Abstract

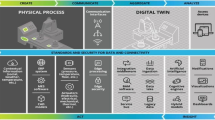

This work explores the improvement of operational decision-making in a Fast Fashion manufacturing company, considering the Industry 4.0 era. The segment requires agile and flexible decision-making techniques to guarantee the companies survival in a high variety environment of products and demand. The proposed approach was based on three stages. First, we suggested changes and improvements in the system to adapt it to the Industry 4.0 principles. Then, we proposed a Digital Twin (DT) focused on operational resource planning (physical and human). The DT was composed of a Discrete Event Simulation model, an Artificial Intelligence model, and a decision dashboard that provides a user-friendly interface for the decision-maker. Finally, the last stage corresponds to cyclical and constant DT-based decision-making. The DT-based decisions helped to decrease the number of operators in the line reducing their idleness and, at the same time, the total lead time became shorter. Therefore, we highlight that the concepts and solutions of Industry 4.0 might be consistent with small companies without major structural changes, contributing to the evolution of the manufacturing systems.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Watson MZ, Yan R-N (2013) An exploratory study of the decision processes of fast versus slow fashion consumers. J Fash Mark Manag 17:141–159. https://doi.org/10.1108/JFMM-02-2011-0045

Mehrjoo M, Pasek ZJ (2015) Risk assessment for the supply chain of fast fashion apparel industry: a system dynamics framework. Int J Prod Res 54:28–48. https://doi.org/10.1080/00207543.2014.997405

Fares N, Lebbar M, Sbihi N (2018) Quick response in fast fashion retail: an optimization supply chain responsiveness model. In: Proceedings of the 2018 International Conference on Optimization and Applications. ICOA 2018, Mohammedia, pp 1–5

Caro F, Gallien J (2012) Clearance pricing optimization for a fast-fashion retailer. Oper Res 60:1404–1422. https://doi.org/10.1287/opre.1120.1102

Al-Zubaidi H, Tyler D (2004) A simulation model of quick response replenishment of seasonal clothing. Int J Retail Distrib Manag 32:320–327. https://doi.org/10.1108/09590550410538024

Sardar S, Lee YH, Memon MS (2016) Multi-objective outsourcing strategies for functional and fast fashion products in textile supply chain. Int J Eng Technol 8:870–886

Wan J, Cai H, Zhou K (2015) Industrie 4.0: enabling technologies. In: Proceedings of 2015 International Conference on Intelligent Computing and Internet of Things. ICIT 2015, Harbin, pp 135–140

Da Xu L, Xu EL, Li L (2018) Industry 4.0: state of the art and future trends. Int J Prod Res 56:2941–2962. https://doi.org/10.1080/00207543.2018.1444806

Tao F, Cheng J, Qi Q, Zhang M, Zhang H, Sui F (2018) Digital twin-driven product design, manufacturing and service with big data. Int J Adv Manuf Technol 94:3563–3576. https://doi.org/10.1007/s00170-017-0233-1

Tao F, Zhang M (2017) Digital Twin Shop-Floor : A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 5:20418–20427. https://doi.org/10.1109/ACCESS.2017.2756069

Cachon GP, Swinney R (2011) The value of fast fashion: quick response, enhanced design, and strategic consumer behavior. Manag Sci 57:778–795. https://doi.org/10.1287/mnsc.1100.1303

Passariello C (2008) Logistics Are in Vogue With Designers. In: Wall Str. J. https://www.wsj.com/articles/SB121451654414108561. Accessed 3 Jan 2021

Rohwedder C, Johnson K (2008) Pace-Setting Zara Seeks More Speed To Fight Its Rising Cheap-Chic Rivals. In: Wall Str. J. https://www.wsj.com/articles/SB120345929019578183#:~:text=Permalink-,Pace-Setting Zara Seeks More Speed To,Its Rising Cheap-Chic Rivals&text=ARTEIXO%2C Spain -- Zara stores,As rivals catch up%2C Mr. Accessed 3 Jan 2021

SEBRAE (2014) FAST FASHION NO VAREJO. In: SEBRAE. http://www.bibliotecas.sebrae.com.br/chronus/ARQUIVOS_CHRONUS/bds/bds.nsf/84f335cf0a92c75d356512b9ec15f0ec/$File/2014_08_22_RT_Julho_Varejo_FastFashion_pdf.pdf. Accessed 16 Apr 2021

