Abstract

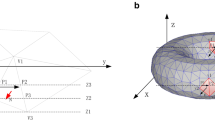

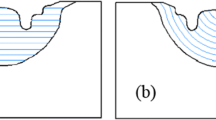

Wire and arc additive remanufacturing (WAAR) technology has become a new solution for hot forging dies repair and remanufacturing. In this study, a path generation method is proposed for WAAR of hot forging dies. At first, a WAAR process of the hot forging die is presented, and considering the characteristics of large welding heat input and complex 3D digital model, the hybrid path planning strategy is confirmed as an appropriate strategy for WAAR. The developed hybrid path generation method for WAAR consists of three main steps: determine the direction of the scan line; divide and fill the internal area; and connect the sub-paths. The relatively optimal scanning direction is determined by calculating the length and inclination angle of each line segment in the contour lines, which reduces the possibility of sharp angles. The internal region is divided according to the position of the selected extreme points, and the path space is adjusted to avoid the occurrence of the unfilled phenomenon. At the stage of sub-path connection, some criteria are proposed to reduce the number of sub-paths. At last, the effectiveness and robustness of the proposed method are validated through the planar deposition experiment and the WAAR process of four damaged hot forging dies.

Similar content being viewed by others

Availability of data and material

Not applicable.

References

Debroy T, Wei H, Zuback JS, Mukherjee T, Elmer JW, Milewski JO, Beese AM, Wilson-Heid A, De A, Zhang W (2018) Additive manufacturing of metallic components – process, structure and properties. Prog Mater Sci 92:112–224

Lewandowski JJ, Seifi M (2016) Metal additive manufacturing: a review of mechanical properties. Annu Rev Mater Res 46:151–186

Tapia G, Elwany A (2014) A review on process monitoring and control in metal-based additive manufacturing. J Manuf Sci Eng 136(6):060801

Herzog D, Seyda V, Wycisk E, Emmelmann C (2016) Additive manufacturing of metals. Acta Mater 117:371–392

Karayel E, Bozkurt Y (2020) Additive manufacturing method and different welding applications. J Mater Res Technol 9(5):11424–11438

Mehnen J, Ding J, Lockett H, Kazanas P (2014) Design study for wire and arc additive manufacture. Int J Prod Dev 19(1/2/3):2–20

Wang F, Williams S, Colegrove P, Antonysamy AA (2013) Microstructure and mechanical properties of wire and arc additive manufactured Ti-6Al-4V. Metall Mater Trans A 44(2):968–977

Xiong J, Lei Y, Chen H, Zhang G (2016) Fabrication of inclined thin-walled parts in multi-layer single-pass GMAW-based additive manufacturing with flat position deposition. J Mater Process Technol 240:397–403

Williams SW, Martina F, Addison AC, Ding J, Pardal G, Colegrove P (2016) Wire + arc additive manufacturing. Mater Sci Technol 32(7):641–647

Li Y, Han Q, Zhang G, Horváth I (2018) A layers-overlapping strategy for robotic wire and arc additive manufacturing of multi-layer multi-bead components with homogeneous layers. Int J Adv Manuf Technol 96(9-12):3331–3344

Ding D, Shen C, Pan Z, Cuiuri D, Li H, Larkin N, Duin SV (2016) Towards an automated robotic arc-welding-based additive manufacturing system from CAD to finished part. Comput Aided Des 73:66–75

Ding D, Pan Z, Cuiuri D, Li H (2015) A practical path planning methodology for wire and arc additive manufacturing of thin-walled structures. Robot Comput Integr Manuf 34:8–19

Zhang Y, Chen Y, Li P, Male AT (2003) Weld deposition-based rapid prototyping: a preliminary study. J Mater Process Technol 135(2):347–357

Ding D, Pan Z, Cuiuri D, Li H (2014) A tool-path generation strategy for wire and arc additive manufacturing. Int J Adv Manuf Technol 73(1-4):173–183

Dwivedi R, Kovacevic R (2004) Automated torch path planning using polygon subdivision for solid freeform fabrication based on welding. J Manuf Syst 23(4):278–291

Venturini G, Montevecchi F, Scippa A, Campatelli G (2016) Optimization of WAAM deposition patterns for T-crossing features. Proc CIRP 55:95–100

Michel F, Lockett H, Ding J, Martina F, Marinelli G, Williams S (2019) A modular path planning solution for wire + arc additive manufacturing. Robot Comput Integr Manuf 60:1–11

Chen C, Wang Y, Ou H, He Y, Tang X (2014) A review on remanufacture of dies and moulds. J Clean Prod 64:13–23

Jhavar S, Paul CP, Jain NK (2013) Causes of failure and repairing options for dies and molds: a review. Eng Fail Anal 34:519–535

Liu D, Liu R, Wei H, Pan P (2013) Influence of carbon content on shock hardening behavior of cobalt-base hardfacing deposits. Mater Manuf Process 28(6):643–649

Jin Y, He Y, Xue G, Fu J (2015) A parallel-based path generation method for fused deposition modeling. Int J Adv Manuf Technol 77(5-8):927–937

Jin Y, He Y, Fu J, Gan W, Lin Z (2014) Optimization of tool-path generation for material extrusion-based additive manufacturing technology. Addit Manuf 1-4:32–47

Funding

The authors gratefully acknowledge a Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Contributions

Yonghua Shen: conceptualization, experiments, and writing; Yanhong Wei: conceptualization, writing, and editing; Renpei Liu: conceptualization and project supervision.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shen, Y., Wei, Y. & Liu, R. A path generation method for wire and arc additive remanufacturing of complex hot forging dies. Int J Adv Manuf Technol 117, 1935–1943 (2021). https://doi.org/10.1007/s00170-021-07813-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07813-w