Abstract

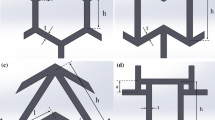

Selection of appropriate topology to use in the core of the sandwich structures is one of the serious challenges ahead to design of them. This study aims to investigate the influence of auxetic core topologies on the mechanical characteristics of fully integrated 3D printed polymeric sandwich structures. Specifically, three types of auxetic cores including square node anti-tetra chiral, re-entrant, and arrowhead were investigated and compared with the conventional honeycomb in terms of energy absorption, compressive strength, and Young’s modulus. The specimens were fabricated using FDM 3D printing method and quasi-static compression and low velocity impact loading tests were performed on the printed specimens. Moreover, finite element simulations were conducted to compare with experimental results and deformation patterns as well as for parametric study. Results indicate that the core topology is a critical parameter impressing the mechanical properties of sandwich structures, and using the auxetic cores improved the desirable properties of sandwich structures in both types of loading. Auxetic cores cause the sandwich structure to have more resistance to imported compression, while conventional honeycomb doesn’t have this superiority.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this manuscript.

References

Chen Y, Hou S, Fu K, Han X, Ye L (2017) Low-velocity impact response of composite sandwich structures: modelling and experiment. Compos Struct 168:322–334. https://doi.org/10.1016/j.compstruct.2017.02.064

Imbalzano G, Linforth S, Ngo TD, Lee PVS, Tran P (2018) Blast resistance of auxetic and honeycomb sandwich panels: comparisons and parametric designs. Compos Struct 183:242–261. https://doi.org/10.1016/j.compstruct.2017.03.018

Wang H, Ramakrishnan KR, Shankar K (2016) Experimental study of the medium velocity impact response of sandwich panels with different cores. Mater Des 99:68–82. https://doi.org/10.1016/j.matdes.2016.03.048

Qiao JX, Chen CQ (2015) Impact resistance of uniform and functionally graded auxetic double arrowhead honeycombs. Int J Impact Eng 83:47–58. https://doi.org/10.1016/j.ijimpeng.2015.04.005

Najafi M, Ahmadi H, Liaghat G (2021) Experimental investigation on energy absorption of auxetic structures. Mater Today Proc 34:350–355. https://doi.org/10.1016/j.matpr.2020.06.075

Wang Z, Liu J, Hui D (2017) Mechanical behaviors of inclined cell honeycomb structure subjected to compression. Compos Part B Eng 110:307–314. https://doi.org/10.1016/J.COMPOSITESB.2016.10.062

Tao Y, Duan S, Wen W, Pei Y, Fang D (2017) Enhanced out-of-plane crushing strength and energy absorption of in-plane graded honeycombs. Compos Part B Eng 118:33–40. https://doi.org/10.1016/J.COMPOSITESB.2017.03.002

Mohamadi Y, Ahmadi H, Razmkhah O, Liaghat G (2021) Axial crushing responses of aluminum honeycomb structures filled with elastomeric polyurethane foam. Thin-Walled Structures 164:107785. https://doi.org/10.1016/j.tws.2021.107785

Hassanpour Roudbeneh F, Liaghat G, Sabouri H, Hadavinia H (2019) Experimental investigation of impact loading on honeycomb sandwich panels filled with foam. Int J Crashworthiness 24:199–210. https://doi.org/10.1080/13588265.2018.1426233

Niknejad A, Liaghat GH, Moslemi Naeini H, Behravesh AH (2010) A theoretical formula for predicting the instantaneous folding force of the first fold in a single cell hexagonal honeycomb under axial loading. Proc Inst Mech Eng Part C J Mech Eng Sci 224:2308–2315. https://doi.org/10.1243/09544062JMES1979

Zhou L, Zeng J, Jiang L, Hu H (2018) Low-velocity impact properties of 3D auxetic textile composite. J Mater Sci 53:3899–3914. https://doi.org/10.1007/s10853-017-1789-8

Günaydin K, Eren Z, Scarpa F, Experimental investigation of auxetic structures subjected to quasi static axial load. (2017) 8th Int. Conf Recent Adv Sp Technol 2017:7–10. https://doi.org/10.1109/RAST.2017.8002986

Ju J, Summers JD (2011) Compliant hexagonal periodic lattice structures having both high shear strength and high shear strain. Mater Des 32:512–524. https://doi.org/10.1016/J.MATDES.2010.08.029

Ren X, Das R, Tran P, Ngo TD, Xie YM (2018) Auxetic metamaterials and structures: a review. Smart Mater Struct 27:23001. https://doi.org/10.1088/1361-665X/aaa61c

Mir M, Ali MN, Sami J, Ansari U (2014) Review of mechanics and applications of auxetic structures. Adv Mater Sci Eng 2014:1–18

Ren X, Shen J, Tran P, Ngo TD, Xie YM (2018) Auxetic nail: design and experimental study. Compos Struct 184:288–298. https://doi.org/10.1016/J.COMPSTRUCT.2017.10.013