Bonilla MDR, del Olmo Arriaga JL, Andreu D (2019) The interaction of Instagram followers in the fast fashion sector: the case of Hennes and Mauritz (H&M). J Glob Fash Market 10:342–357. https://doi.org/10.1080/20932685.2019.1649168

Majeed MAA, Rupasinghe TD (2017) Internet of things (IoT) embedded future supply chains for industry 4.0: an assessment from an ERP-based fashion apparel and footwear industry. Int J Supply Chain Manag 6:25–40

Nicoletti L, Padovano A (2019) Human factors in occupational health and safety 4.0: a cross-sectional correlation study of workload, stress and outcomes of an industrial emergency response. Int J Simul Process Model 14:178–195. https://doi.org/10.1504/IJSPM.2019.099912

Winkelhaus S, Grosse EH (2020) Logistics 4.0: a systematic review towards a new logistics system. Int J Prod Res 58:18–43. https://doi.org/10.1080/00207543.2019.1612964

Princes E (2020) Facing disruptive challenges in supply chain 4.0. Int J Supply Chain Manag 9:52–57

Sony M (2018) Industry 4.0 and lean management: a proposed integration model and research propositions. Prod Manuf Res 6:416–432. https://doi.org/10.1080/21693277.2018.1540949

Sanders A, Elangeswaran C, Wulfsberg J (2016) Industry 4 . 0 Implies Lean Manufacturing : Research Activities in Industry 4 . 0 Function as Enablers for Lean Manufacturing. J Ind Eng Manag 9:811–833. https://doi.org/10.3926/jiem.194

Zhong RY, Xu X, Klotz E, Newman ST (2017) Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 3:616–630. https://doi.org/10.1016/J.ENG.2017.05.015

Moeuf A, Pellerin R, Lamouri S, Tamayo-Giraldo S, Barbaray R (2018) The industrial management of SMEs in the era of Industry 4.0. Int J Prod Res 56:1118–1136. https://doi.org/10.1080/00207543.2017.1372647

Longo F, Nicoletti L, Padovano A (2017) Smart operators in industry 4.0: a human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Comput Ind Eng 113:144–159. https://doi.org/10.1016/j.cie.2017.09.016

Alfieri A, De Marco A, Pastore E (2019) Last mile logistics in Fast Fashion supply chains: a case study. IFAC-PapersOnLine 52:1693–1698. https://doi.org/10.1016/j.ifacol.2019.11.444

Backs S, Jahnke H, Lüpke L, Stücken M, Stummer C (2020) Traditional versus fast fashion supply chains in the apparel industry : an agent-based simulation approach. Ann Oper Res XX:1–27. https://doi.org/10.1007/s10479-020-03703-8

Cagliano AC, Demarco A, Rafele C, Volpe S (2011) Using system dynamics in warehouse management : a fast-fashion case study. J Manuf Technol Manag 22:171–188. https://doi.org/10.1108/17410381111102207

Fares N, Lebbar M, Sbihi N, Mamoun AEBE (2018) Data Mining Dynamic Hybrid Model for Logistic Supplying Chain : Assortment Setting in Fast Fashion Retail. In: Proceedings of the 2018 Advanced Intelligent Systems for Sustainable Development, pp 1–7. https://doi.org/10.1007/978-3-030-11928-7

Fares N, Lebbar M, Sbihi N (2018) A Customer Profiling’ Machine Learning Approach, for In-store Sales in Fast Fashion. In: Proceedings of the 2018 Advanced Intelligent Systems for Sustainable Development, pp 1–6. https://doi.org/10.1007/978-3-030-11928-7

Kaczorowska-Spychalska D (2018) Shaping consumer behaviour in the fashion industry by interactive communication forms. Fibres Text East Eur 26:13–19. https://doi.org/10.5604/01.3001.0012.1307

Kotouza MT, Tsarouchis S, Kyprianidis A et al (2020) Towards Fashion Recommendation: an AI System for Clothing Data Retrieval and Analysis. In: Proceedings of the 2020 International Conference on Artificial Intelligence Applications and Innovations, pp 1–12. https://doi.org/10.1007/978-3-030-49186-4

Kumar P, Ashok D (2018) Artificial neural network based geometric error correction model for enhancing positioning accuracy of a robotic sewing manipulator. Procedia Comput Sci 133:1048–1055. https://doi.org/10.1016/j.procs.2018.07.069

