Abstract

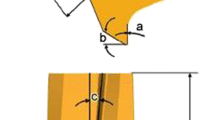

The recent developments in science and technology lead to the miniaturization of components in fields like aerospace, biomedical, and electronics. Due to the small tool dimensions and premature tool failure, the tool wear behavior is complicated in micro endmilling of difficult-to-cut materials. In this work, the influence of size effect on wear behavior of AlTiN-coated WC micro endmill and its effects on surface roughness, burr formation, and chip formation during machining on Inconel 718 was studied. It was found that adhesion, delamination, chipping, cutting edge rounding, and flank wear are the significant wear behaviors on AlTiN-coated WC micro endmill during machining of Inconel 718. Workpiece adhesion was observed to be severe in the plowing dominant region. The tool life with 6-μm feed/tooth was found to be 60% more than that with 0.5-μm feed/tooth. The tool failure criteria based on the width of flank wear and cutter edge radius were observed close to 27 and 9 μm, respectively. The feed/tooth adjacent to cutting edge radius was observed as the most favorable cutting condition for good tool life and surface quality.

Similar content being viewed by others

References

Masuzawa T (2000) State of the art of micromachining. CIRP Ann 49(2):473–488

Jain VK (2010) Introduction to micromachining. Narosa, New Delhi

Lu X, Jia Z, Wang H, Si L, Liu Y, Wu W (2016) Tool wear appearance and failure mechanism of coated carbide tools in micro-milling of Inconel 718 super alloy. Indust Lubri Tribol 68(2):267–277

Rahman M, Seah WKH, Teo TT (1997) The machinability of Incone1 718. J Mater Process Technol 63:199–204

Pawade RS, Joshi SS (2011) Mechanism of chip formation in high speed turning of Inconel 718. Mach Sci Technol 15(1):132–152

Camara MA, Rubio JCC, Abrao AM, Davim JP (2012) State of the art on micro-milling of materials, a review. J Mater Sci Technol 28(8):673–685

Boswell B, Islam MN, Davies IJ (2017) A review of micro-mechanical cutting. Int J Adv Manuf Technol 94(1-4):789–806

Ng CK, Melkote SN, Rahman M, Kumar AS (2006) Experimental study of micro and nano scale cutting of aluminum 7075-T6. Int J Mach Tools Manuf 46:929–936

Vipindas K, Anand KN, Mathew J (2018) Effect of cutting edge radius on micro end milling: force analysis, surface roughness, and chip formation. Int J Adv Manuf Technol 97:711–722

Aramcharoen A, Mativenga PT (2009) Size effect and tool geometry in micromilling of tool steel. Precis Eng 33:402–407

Anand RS, Patra K (2014) Modeling and simulation of mechanical micro-machining-a review. Mach Sci Technol 18(3):323–347

Oliveira FB, Rodrigues AR, Coelho RT, de Souza AF (2015) Size effect and minimum chip thickness in micromilling. Int J Mach Tools Manuf 89:39–54

Sooraj VS, Mathew J (2011) An experimental investigation on the machining characteristics of microscale end milling. Int J Adv Manuf Technol 56:951–958

Sun Z, To S (2018) Effect of machining parameters and tool wear on surface uniformity in micro-milling. Micromachines 9(6):268

Lee K, Dornfeld DA (2005) Micro-burr formation and minimization through process control. Precis Eng 29:246–252

Aurich JC, Dornfeld D, Arrazola PJ, Franke V, Leitz L, Min S (2009) Burrs-analysis, control and removal. CIRP Ann-Manuf Technol 58:519–542

Zhang T, Liu ZQ, Xu CH (2013) Influence of size effect on burr formation in micro cutting. Int J Adv Manuf Technol 68:1911–1917

Bhatt A, Attia H, Vargas R, Thomson V (2010) Wear mechanisms of WC coated and uncoated tools in finish turning of Inconel 718. Tribol Int 43:1113–1121

Zhu D, Zhang X, Ding H (2013) Tool wear characteristics in machining of nickel-based superalloys. Int J Mach Tools Manuf 64:60–77

Tanaka T, Sugihara T, Enomoto T (2016) High speed machining of Inconel 718 focusing on wear behaviors of PCBN cutting tool. Procedia CIRP 46:545–548

