Abstract

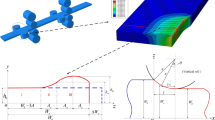

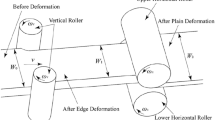

Energy method is an essential theoretical approach to analyze plastic forming, which is widely used in rolling process. An analysis model for vertical rolling process is established according to energy theory. By using global weighted method firstly, the 3D continuous velocity field, strain rate field and the corresponding power functional are proposed. The unknown variables are calculated numerically based on the principle of minimum energy. Then, deformation parameters and rolling force are determined. The analysis on specific examples shows that the theoretical prediction value of weighted model is in good agreement with experimental results. Moreover, the effects of several shape and rolling parameters on rolling force, rolling power and edge deformation are studied. Both the width reduction rate and initial slab thickness have significant influences on dog-bone size and rolling force. A wider slab slightly increases the nonuniformity of dog-bone deformation. And the increase of vertical roller radius can weaken the edge deformation.

Similar content being viewed by others

Availability of data and material

The authors assure the transparency and availability of data and material, and adhere to discipline-specific rules for acquiring, selecting and processing data.

Code availability

The authors make sure we have permissions for the use of software, and the availability of the custom code.

References

Oh SI, Kobayashi S (1975) An approximate method for a three-dimensional analysis of rolling. Int J Mech Sci 17(4):293–305. https://doi.org/10.1016/0020-7403(75)90010-7

Kato K, Murota T, Kumagai T (1980) Flat-rolling of rigid-perfectly plastic solid bar by the energy method. J Jpn Soc Techol Plast 21:359–369

Avitzur B, Pachla W (1986) The upper bound approach to plane strain problems using linear and rotational velocity fields—part I: Basic concepts. J Manuf Sci E-T ASME 108(4):295–306. https://doi.org/10.1115/1.3187080

Avitzur B, Pachla W (1986) The upper bound approach to plane strain problems using linear and rotational velocity fields—part II. J Manuf Sci E-T ASME 108(4):307–316. https://doi.org/10.1115/1.3187080

Avitzur B, Gordon W, Talbert S (1987) Analysis of strip rolling by the upper bound approach. J Manuf Sci E-T ASME 109(4):338–346. https://doi.org/10.1115/1.3187137

Dong YG, Zhang WZ, Song JF (2010) Theoretical and experimental research on rolling force for rail hot rolling by universal mill. ISIJ Int 17(1):27–32. https://doi.org/10.1016/S1006-706X(10)60040-4

Zhang JL, Cui ZS (2011) Prediction of velocity and deformation fields during multipass plate hot rolling by novel mixed analytical-numerical method. ISIJ Int 18(7):20–27. https://doi.org/10.1016/S1006-706X(11)60085-X

Sun J, Liu YM, Hu YK, Wang QL, Zhang DH, Zhao DW (2016) Application of hyperbolic sine velocity field for the analysis of tandem cold rolling. Int J Mech Sci 108–109:166–173. https://doi.org/10.1016/j.ijmecsci.2016.02.004

Zhang DH, Cao JZ, Xu JJ, Peng W, Zhao DW (2014) Simplified weighted velocity field for prediction of hot strip rolling force by taking into account flattening of rolls. ISIJ Int 21(7):637–643. https://doi.org/10.1016/S1006-706X(14)60099-6

Cao JZ, Zhao DW, Zhang SH, Peng W, Chen SZ, Zhang DH (2014) Analysis of hot tandem rolling force with logarithmic velocity field and ea yield criterion. ISIJ Int 21(3):295–299. https://doi.org/10.1016/S1006-706X(14)60045-5

Zhang SH, Song BN, Wang XN, Zhao DW (2014) Analysis of plate rolling by MY criterion and global weighted velocity field. Appl Math Model 38(14):3485–3494. https://doi.org/10.1016/j.apm.2013.11.061

Ma GS, Liu YM, Peng W, Yin FC, Ding JG, Zhao DW, Di HS, Zhang DH (2017) A new model for thermo-mechanical coupled analysis of hot rolling. J Braz Soc Mech Sci Eng 39(2):523–530. https://doi.org/10.1007/s40430-015-0390-9

Peng W, Ding JG, Zhang DH, Zhao DW (2017) A novel approach for the rolling force calculation of cold rolled sheet. J Braz Soc Mech Sci Eng 39(10):1–11. https://doi.org/10.1007/s40430-017-0774-0

Peng W, Zhang DH, Zhao DW (2017) Application of parabolic velocity field for the deformation analysis in hot tandem rolling. Int J Adv Manuf Technol 91:2233–2243. https://doi.org/10.1007/s00170-016-9936-y