Kolken HMA, Zadpoor AA (2017) Auxetic mechanical metamaterials RSC Adv 7:5111–5129. https://doi.org/10.1039/C6RA27333E

Zhang J, Lu G, You Z (2020) Large deformation and energy absorption of additively manufactured auxetic materials and structures: a review. Compos Part B Eng 201:108340. https://doi.org/10.1016/j.compositesb.2020.108340

Li T, Chen Y, Hu X, Li Y, Wang L (2018) Exploiting negative Poisson’s ratio to design 3D-printed composites with enhanced mechanical properties. Mater Des 142:247–258. https://doi.org/10.1016/j.matdes.2018.01.034

Najafi M, Ahmadi H, Liaghat G (2022) Investigation on the flexural properties of sandwich beams with auxetic core. J Braz Soc Mech Sci Eng 44:61. https://doi.org/10.1007/s40430-022-03368-3

Wu W, Tao Y, Xia Y, Chen J, Lei H, Sun L (2017) Mechanical properties of hierarchical anti-tetrachiral metastructures. Extrem Mech Lett 16:18–32. https://doi.org/10.1016/j.eml.2017.08.004

Doudaran MO, Ahmadi H, Liaghat G (2022) Crushing Performance of auxetic tubes under quasi-static and impact loading. J Braz Soc Mech Sci Eng 2022 Accepted. https://doi.org/10.1007/s40430-022-03539-2

Sarvestani HY, Akbarzadeh AH, Mirbolghasemi A, Hermenean K (2018) 3D printed meta-sandwich structures : failure mechanism, energy absorption and multi-hit capability face-sheets. Mater Des 160:179–193. https://doi.org/10.1016/j.matdes.2018.08.061

Lakes R (1987) Foam Structures with a negative Poisson’s ratio. Sci (80-) 235:1038 LP – 1040. https://doi.org/10.1126/science.235.4792.1038

Gibson LJ, Ashby MF (1997) Cellular solids: structure and properties. 2nd ed. Cambridge: Cambridge University Press. https://doi.org/10.1017/CBO9781139878326

Alomarah A, Masood SH, Sbarski I, Faisal B, Gao Z (2019) Compressive properties of 3D printed auxetic structures : experimental and numerical studies. Virtual Phys Prototyp 2759. https://doi.org/10.1080/17452759.2019.1644184

Rafsanjani A, Pasini D (2016) Bistable auxetic mechanical metamaterials inspired by ancient geometric motifs. Extrem Mech Lett 9:291–296. https://doi.org/10.1016/j.eml.2016.09.001

Safikhani Nasim M, Etemadi E (2018) Three dimensional modeling of warp and woof periodic auxetic cellular structure. Int J Mech Sci 136:475–481. https://doi.org/10.1016/j.ijmecsci.2018.01.002

Hamzehei R, Kadkhodapour J, Anaraki AP, Rezaei S, Dariushi S, Rezadoust AM (2018) Octagonal auxetic metamaterials with hyperelastic properties for large compressive deformation. Int J Mech Sci 145:96–105. https://doi.org/10.1016/j.ijmecsci.2018.06.040

Ingrole A, Hao A, Liang R (2017) Design and modeling of auxetic and hybrid honeycomb structures for in-plane property enhancement. Mater Des 117:72–83. https://doi.org/10.1016/J.MATDES.2016.12.067

Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos Part B Eng 143:172–196. https://doi.org/10.1016/J.COMPOSITESB.2018.02.012

Wang XT, Wang B, Wen ZH, Ma L (2018) Fabrication and mechanical properties of CFRP composite three-dimensional double-arrow-head auxetic structures. Compos Sci Technol 164:92–102. https://doi.org/10.1016/j.compscitech.2018.05.014

Wu W, Hu W, Qian G, Liao H, Xu X, Berto F (2019) Mechanical design and multifunctional applications of chiral mechanical metamaterials: a review. Mater Des 180:107950. https://doi.org/10.1016/j.matdes.2019.107950

de Castro BD, Magalhães F de C, Panzera TH, Campos Rubio JC (2021) An assessment of fully integrated polymer sandwich structures designed by additive manufacturing. J Mater Eng Perform 2021. https://doi.org/10.1007/s11665-021-05604-8

Wang S, Wang J, Xu Y, Zhang W, Zhu J (2020) Compressive behavior and energy absorption of polymeric lattice structures made by additive manufacturing. Front Mech Eng 15:319–327. https://doi.org/10.1007/s11465-019-0549-7

Qi C, Remennikov A, Pei L-Z, Yang S, Yu Z-H, Ngo TD (2017) Impact and close-in blast response of auxetic honeycomb-cored sandwich panels: experimental tests and numerical simulations. Compos Struct 180:161–178. https://doi.org/10.1016/J.COMPSTRUCT.2017.08.020

Li D, Yin J, Dong L, Lakes RS (2018) Strong re-entrant cellular structures with negative Poisson’s ratio. J Mater Sci 53:3493–3499. https://doi.org/10.1007/s10853-017-1809-8