Hao Z, Gao D, Fan Y, Han R (2011) New observations on tool wear mechanism in dry machining Inconel 718. Int J Mach Tools Manuf 51:973–979

Fan YH, Hao ZP, Lin JQ, Yu ZX (2015) New observations on tool wear mechanism in machining Inconel 718 under water vapor + air cooling lubrication cutting conditions. J Clean Prod 90:381–387

Cantero JL, Diaz-Alvarez J, Miguelez MH, Marin NC (2013) Analysis of tool wear patterns in finishing turning of Inconel 718. Wear 297:885–894

Alhadeff LL, Marshall MB, Curtis DT, Slatter T (2019) Protocol for tool wear measurement in micro-milling. Wear 420-421:54–67

Aramcharoen A, Mativenga PT, Yang S, Cooke KE, Teer DG (2008) Evaluation and selection of hard coatings for micro milling of hardened tool steel. Int J Mach Tools Manuf 48:1578–1584

Ucun I, Aslantas K, Bedir F (2013) An experimental investigation of the effect of coating material on tool wear in micro milling of Inconel 718 super alloy. Wear 300:8–19

Devillez A, Schneider F, Dominiak S, Dudzinski D (2007) Cutting forces and wear in dry machining of Incone1 718 with coated carbide tools. Wear 262:931–942

Peng G, Zhiqiang L, Xibin W, Shidi L, Tianfeng Z (2018) Effects of different chamfered cutting edges of micro end mill on cutting performance. Int J Adv Manuf Technol 96(1-4):1215–1224

Swain N, Venkatesh V, Kumar P, Srinivas G, Ravishankar S, Barshilia HC (2017) An experimental investigation on the machining characteristics of nimonic 75 using uncoated and TiAlN coated tungsten carbide micro-end mills. CIRP J Manuf Sci Technol 16:34–42

dos Santos AG, da Silva MB, Jackson MJ (2018) Tungsten carbide micro-tool wear when micro milling UNS S32205 duplex stainless steel. Wear 414-415:109–117

Wang CY, Xie YX, Qin Z, Lin HS, Yuan YH, Wang QM (2015) Wear and breakage of TiAlN and TiSiN coated carbide tools during high speed milling of hardened steel. Wear 336–337:29–42

Vipindas K, Mathew J (2019) Wear behavior of TiAlN coated WC tool during micro end milling of Ti-6Al4V and analysis of surface roughness. Wear 424-425:165–182

Wei SL, Liu YF, Liu LF, Zhao H (2019) Investigation on tool wear process of milling wave-transmitting Si3N4 ceramics. Mater Manuf Process 34(5):521–529

Uddin MS, Pham B, Sarhan A, Basak A, Pramanik A (2017) Comparative study between wear of uncoated and TiAlN-coated carbide tools in milling of Ti6Al4V. Adv Manuf 5:83–91

Wu X, Li L, He N, Zhao G, Jiang F, Shen J (2018) Study on the tool wear and its effect of PCD tool in micro milling of tungsten carbide. Int J Refract Met Hard Mater 77:61–67

Teng X, Huo D, Shyha I, Chen W, Wong E (2018) An experimental study on tool wear behaviour in micro milling of nano Mg/Ti metal matrix composites. Int J Adv Manuf Technol 96(5-8):2127–2140

Rahman MA, Rahman M, Kumar AS (2018) Influence of relative tool sharpness (RTS) on different ultra-precision machining regimes of Mg alloy. Int J Adv Manuf Technol 96:3545–3563

Biksa A, Yamamoto K, Dosbaeva G, Veldhuis SC, Fox-Rabinovich GS, Elfizy A, Wagg T, Shuster LS (2010) Wear behavior of adaptive nano-multilayered AlTiN/Me N PVD coatings during machining of aerospace alloys. Tribol Int 43:1491–1499

Acknowledgments

The authors acknowledge the Department of Science and Technology, Government of India, for providing support to perform this study under FIST scheme (No. SR/FST/ETI-388/2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Anand Krishnan, N., Mathew, J. Studies on wear behavior of AlTiN-coated WC tool and machined surface quality in micro endmilling of Inconel 718. Int J Adv Manuf Technol 110, 291–307 (2020). https://doi.org/10.1007/s00170-020-05875-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05875-w