Abstract

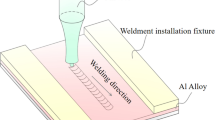

In this research, friction stir joining of aluminum-polypropylene/talc composite was investigated due to the numerous applications of aluminum-polymer joints in automotive and aerospace industry. A novel tool design, including a rotary/stationary holder, was used to improve the appearance and mechanical performance of friction stir lap joints by preventing the mixed molten polymer and aluminum particles from exiting the stirred zone. Effect of tool transverse speed on the joint microstructure and strength was investigated. Using the rotary/stationary holder, tensile-shear strength of the joints increased (by ~ 45 to ~ 220% at various transverse speeds). Since during the tensile-shear test all joints failed from the aluminum/stirred zone interface, joint strength was affected by the formation of anchor-like aluminum pieces in the composite substrate as the mechanical locks, reaction layer at the joint interface, and large voids near the aluminum/stirred zone interface. Joining at the optimum transverse speed led to the highest tensile-shear peak load of 315 N.

Similar content being viewed by others

Availability of data and material

Data will be made available upon reasonable request.

Code availability

Not applicable.

References

Huang Y, Meng X, Xie Y et al (2018) Friction stir welding/processing of polymers and polymer matrix composites. Compos A Appl Sci Manuf 105:235–257. https://doi.org/10.1016/J.COMPOSITESA.2017.12.005

Jiang B, Chen Q, Yang J (2020) Advances in joining technology of carbon fiber-reinforced thermoplastic composite materials and aluminum alloys. Int J Adv Manuf Technol 110:2631–2649. https://doi.org/10.1007/S00170-020-06021-2

Haghshenas M, Khodabakhshi F (2019) Dissimilar friction-stir welding of aluminum and polymer: a review. Int J Adv Manuf Technol 104:333–358. https://doi.org/10.1007/S00170-019-03880-2

Lambiase F, Paoletti A, Durante M (2021) Mechanism of bonding of AA7075 aluminum alloy and CFRP during friction assisted joining. Compos Struct 261:113593. https://doi.org/10.1016/J.COMPSTRUCT.2021.113593

Lambiase F, Paoletti A (2018) Mechanical behavior of AA5053/polyetheretherketone (PEEK) made by friction assisted joining. Compos Struct 189:70–78. https://doi.org/10.1016/J.COMPSTRUCT.2018.01.045

Han SC, Wu LH, Jiang CY et al (2020) Achieving a strong polypropylene/aluminum alloy friction spot joint via a surface laser processing pretreatment. J Mater Sci Technol 50:103–114. https://doi.org/10.1016/j.jmst.2020.02.035

Falck R, Goushegir SM, dos Santos JF, Amancio-Filho ST (2018) AddJoining: a novel additive manufacturing approach for layered metal-polymer hybrid structures. Mater Lett 217:211–214. https://doi.org/10.1016/J.MATLET.2018.01.021

Lambiase F, Grossi V, Paoletti A (2021) Defects formation during friction assisted joining of metals and semi crystalline polymers. J Manuf Process 62:833–844. https://doi.org/10.1016/J.JMAPRO.2020.12.063

Lambiase F, Ko DC (2017) Two-steps clinching of aluminum and carbon fiber reinforced polymer sheets. Compos Struct 164:180–188. https://doi.org/10.1016/J.COMPSTRUCT.2016.12.072

Amancio-Filho ST, dos Santos JF (2009) Joining of polymers and polymer-metal hybrid structures: recent developments and trends. Polym Eng Sci 49:1461–1476. https://doi.org/10.1002/pen.21424

Wang Q, Jia ZY, Zhang BY et al (2021) Influence of processing parameters on joint shear performance in laser direct joining of CFRTP and aluminum alloy. Mater Des 209:109996. https://doi.org/10.1016/J.MATDES.2021.109996

Lambiase F, Genna S (2018) Laser assisted joining of AA5053 aluminum alloy with polyvinyl chloride (PVC). Opt Laser Technol 107:80–88. https://doi.org/10.1016/J.OPTLASTEC.2018.05.023

Lamberti C, Solchenbach T, Plapper P, Possart W (2014) Laser assisted joining of hybrid polyamide-aluminum structures. Phys Procedia 56:845–853. https://doi.org/10.1016/j.phpro.2014.08.103

Genna S, Lambiase F, Leone C (2018) Effect of laser cleaning in laser assisted joining of CFRP and PC sheets. Compos B Eng 145:206–214. https://doi.org/10.1016/J.COMPOSITESB.2018.03.032

Ozlati A, Movahedi M, Tamizi M et al (2019) An alternative additive manufacturing-based joining method to make Metal/Polymer hybrid structures. J Manuf Process 45:217–226. https://doi.org/10.1016/j.jmapro.2019.07.002

Falck R, Dos Santos JF, Amancio-Filho ST (2019) Microstructure and mechanical performance of additively manufactured aluminum 2024–T3, acrylonitrile butadiene styrene hybrid joints using an AddJoining technique. Materials 12:864. https://doi.org/10.3390/MA12060864