Beharic A, Rodriguez Egui R, Yang L, Egui RR, Yang L (2018) Drop-weight impact characteristics of additively manufactured sandwich structures with different cellular designs. Mater Des 145:122–134. https://doi.org/10.1016/j.matdes.2018.02.066

Yazdani Sarvestani H, Akbarzadeh AH, Niknam H, Hermenean K (2018) 3D printed architected polymeric sandwich panels: energy absorption and structural performance. Compos Struct 200:886–909. https://doi.org/10.1016/J.COMPSTRUCT.2018.04.002

Usta F, Türkmen HS, Scarpa F (2021) Thin-walled structures low-velocity impact resistance of composite sandwich panels with various types of auxetic and non-auxetic core structures. Thin-Walled Struct 163:107738. https://doi.org/10.1016/j.tws.2021.107738

Novak N, Starčevič L, Vesenjak M, Ren Z (2019) Blast response study of the sandwich composite panels with 3D chiral auxetic core. Compos Struct 210:167–178. https://doi.org/10.1016/j.compstruct.2018.11.050

Bronder S, Adorna M, Fíla T, Koudelka P, Falta J, Jiroušek O et al (2021) Hybrid auxetic structures: structural optimization and mechanical characterization. Adv Eng Mater 23:2001393. https://doi.org/10.1002/adem.202001393

Vyavahare S, Kumar S (2021) Numerical and experimental investigation of FDM fabricated re-entrant auxetic structures of ABS and PLA materials under compressive loading. Rapid Prototyp J 27:223–244. https://doi.org/10.1108/RPJ-10-2019-0271

Qiang GC, Wang L, Gao Q (2019) Dynamic crushing behaviors of four kinds of auxetic structures. WCX SAE World Congr Exp SAE International. https://doi.org/10.4271/2019-01-1096

Kuşkun T, Smardzewski J, Kasal A (2021) Experimental and numerical analysis of mounting force of auxetic dowels for furniture joints. Eng Struct 226:111351. https://doi.org/10.1016/j.engstruct.2020.111351

Spahic M, Di Cesare N, Le Duigou A, Keryvin V (2021) Multi-scale analysis of the flexural behaviour of 3D printed cellular polymer materials: comparison between morphing and sandwich beams. Compos Struct 273:114249. https://doi.org/10.1016/j.compstruct.2021.114249

Jin X, Wang Z, Ning J, Xiao G, Liu E, Shu X (2016) Dynamic response of sandwich structures with graded auxetic honeycomb cores under blast loading. Compos Part B Eng 106:206–217. https://doi.org/10.1016/J.COMPOSITESB.2016.09.037

Yang C, Vora HD, Chang Y (2018) Behavior of auxetic structures under compression and impact forces. Smart Mater Struct 27:25012. https://doi.org/10.1088/1361-665x/aaa3cf

Xue Y, Wang W, Han F (2019) Enhanced compressive mechanical properties of aluminum based auxetic lattice structures filled with polymers. Compos Part B Eng 171:183–191. https://doi.org/10.1016/J.COMPOSITESB.2019.05.002

Imbalzano G, Tran P, Ngo TD, Lee PVS (2017) Three-dimensional modelling of auxetic sandwich panels for localised impact resistance. J Sandw Struct Mater 19. https://doi.org/10.1177/1099636215618539

Hernandez R, Slaughter D, Whaley D, Tate J, Asiabanpour B (2016) Analyzing the tensile, compressive, and flexural properties of 3D printed ABS P430 plastic based on printing orientation using fused deposition modeling. Proc 26th Annu Int Solid Free Fabr Symp 939–50

Gibson LJ, Ashby MF, Schajer GS, Robertson CI (1982) The mechanics of two-dimensional cellular materials. Proc R Soc Lond A Math Phys Sci 382:25–42

Kamran M, Xue P, Ahmed N, Zahran MS, Hanif AAG (2017) Axial crushing of uni-sectional bi-tubular inner tubes with multiple outer cross-sections. Lat Am J Solids Struct 14:2198–2220. https://doi.org/10.1590/1679-78254175

Graciano C, Borges H, Martínez G, Teixeira P (2017) Axial crushing of concentric expanded metal tubes under impact loading. Lat Am J Solids Struct 14:874–885. https://doi.org/10.1590/1679-78253670

Author information

Authors and Affiliations

Contributions

Conceptualization: Milad Najafi, Hamed Ahmadi, GholamHossein Liaghat; methodology: Milad Najafi, Hamed Ahmadi, GholamHossein Liaghat; formal analysis and investigation: Milad Najafi, Hamed Ahmadi; writing—original draft preparation: Milad Najafi; writing—review and editing: Hamed Ahmadi; Supervision: Hamed Ahmadi; advision: GholamHossein Liaghat.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Najafi, M., Ahmadi, H. & Liaghat, G. Evaluation of the mechanical properties of fully integrated 3D printed polymeric sandwich structures with auxetic cores: experimental and numerical assessment. Int J Adv Manuf Technol 122, 4079–4098 (2022). https://doi.org/10.1007/s00170-022-10147-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-10147-w