Abstract

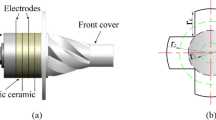

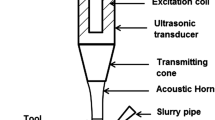

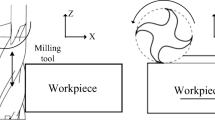

Longitudinal-torsional (L-T) vibration in rotary ultrasonic machining (RUM) can further reduce the cutting force and improve the machining efficiency compared with the single longitudinal vibration in RUM. In this study, an ultrasonic step horn with spiral slots using the principle of mode conversion was designed to realize L-T vibration. The torsional amplitude to longitudinal amplitude (AT/AL) ratio is proposed to quantify the efficiency of mode conversion. Moreover, a simulation method was used to carry out the frequency coupling design of the ultrasonic horn with spiral slots. The influence of the step position and slot position with a spiral angle of 52° on the resonant frequency and amplitude of the ultrasonic horn were analyzed, respectively. Based on the simulation results, ultrasonic horns with different AT/AL were designed and fabricated. Finally, the results obtained through experiments with milling glass plane revealed that the cutting force was reduced by 48–73%, while the surface quality improved compared with single longitudinal vibration when the torsional vibration is coupled with the longitudinal vibration in RUM. The reasonable AT/AL ratio could effectively reduce the cutting force when the synthetic amplitude was the same. This indicates that the L-T vibration changes the trajectories of the diamond abrasives, which improves the machining performance.

Similar content being viewed by others

References

Zha H, Feng P, Zhang J, Yu D, Wu Z (2018) Material removal mechanism in rotary ultrasonic machining of high-volume fraction SiCp/Al composites. Int J Adv Manuf Technol 97(5–8):2099–2109. https://doi.org/10.1007/s00170-018-2075-x

Wang J, Zhang C, Feng P, Zhang J (2016) A model for prediction of subsurface damage in rotary ultrasonic face milling of optical K9 glass. Int J Adv Manuf Technol 83(1–4):347–355. https://doi.org/10.1007/s00170-015-7567-3

Sayuti M, Sarhan AAD, Fadzil M, Hamdi M (2012) Enhancement and verification of a machined surface quality for glass milling operation using CBN grinding tool-Taguchi approach. Int J Adv Manuf Technol 60(9–12):939–950. https://doi.org/10.1007/s00170-011-3657-z

Wan Z, Tang Y (2009) Brittle–ductile mode cutting of glass based on controlling cracks initiation and propagation. Int J Adv Manuf Technol 43(11–12):1051–1059. https://doi.org/10.1007/s00170-008-1782-0

Tosun G, Muratoglu M (2004) The drilling of Al/SiCp metal-matrix composites. Part II: workpiece surface integrity. Compos Sci Technol 64(10–11):1413–1418. https://doi.org/10.1016/j.compscitech.2003.07.007

Tosun G, Muratoglu M (2004) The drilling of an Al/SiCp metal-matrix composites. Part I: microstructure. Compos Sci Technol 64(2):299–308. https://doi.org/10.1016/S0266-3538(03)00290-2

Zhou M, Ngoi BKA, Yusoff MN, Wang XJ (2006) Tool wear and surface finish in diamond cutting of optical glass. J Mater Process Technol 174:29–33. https://doi.org/10.1016/j.jmatprotec.2005.02.248

Li ZC, Cai L, Pei ZJ, Treadwell C (2006) Edge-chipping reduction in rotary ultrasonic machining of ceramics: finite element analysis and experimental verification. Int J Mach Tools Manuf 46(12–13):1469–1477. https://doi.org/10.1016/j.ijmachtools.2005.09.002

Zhang C, Zhang J, Feng P (2013) Mathematical model for cutting force in rotary ultrasonic face milling of brittle materials. Int J Adv Manuf Technol 69(1–4):161–170. https://doi.org/10.1007/s00170-013-5004-z

Nath C, Lim G, Zheng H (2012) Influence of the material removal mechanisms on hole integrity in ultrasonic machining of structural ceramics. Ultrasonics 52(5):605–613. https://doi.org/10.1016/j.ultras.2011.12.007

Gong H, Fang F, Hu X (2010) Kinematic view of tool life in rotary ultrasonic side milling of hard and brittle materials. Int J Mach Tools Manuf 50(3):303–307. https://doi.org/10.1016/j.ijmachtools.2009.12.006