Li S, Wang ZG, Guo YF (2019) A novel analytical model for prediction of rolling force in hot strip rolling based on tangent velocity field and MY criterion. J Manuf Process 47:202–210. https://doi.org/10.1016/j.jmapro.2019.09.037

Yun D, Lee D, Kim J, Hwang S (2012) A new model for the prediction of the dog bone shape in steel mills. ISIJ Int 52(6):1109–1117. https://doi.org/10.2355/isijinternational.52.1109

Li X, Wang HY, Liu YM, Zhang DH, Zhao DW (2016) Analysis of edge rolling based on continuous symmetric parabola curves. J Braz Soc Mech Sci Eng 39(4):1–10. https://doi.org/10.1007/s40430-016-0587-6

Liu YM, Ma GS, Zhang DH, Zhao DW (2015) Upper bound analysis of rolling force and dog-bone shape via sine function model in vertical rolling. J Mater Process Tech 223:91–97. https://doi.org/10.1016/j.jmatprotec.2015.03.051

Liu YM, Zhang DH, Zhao DW, Sun J (2016) Analysis of vertical rolling using double parabolic model and stream function velocity field. Int J Adv Manuf Technol 82(5–8):1153–1161. https://doi.org/10.1007/s00170-015-7393-7

Liu YM, Sun J, Zhang DH, Zhao DW (2018) Three-dimensional analysis of edge rolling based on dual-stream function velocity field theory. J Manuf Process 34:349–355. https://doi.org/10.1016/j.jmapro.2018.06.012

Liu YM, Wang T, Wang ZH, Hao PJ, He DP (2020) Research on mechanics parameters of edge rolling based on dual-stream function. J Plast Eng 27(08):172–178. https://doi.org/10.3969/j.issn.1007-2012.2020.08.023

Liu YM, Hao PJ, Wang T, Ren ZK, Zhang SH (2020) Mathematical model for vertical rolling deformation based on energy method. Int J Adv Manuf Technol 107:875–883. https://doi.org/10.1007/s00170-020-05094-3

Yu MH (1983) Twin shear stress yield criterion. Int J Mech Sci 25(1):71–74. https://doi.org/10.1016/0020-7403(83)90088-7

Huang WB, Zeng GP (1989) Application of twin shear stress yield criterion to solve some problems in plastic mechanics. ACTA Mech Sinica-PRC 21(2):249–256. https://doi.org/10.6052/0459-1879-1989-2-1989-302

Zhang SH (2016) Mechanical principle of plastic forming. Metallurgical Industry Press, Beijing

Zhang SH, Zhao DW, Gao CR (2012) The calculation of roll torque and roll separating force for broadside rolling by stream function method. Int J Mech Sci 57(1):74–78. https://doi.org/10.1016/j.ijmecsci.2012.02.006

Zhao ZY (1980) Metal plastic deformation and rolling theory. Metallurgical Industry Press, Beijing

Shibahara T, Misaka Y, Kono T, Koriki M, Takemoto H (1981) Edger set-up model at roughing train in a hot strip mill. Tetsu-to-Hagane 67(15):2509–2151

Xiong SW, Zhu XL, Liu XH, Wang G, Zhang Q, Li H, Meng X, Han L (1997) Mathematical model of width reduction process of roughing trains of hot strip mills. Shanghai Metal 19(1):39–43

Okado M, Ariizumi T, Noma Y, Yabuuchi K, Yamazaki Y (1981) Width behaviour of the head and tail of slabs in edge rolling in hot strip mills. Tetsu-to-Hagane 67(15):2516–2525

Xiong SW, Liu XH, Wang GD, Zhang W (1997) Simulation of vertical-horizontal rolling process during width reduction by full three-dimensional rigid-plastic finite element method. J Mater Eng Perform 6(6):757–765. https://doi.org/10.1007/s11665-997-0078-0

Funding

The authors declare that no funds, grants or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Boxin Yang. The first draft of the manuscript was written by Boxin Yang and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

The authors declare that the submitted work is original. Neither the entire paper nor any part of its content has been published or has been accepted elsewhere. It is not being submitted to any other journal.

Consent to participate

The authors confirm that this research does not involve Human Participants and/or Animals.

Consent for publication

The authors consent for publication in The International Journal of Advanced Manufacturing Technology exclusively.

Conflicts of interest/competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, B., Xu, H. & An, Q. Analysis of 3D plastic deformation in vertical rolling based on global weighted velocity field. Int J Adv Manuf Technol 120, 6647–6659 (2022). https://doi.org/10.1007/s00170-022-09190-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09190-4