Abstract

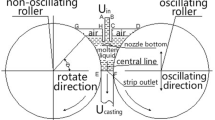

In this paper, the influence of vibration parameters on twin-roll strip vibration cast-rolling is studied. Through a comparison of vibration and nonvibration cast-rolling experiments with a 7075 aluminum alloy, it is found that the mechanical vibration introduced during the cast-rolling process can refine the grains and inhibit segregation. A thermal-flow-coupled numerical simulation model of the actual twin-roll strip vibration cast-rolling process is constructed to study the time-domain characteristics and frequency-domain characteristics of the flow field and temperature field in the molten pool, and the model is verified by experiments. The simulation results show that the disturbing effect of vibrations on the flow field in the molten pool can increase the nucleation rate by promoting dendrite fusing and inhibit the segregation of alloying elements. The vibration also affects the temperature field. During vibration cast-rolling, the height of the kiss point changes sinusoidally with time. Based on an analysis of the influence of the amplitude and vibration frequency on the temperature field and flow field, the optimal vibration parameters of the vibration cast-rolling process are determined and provide a foundation for the promotion and application of the new technology of vibration cast-rolling.

Similar content being viewed by others

References

Sahoo S, Kumar A, Dhindaw BK, Ghosh S (2012) Modeling and experimental validation of rapid cooling and solidification during high-speed twin-roll strip casting of Al-33 wt pct Cu. Metall Mater Trans B Process Metall Mater Process Sci 43(4):915–924

Pelss A, Rückert A, Pfeifer H (2015) Physical simulation of the flow field in a vertical twin roll strip caster-a water model study. Steel Res Int 86(7):716–723

Parsunkin BN, Andreev SM, Logunova OS, Akhmetov TU (2015) Energy-saving optimal control over heating of continuous cast billets. Int J Adv Manuf Technol 79(9-12):1797–1803

Rodrigues C, Ludwig A, Kharicha A, Wu M (2018) Modeling of the twin-roll casting process: transition from casting to rolling. Trans Indian Inst Metals 71(11):2645–2649

Li JT, Xu GM, Yu HL, Deng GY, Su LH, Lu C, Li HJ (2015) Optimization of process parameters in twin-roll strip casting of an AZ61 alloy by experiments and simulations. Int J Adv Manuf Technol 76(9-12):1769–1781

Zhang N, Tang P, Zhu MM, Wen G, Ma F (2010) Research metal delivery system of twin-roll thin strip continuous caster for magnesium alloys. Mater Rev 24(16):237–240

Miao YC, Zhang XM, Di HS, Wang GD (2006) Numerical simulation of the fluid flow, heat transfer, and solidification of twin-roll strip casting. J Mater Process Technol 174(1-3):7–13

Bae JW, Kang CG, Kang SB (2007) Mathematical model for the twin roll type strip continuous casting of magnesium alloy considering thermal flow phenomena. J Mater Process Technol 191(1-3):251–255

Zhang XM, Jiang ZY, Liu XH (2006) Simulation of fluid flow, heat transfer and micro-segregation in twin-roll strip casting of stainless steel. J Mater Sci Technol 22(3):295–300

Zhang XM, Jiang ZY, Yang LM, Liu XH, Wang GD, Tieu AK (2007) Modelling of coupling flow and temperature fields in molten pool during twin-roll strip casting process. J Mater Process Technol 187:339–343

Lv Z, Du F, An Z, Huang H, Xu Z, Sun J (2015) Centerline segregation mechanism of twin-roll cast A3003 strip. J Alloys Compd 643:270–274

Chang LL, Cho JH, Kang SK (2012) Microstructure and mechanical properties of twin roll cast AM31 magnesium alloy sheet processed by differential speed rolling. Mater Des 34:746–752

Gras C, Meredith M, Hunt JD (2005) Microdefects formation during the twin-roll casting of Al-Mg-Mn aluminium alloys. J Mater Process Technol 167(1):62–72

Xu ZQ, Meng ZR, Xue SH, Zhang DQ, Du FS (2018) Effect of oscillation parameters to flow field in the pool during the oscillating twin-roll strip casting process. Chin J Mech Eng 31(1):1–8

Du FS, Sun MH, Huang SG, Wei JP, Huang HG, Xu ZQ (2018) Mechanism and simulation experiments on twin-roll thin-strip vibration casting. China Mech Eng 29(4):477–484

Wei JP, Xu ZQ, Sun MH, Zhu ZW, Wang HJ, Du FS (2018) Experimental research of vibratory cast-rolling strips for 20crmn alloy steel. Ironmak Steelmak 53(12):118–121

Funding

The authors would like to thank the support from the Natural Science Foundation of Hebei Province (E2017203043), the National Natural Science Foundation of China (U1604251), and the Graduate Innovation Support Program of Yanshan University (CXZS201901).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, M., Zhu, Z., Zheng, L. et al. Study on the influence of vibration parameters in the twin-roll strip vibration cast-rolling process. Int J Adv Manuf Technol 108, 3141–3157 (2020). https://doi.org/10.1007/s00170-020-05432-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05432-5