Rana PK, Narayanan RG, Kailas SV (2021) Assessing the dwell time effect during friction stir spot welding of aluminum polyethylene multilayer sheets by experiments and numerical simulations. Int J Adv Manuf Technol 114:1953–1973. https://doi.org/10.1007/S00170-021-06910-0

Min J, Li Y, Li J et al (2014) Friction stir blind riveting of carbon fiber-reinforced polymer composite and aluminum alloy sheets. Int J Adv Manuf Technol 76:1403–1410. https://doi.org/10.1007/S00170-014-6364-8

Lambiase F, Grossi V, Paoletti A (2020) Friction stir joining of CFRP laminates with amorphous polymers: Influence of processing speeds. J Manuf Process 55:186–197. https://doi.org/10.1016/J.JMAPRO.2020.03.029

Lambiase F, Grossi V, Paoletti A (2022) High-speed joining of hybrid metal-polymer joints during the friction-assisted joining process. Compos Struct 280:114890. https://doi.org/10.1016/J.COMPSTRUCT.2021.114890

Lambiase F, Paoletti A, Grossi V, di Ilio A (2017) Friction assisted joining of aluminum and PVC sheets. J Manuf Process 29:221–231

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R Rep 50:1–78

Khodabakhshi F, Haghshenas M, Chen J et al (2017) Bonding mechanism and interface characterisation during dissimilar friction stir welding of an aluminium/polymer bi-material joint. Sci Technol Weld Joining 22:182–190. https://doi.org/10.1080/13621718.2016.1211583

Huang Y, Meng X, Wang Y et al (2018) Joining of aluminum alloy and polymer via friction stir lap welding. J Mater Process Technol 257:148–154. https://doi.org/10.1016/J.JMATPROTEC.2018.02.043

Huang Y, Meng X, Xie Y et al (2018) Joining of carbon fiber reinforced thermoplastic and metal via friction stir welding with co-controlling shape and performance. Compos A Appl Sci Manuf 112:328–336. https://doi.org/10.1016/j.compositesa.2018.06.027

Paidar M, Ojo OO, Moghanian A et al (2019) Pre-threaded hole friction stir spot welding of AA2219/PP-C30S sheets. J Mater Process Technol 273:116272. https://doi.org/10.1016/J.JMATPROTEC.2019.116272

Shahmiri H, Movahedi M, Kokabi AH (2017) Friction stir lap joining of aluminium alloy to polypropylene sheets. Sci Technol Weld Joining 22:120–126. https://doi.org/10.1080/13621718.2016.1204171

Karami Pabandi H, Movahedi M, Kokabi AH (2017) A new refill friction spot welding process for aluminum/polymer composite hybrid structures. Compos Struct 174:59–69. https://doi.org/10.1016/J.COMPSTRUCT.2017.04.053

Wu J-H, Chen C-W, Wu Y-T et al (2015) Mechanical properties, morphology, and crystallization behavior of polypropylene/elastomer/talc composites. Polym Compos 36:69–77

Qiu F, Wang M, Hao Y, Guo S (2014) The effect of talc orientation and transcrystallization on mechanical properties and thermal stability of the polypropylene/talc composites. Compos A Appl Sci Manuf 58:7–15. https://doi.org/10.1016/J.COMPOSITESA.2013.11.011

Jahani Y (2011) Comparison of the effect of mica and talc and chemical coupling on the rheology, morphology, and mechanical properties of polypropylene composites. Polym Adv Technol 22:942–950. https://doi.org/10.1002/pat.1600

Shelesh-Nezhad K, Taghizadeh A (2007) Shrinkage behavior and mechanical performances of injection molded polypropylene/talc composites. Polym Eng Sci 47:2124–2128

Meng X, Huang Y, Cao J et al (2021) Recent progress on control strategies for inherent issues in friction stir welding. Prog Mater Sci 115:100706. https://doi.org/10.1016/j.pmatsci.2020.100706

Sauer JA, Pae KD (2003) Structure and thermal behavior of pressure-crystallized polypropylene. J Appl Phys 39:4959. https://doi.org/10.1063/1.1655893

Inácio ALN, Nonato RC, Bonse BC (2018) Mechanical and thermal behavior of aged composites of recycled PP/EPDM/talc reinforced with bamboo fiber. Polym Testing 72:357–363. https://doi.org/10.1016/J.POLYMERTESTING.2018.10.035

Meng X, Huang Y, Xie Y et al (2019) Friction self-riveting welding between polymer matrix composites and metals. Compos A Appl Sci Manuf 127:105624. https://doi.org/10.1016/j.compositesa.2019.105624

Funding

The authors would like to acknowledge the economic support received from the Iran National Science Foundation (Grant No. 97011444).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design, material preparation, data collection and analysis, and manuscript preparation. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shiravi, H., Movahedi, M. & Ozlati, A. Improving appearance and mechanical strength of aluminum-polypropylene/talc composite friction stir joint using a novel tool design. Int J Adv Manuf Technol 121, 3717–3730 (2022). https://doi.org/10.1007/s00170-022-09581-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09581-7