Abstract

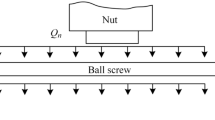

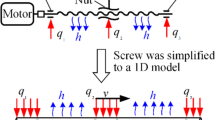

The thermal characteristic of the ball screw feed drive system has great influence on machining accuracy as its thermal deformation would induce the positioning deviation. In this paper, finite difference method was applied to simulate the temperature distribution and thermal growth of the ball screw feed drive system under various working conditions. When simulating, the nut was considered a moving heat source, and the boundary conditions were optimized based on response surface methodology. By comparing the simulation results with the testing data, it was verified that the accuracy of the simulation could be improved by using the proposed method.

Similar content being viewed by others

References

Horejs, O (2007) Thermo-mechanical model of ball screw with non-steady heat sources. in International Conference on Thermal Issues in Emerging Technologies: Theory & Application.

Li TJ, Zhao C-Y, Zhang Y-M (2018) Adaptive real-time model on thermal error of ball screw feed drive systems of CNC machine tools. Int J Adv Manuf Technol 94(9–12):3853–3861

Kim SK, Cho DW (1997) Real-time estimation of temperature distribution in a ball-screw system. Int J Mach Tool Manu 37(4):451–464

Liu K, Liu Y, Sun M, Wu Y, Zhu T (2016) Comprehensive thermal compensation of the servo axes of CNC machine tools. Int J Adv Manuf Technol 85(9–12):2715–2728

Li B, Tian X, Zhang M (2019) Thermal error modeling of machine tool spindle based on the improved algorithm optimized BP neural network. Int J Adv Manuf Technol 105:1497–1505

Liu D-S, Lin P-C, Lin J-J, Wang CR, Shiau TN (2019) Effect of environmental temperature on dynamic behavior of an adjustable preload double-nut ball screw. Int J Adv Manuf Technol 101(9–12):2761–2770

Li R, Lin W, Zhang J, Chen Z, Li C, Shuang Q (2018) Research on thermal deformation of feed system for high-speed vertical machining center. Procedia Comput Sci 131:469–476

Min X, Jiang S (2011) A thermal model of a ball screw feed drive system for a machine tool. P I Mech Eng C-J Mec 225(1):186–193

Oyanguren A, Larrañaga J, Ulacia I (2018) Thermo-mechanical modelling of ball screw preload force variation in different working conditions. Int J Adv Manuf Technol 2:1–17

Li TJ, Zhao CY, Zhang YM (2018) Adaptive real-time model on thermal error of ball screw feed drive systems of CNC machine tools. Int J Adv Manuf Technol 94(9–12):3853–3861

Wu CH, Kung YT (2003) Thermal analysis for the feed drive system of a CNC machine center. Int J Mach Tool Manu 43(15):1521–1528

Xu ZZ, Choi C, Liang LJ, Li DY, Lyu SK (2015) Study on a novel thermal error compensation system for high-precision ball screw feed drive (1st report: model, calculation and simulation). Int J Precis Eng Manuf 16(9):2005–2011

Shi H, Zhang D, Yang J, Ma C, Mei X, Guo G (2016) Experiment-based thermal error modeling method for dual ball screw feed system of precision machine tool. Int J Adv Manuf Technol 82(9–12):1693–1705

Shi H, Ma C, Yang J, Zhao L, Mei X, Guo G (2015) Investigation into effect of thermal expansion on thermally induced error of ball screw feed drive system of precision machine tools. Int J Mach Tool Manu 97:60–71

Yang J, Mei X, Feng B, Zhao L, Ma C, Shi H (2015) Experiments and simulation of thermal behaviors of the dual-drive servo feed system. Chin J Mech Eng-En 28(1):76–87

Harris TA (1991) Rolling bearing analysis. Wiley, New York

Lienhard JH, Lienhard J (2000) A heat transfer textbook. Phlogiston Press, Cambridge, Massachusetts

Montgomery D (2007) Design and analysis of experiments. 6th Edition, John Wiley & Sons, New York

ISO (2006) 230-2:Test code for machine tools—part 2: determination of accuracy and repeatability of positioning numerically controlled axes.

ISO (2007) 230-3: Test code for machine tools—part 3: determination of thermal effects.

Funding

The work has been supported the State Key Laboratory for Manufacturing System Engineering (China), National Natural Science Foundation of China(51705402), National Science and Technology Major Project of China(Grant No. 2017ZX04013001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Wei, W., Su, D. et al. Thermal characteristic analysis of ball screw feed drive system based on finite difference method considering the moving heat source. Int J Adv Manuf Technol 106, 4533–4545 (2020). https://doi.org/10.1007/s00170-020-04936-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-04936-4