Lee S, Lim Y, Lee W et al (2020) A Store Management System for the Improvement of Shopping Process of Omni-shoppers of Fast Fashion Brand. In: Proceedings of the 2020 International Conference on E-Business and Applications, pp 138–144. https://doi.org/10.1145/3387263.3387280

Papachristou E, Chrysopoulos A, Bilalis N (2020) Machine learning for clothing manufacture as a mean to respond quicker and better to the demands of clothing brands : a Greek case study. Int J Adv Manuf Technol:1–12. https://doi.org/10.1007/s00170-020-06157-1

See-to EWK, Ngai EWT (2018) Customer reviews for demand distribution and sales nowcasting: a big data approach. Ann Oper Res 270:415–431. https://doi.org/10.1007/s10479-016-2296-z

dos Santos CH, De Queiroz JA, Leal F, Montevechi JAB (2020) Use of simulation in the industry 4.0 context : creation of a Digital Twin to optimise decision making on non-automated process. J Simul 14:1–14. https://doi.org/10.1080/17477778.2020.1811172

Shafto M, Conroy M, Doyle R et al (2010) DRAFT Modeling , Simulation, Information Technology & Processing Roadmap. In: Technology Area 11 - National Aeronautics and Space Administration (NASA), pp 1–27

Zhuang C, Liu J, Xiong H (2018) Digital twin-based smart production management and control framework for the complex product assembly shop-floor. Int J Adv Manuf Technol 96:1149–1163. https://doi.org/10.1007/s00170-018-1617-6

Yildiz E, Møller C, Bilberg A (2021) Demonstration and evaluation of a digital twin-based virtual factory. Int J Adv Manuf Technol 114:185–203. https://doi.org/10.1007/s00170-021-06825-w

dos Santos CH, Montevechi JAB, de Queiroz JA, de Carvalho Miranda R, Leal F (2021) Decision support in productive processes through DES and ABS in the Digital Twin era : a systematic literature review. Int J Prod Res 59:1–20. https://doi.org/10.1080/00207543.2021.1898691

Avci O, Abdeljaber O, Kiranyaz S, Hussein M, Gabbouj M, Inman DJ (2021) A review of vibration-based damage detection in civil structures: from traditional methods to Machine Learning and Deep Learning applications. Mech Syst Signal Process 147:1–45. https://doi.org/10.1016/j.ymssp.2020.107077

Shi Z, Yao W, Li Z, Zeng L, Zhao Y, Zhang R, Tang Y, Wen J (2020) Artificial intelligence techniques for stability analysis and control in smart grids: methodologies, applications, challenges and future directions. Appl Energy 278:1–25. https://doi.org/10.1016/j.apenergy.2020.115733

Russels S, Norvig P (2020) Artificial Intelligence: a Modern Approach, 4th edn. Pearson

Lee J, Davari H, Singh J, Pandhare V (2018) Industrial Artificial Intelligence for industry 4.0-based manufacturing systems. Manuf Lett 18:20–23. https://doi.org/10.1016/j.mfglet.2018.09.002

Raschka S, Julian D, Hearty J (2016) Python: Deeper Insights into Machine Learning: Leverage benefits of machine learning techniques using Python, 1st edn. Packt Publishing

Altan A, Karasu S (2019) The effect of kernel values in support vector machine to forecasting performance of financial time series and cognitive decision making. J Cogn Syst 4:17–21

Lall U, Moon Y, Kwon H, Bosworth K (2006) Locally weighted polynomial regression : parameter choice and application to forecasts of the Great Salt Lake. Water Resour Res 42:1–11. https://doi.org/10.1029/2004WR003782

Liu C, Hu Z, Li Y, Liu S (2017) Forecasting copper prices by decision tree learning. Res Policy 52:427–434. https://doi.org/10.1016/j.resourpol.2017.05.007

Mishra N, Soni HK, Sharma S, Upadhyay AK (2018) Development and analysis of Artificial Neural Network models for rainfall prediction by using time-series data. Int J Intell Syst Appl 10:16–23. https://doi.org/10.5815/ijisa.2018.01.03

Khorram M, Faria P, Abrishambaf O et al (2019) CO2 Concentration Forecasting in an Office Using Artificial Neural Network. In: Proceeding of the 2019 International Conference on Intelligent System Application to Power Systems, pp 1–6. https://doi.org/10.1109/ISAP48318.2019.9065944

