–839

Barbosh M, Singh P, Sadhu A (2020) Empirical mode decomposition and its variants: a review with applications in structural health monitoring. Smart Mater Struct 29(9):093001

Ejaz MS, Islam MR, Sifatullah M, Sarker A (2019) Implementation of principal component analysis on masked and non-masked face recognition. In 2019 1st international conference on advances in science, engineering and robotics technology (ICASERT) (pp. 1–5). IEEE

Lu H, Yang R, Deng Z, Zhang Y, Gao G, Lan R (2021) Chinese image captioning via fuzzy attention-based DenseNet-BiLSTM. ACM Trans Multimed Comput Commun Appl (TOMM) 17(1s):1–18

Mirjalili S (2015) Moth-flame optimization algorithm: a novel nature-inspired heuristic paradigm. Knowl-Based Syst 89:228–249

Shehab M, Abualigah L, Al Hamad H, Alabool H, Alshinwan M, Khasawneh AM (2020) Moth–flame optimization algorithm: variants and applications. Neural Comput Appl 32(14):9859–9884

Li LL, Wen SY, Tseng ML, Wang CS (2019) Renewable energy prediction: a novel short-term prediction model of photovoltaic output power. J Clean Prod 228:359–375

Funding

We deeply acknowledge Taif University for supporting this study through Taif University Researchers Supporting Project Number (TURSP- 2020/150), Taif University, Taif, Saudi Arabia.

Author information

Authors and Affiliations

Contributions

Author 1: Fawaz Alassery

☒Conceived and design the analysis.

☒ Collecting the Data.

☒ Wrote the Paper.

Author 2: Lamia Alhazmi

☒ Contributed data and analysis tools.

☒ Performed and analysis.

☒ Manuscript Editing and Figure Design.

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alassery, F., Alhazmi, L. Optimal fuzzy attention deep learning enabled rotating machine fault diagnosis for sustainable manufacturing. Int J Adv Manuf Technol (2022). https://doi.org/10.1007/s00170-022-10512-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00170-022-10512-9