Abstract

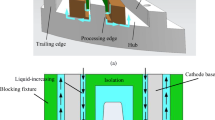

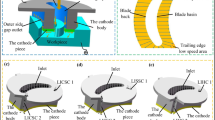

The diffuser is a key part of the aircraft engine, and electrochemical machining (ECM) is one of the main methods to process it. In the ECM of a diffuser, the suitability of the flow field determines whether the ECM can be successful. A suitable flow field can not only improve the stability of the machining, but also influence its machining efficiency and surface quality. A diffuser with a special structure is processed by the method of electrochemical trepanning in this paper. A back pressure is added to the machining zone, which is different from the outlet-open flow mode always used in traditional machining method, and the outlet-cornered gap is optimized. Simulation results show that the uniformity of the flow field is optimal when the outlet-cornered gap ζ is 0.35 mm. Furthermore, the experimental investigations are carried out, and the results show that when the feed rate of the cathode is increased from 0.5 to 0.7 mm/min, the blade accuracy is enhanced.

Similar content being viewed by others

References

Gu ZZ, Zhu D, Xue TY, Liu A, Zhu D (2017) Investigation on flow field in electrochemical trepanning of aero engine diffuser. Int J Adv Manuf Technol 2017 89(1):877–884

Klocke F, Klink A, Veselovac D, Aspinwall DK, Soo SL, Schmidt M, Schilp J, Levy G, Kruth JP (2014) Turbomachinery component manufacture by application of electrochemical, electrophysical and photonic processes. CIRP Ann Manuf Technol 63(2):703–726

Klocke F, Zeis M, Klink A, Veselovac D (2013) Experimental research on the electrochemical machining of modern titanium and nickel-based alloys for aero engine components. Procedia CIRP 6:368–372

Rajurkar KP, Zhu D, McGeough JA, Kokaz J, Silva D (1999) A new development in electrochemical machining. CIRP Ann Manuf Technol 48(2):567–579

Kang M, Fu XQ, Yang Y (2011) Research on flow field characteristics and experiments of numerical control electrochemical machining. J Comput Theor Nanos 4(6):1933–1938

Kozak J (2001) Computer simulation system for electrochemical shaping. J Mater Process Technol 109(3):354–359

Wang FY, Xu JW, Zhao JS (2011) Numerical simulation of electrochemical machining process and machined surface prediction. Key Eng Mater 458:99–105

Yamamoto M (2013) Multi-physics CFD simulations in engineering. Therm Sci 22(4):287–293

Dietz H, Gunther KG, Otto K (1974) Electrochemical machining: calculation of side gap with respect to hydrogen evolution. Ann CIRP 23:45–46

Zhu D, Zhu D, Xu ZY (2012) Optimal design of the sheet cathode using W-shaped electrolyte flow mode in ECM. Int J Adv Manuf Technol 62(1):147–156

Wang DY, Zhu ZW, Bao J, Zhu D (2015) Reduction of stray corrosion by using iron coating in NaNO3 solution during electrochemical machining. Int J Adv Manuf Technol 76:1365–1370

Funding

This work was supported by the National Natural Science Foundation of China (91860135), the Natural Science Foundation of Jiangsu Province (BK20171413), and the Fundamental Research Funds for the Central Universities (NE 2017003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, J., Zhu, D., Lin, J. et al. Flow field design and experimental investigation of electrochemical trepanning of diffuser with a special structure. Int J Adv Manuf Technol 107, 1551–1558 (2020). https://doi.org/10.1007/s00170-020-05091-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05091-6