Dey A (2016) Machine Learning Algorithms: a Review. Int J Comput Sci Inf Technol 7:1174–1179

Choi TM, Hui CL, Liu N, Ng SF, Yu Y (2014) Fast fashion sales forecasting with limited data and time. Decis Support Syst 59:84–92. https://doi.org/10.1016/j.dss.2013.10.008

Loureiro ALD, Miguéis VL, da Silva LFM (2018) Exploring the use of deep neural networks for sales forecasting in fashion retail. Decis Support Syst 114:81–93. https://doi.org/10.1016/j.dss.2018.08.010

Liu P, Ming W, Hu B (2020) Sales forecasting in rapid market changes using a minimum description length neural network. Neural Comput Applic 8:1–12. https://doi.org/10.1007/s00521-020-05294-8

Buer S, Strandhagen JO, Chan FTS (2018) The link between Industry 4.0 and lean manufacturing : mapping current research and establishing a research agenda. Int J Prod Res 7543:1–17. https://doi.org/10.1080/00207543.2018.1442945

Tortorella GL, Fettermann D (2018) Implementation of industry 4.0 and lean production in brazilian manufacturing companies. Int J Prod Res 56:2975–2987. https://doi.org/10.1080/00207543.2017.1391420

Montevechi JAB, Santos CH, Gabriel GT et al (2020) A Method Proposal for Conducting Simulation Projects in Industry 4.0: a Cyber-Physical System in an Aeronautical Industry. In: Proceeding of the 2020 Winter Simulation Conference. Orlando, USA, pp 2731–2742. https://doi.org/10.1109/WSC48552.2020.9384041

Gabriel GT, Campos AT, Leal F, Montevechi JAB (2020) Good practices and deficiencies in conceptual modelling: a systematic literature review. J Simul XX:1–17. https://doi.org/10.1080/17477778.2020.1764875

Sargent RG (2013) Verification and validation of simulation models. J Simul 7:12–24. https://doi.org/10.1057/jos.2012.20

Ren S, Chan HL, Ram P (2017) A Comparative Study on Fashion Demand Forecasting Models with Multiple Sources of Uncertainty. Ann Oper Res 257:335–355. https://doi.org/10.1007/s10479-016-2204-6

Riedmiller M (1994) Advanced supervised learning in multi-layer perceptrons - From backpropagation to adaptive learning algorithms. Comput Stand Inter 16:265–278. https://doi.org/10.1016/0920-5489(94)90017-5

Braga PL, Oliveira ALI, Meira SRL (2007) Software Effort Estimation using Machine Learning Techniques with Robust Confidence Intervals. In: Proceeding of the 2007 International Conference on Hybrid Intelligent Systems Software, pp 352–357. https://doi.org/10.1109/his.2007.56

Chai T, Draxler RR (2014) Root mean square error (RMSE) or mean absolute error (MAE)? -Arguments against avoiding RMSE in the literature. Geosci Model Dev 7:1247–1250. https://doi.org/10.5194/gmd-7-1247-2014

Wright L, Davidson S (2020) How to tell the difference between a model and a digital twin. Adv Model Simul Eng Sci 7:1–13. https://doi.org/10.1186/s40323-020-00147-4

dos Santos CH, Lima RDC, Leal F et al (2020) A decision support tool for operational planning : a Digital Twin using simulation and forecasting methods. Production 30:1–17. https://doi.org/10.1590/0103-6513.20200018

Alam KM, EL Saddik A (2017) C2PS : a Digital Twin Architecture Reference Model for the Cloud-Based Cyber-Physical Systems. IEEE Access 5:2050–2062. https://doi.org/10.1109/ACCESS.2017.2657006

Acknowledgements

The authors would like to express their gratitude to CNPq, CAPES, and FAPEMIG.

Funding

This work was funding by the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), and Fundação de Amparo à Pesquisa do Estado de Minas Gerais (FAPEMIG).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

Not applicable.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

dos Santos, C.H., Gabriel, G.T., do Amaral, J.V.S. et al. Decision-making in a fast fashion company in the Industry 4.0 era: a Digital Twin proposal to support operational planning. Int J Adv Manuf Technol 116, 1653–1666 (2021). https://doi.org/10.1007/s00170-021-07543-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07543-z