Shen X, Zhang J, Xing D, Zhao Y (2012) A study of surface roughness variation in ultrasonic vibration-assisted milling. Int J Adv Manuf Technol 58(5–8):553–561. https://doi.org/10.1007/s00170-011-3399-y

Cardoni A, Harkness P, Lucas M (2010) Ultrasonic rock sampling using longitudinal-torsional vibrations. Phys Procedia 3:125–134. https://doi.org/10.1016/j.phpro.2010.01.018

Xiang D, Yang G, Liang S. (2014) Study on milling force of high volume fraction SiCp/Al composites with ultrasonic longitudinal and torsional vibration high speed milling. Jpn.j.appl.phys 56(7S1):07JE02. doi: https://doi.org/10.4028/www.scientific.net/amr.910.114

Asami T, Miura H (2015) Study of ultrasonic machining by longitudinal-torsional vibration for processing brittle materials-observation of machining marks. Phys Procedia 70:118–121. https://doi.org/10.1016/j.phpro.2015.08.056

Lin S (1997) Sandwiched Piezloelectric ultrasonic transducers of longitudinal-torsional compound vibrational modes. IEEE Trans Ultrason Ferroelectr Freq Control 44(6):1189–1197. https://doi.org/10.1109/58.656619

Zhou T, Zhang L, Xue Y (1999) Study on the degeneracy of resonant frequency of torsional ultrasonic motor vibration system. Piezoelectrics and Acoustooptics 21(2):71–73. https://doi.org/10.1016/B978-008043005-8/50007-X

Karafi MR, Ghodsi M, Hojjat Y (2015) Development of magnetostrictive resonant torsional vibrator. IEEE Trans Magn 51(9):1–8. https://doi.org/10.1109/TMAG.2015.2427279

Karafi MR, Hojjat Y, Sassani F, Ghodsi M (2013) A novel magnetostrictive torsional resonant transducer. Sensors Actuators A Phys 195:71–78. https://doi.org/10.1016/j.sna.2013.03.015

Tsujino J, Ueoka T, Otoda K, Fujimi A (2000) One-dimensional longitudinal–torsional vibration converter with multiple diagonally slitted parts. Ultrasonics 38(1–8):72–76. https://doi.org/10.1016/S0041-624X(99)00175-4

Harkness P, Cardoni A, Lucas M (2009) Ultrasonic rock drilling devices using longitudinal-torsional compound vibration. IEEE Int Ultrason Symp 2009:2088–2091. https://doi.org/10.1109/ULTSYM.2009.0516

Liu C, Wu H, Luo A (2013) Design of longitudinal-torsional vibration stepped horn with multiple diagonal slits. Appl Mech Mater 312:51–54. https://doi.org/10.4028/www.scientific.net/AMM.312.51

Jun P (2008) Longitudinal-torsional vibration converter of cylinder with multiple diagonal slits. Chin J Mech Eng 44(5):242–248. https://doi.org/10.3321/j.issn:0577-6686.2008.05.041

Rose J (2014) Ultrasonic guided waves in solid. Plates. Cambridge University Press, Media. https://doi.org/10.1017/CBO9781107273610

Zhang Q, Zhang J, Feng P (2019) Characteristics of longitudinal-torsional vibration of ultrasonic horn with slanting slots. J Vibr Shock 38(10). https://doi.org/10.13465/j.cnki.jvs.2019.10.009

Cai W, Zhang J, Feng P, Yu D, Wu Z (2017) A bilateral capacitance compensation method for giant magnetostriction ultrasonic processing system. Int J Adv Manuf Technol 90(9–12):2925–2933. https://doi.org/10.1007/s00170-016-9602-4

Xiao X, Zheng K, Liao W (2014) Theoretical model for cutting force in rotary ultrasonic milling of dental zirconia ceramics. Int J Adv Manuf Technol 75(9–12):1263–1277. https://doi.org/10.1007/s00170-014-6216-6

Funding

The authors gratefully acknowledge the financial support provided to this study by the National Natural Science Foundation of China (Grant Nos. 51761145103 and 51875311) and the Shenzhen Fundamental Research and Discipline Layout project (Grant No. JCYJ2016042818191622).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pang, Y., Feng, P., Zhang, J. et al. Frequency coupling design of ultrasonic horn with spiral slots and performance analysis of longitudinal-torsional machining characteristics. Int J Adv Manuf Technol 106, 4093–4103 (2020). https://doi.org/10.1007/s00170-019-04898-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04898-2