Abstract

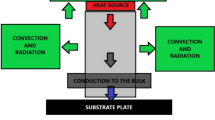

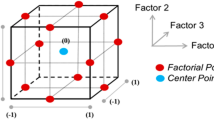

Friction stir-assisted incremental sheet forming with synchronous bonding is developed as a novel variant of incremental sheet forming, by which the two sheet metals form incrementally and get bonded simultaneously. Numerical simulation of this process is crucial in revealing the forming mechanism and optimizing the process compared with expensive physical tryouts. A coupled thermo-mechanical finite element model was established to take the contact and heat transformation in every interface into consideration, and VUINTER contact subroutine which can express the heat partition coefficient and coefficient of friction was complied, validated and revised by groove tests. The effectiveness of the numerical simulation was verified by experiments. Furthermore, a comparative study based on numerical simulation is conducted to analyze the effects of process variables including feed rate, spindle speed, wall angle and vertical step size on temperature, thickness, and central bulge.

Similar content being viewed by others

Abbreviations

- d :

-

vertical step size (mm)

- v f :

-

feed rate of the tool (mm/min)

- v s :

-

spindle speed of the tool (RPM)

- v :

-

sliding velocity of the contact point in the tool/sheet interface (mm/s)

- ΔD :

-

distance of relative motion between the contact nodes on master surface and slave surface (mm)

- g N :

-

penetration distance (mm)

- n s :

-

value of penalty stiffness for each node

- T :

-

temperature (°C)

- T 0 :

-

ambient temperature (°C)

- T 1 :

-

temperature of the upper sheet (°C)

- T 2 :

-

temperature of the lower sheet (°C)

- T 3 :

-

temperature of the back sheet (°C)

- T 4 :

-

temperature of the forming tool (°C)

- T 5 :

-

temperature of the blank holder (°C)

- f :

-

friction stress (MPa)

- τ max :

-

shear stress limit (MPa)

- q fric :

-

heat generated by friction (mW/mm2)

- q →t :

-

heat flowing into the tool (mW/mm2)

- q →u :

-

heat flowing into the upper sheet (mW/mm2)

- q →l :

-

heat flowing into the lower sheet (mW/mm2)

- q →b :

-

heat flowing into the back sheet (mW/mm2)

- β →t :

-

friction heat partition coefficient

- h c 1 :

-

heat conductivity in tool/upper-sheet interface (mW/mm2 ∙ ° C)

- h c 2 :

-

heat conductivity in upper-sheet/lower-sheet interface (mW/mm2 ∙ ° C)

- h c 3 :

-

heat conductivity in lower-sheet/back-sheet interface (mW/mm2 ∙ ° C)

- h s 1 :

-

coefficient of heat dissipation for air (mW/mm2 ∙ ° C)

- h s 2 :

-

coefficient of heat dissipation for blank-holder (mW/mm2 ∙ ° C)

- η :

-

efficiency of the heat converted by the work done by friction

- β :

-

coefficient of heat partition

- μ :

-

coefficient of friction

- ρ :

-

density (kg/m3)

- E :

-

elastic modulus (GPa)

- γ :

-

Poisson ratio

- c p :

-

specific heat (J/kg/°C)

- λ :

-

thermal conductivity of material (W/m/°C)

- σ n :

-

contact stress (MPa)

- σ s :

-

yield stress (MPa)

- α :

-

wall angle (°)

References

Peng D, Liu L, Zhu X (2000) Review in research and development of clad metal sheets. Mater Rev 14:23–24

Shi F, Zhao X, Xia Q (2012) Research on drawing process of two layer sheet steel based on numerical simulation. Mod Manuf Eng 2:99–104

Sun M, Niknejad S, Zhang G (2015) Microstructure and mechanical properties of resistance spot welded AZ31/AA5754 using a nickel interlayer. Mater Des 87:905–913

Li M, Cai Z, Liu C (2007) Flexible manufacturing of sheet metal parts based on digitized-die. Robot CIM-Int Manuf 23:107–115

Zhu H, Kang J (2007) Sheet metal dieless incremental forming based on CNC machine tool. Forging Stamping Technol 32(1):88–90

Zhou L, Mo J, Xiao X (2003) A study of NC incremental sheet parts forming process. J Plast Eng 10(4):27–29

Gheysarian A, Honarpisheh M (2018) Process parameters optimization of the explosive-welded Al/Cu bimetal in the incremental sheet metal forming process. Iran J Sci Technol Trans Mech Eng:1–12

Honarpishen M, Keimasi M, Alinaghian I (2018) Numerical and experimental study on incremental forming process of Al/Cu bimetals. J Mech Mater Struct 13:35–50

Sakhtemanian M, Honarpisheh M, Amini S (2018) Numerical and experimental study on the layer arrangement in the incremental forming process of explosive-welded low-carbon steel/CP-titanium bimetal sheet. Int J Adv Manuf Technol 95:3781–3796

Conte R, Ambrogio G, Filice L, Gagliardi F, Russo P (2017) Preliminary experimental analysis on incremental forming of fiberglass reinforces polyamide AITEM

Contea R, Ambrogioa G, Pulicea D, Gagliardia F, Filicea L (2017) Incremental sheet forming of a composite made of thermoplastic matrix and glass-fiber reinforcement. Int Conf Techonol Plast 207:819–824

Suresh K, Regalla S (2013) Simulation of forces and strains in single point incremental forming process. J Mach Form Technol 6:79–99

Wang HY, Chen J (2017) Novel strategies to reduce the springback for double-sided incremental forming. Int J Adv Manuf Technol 96:973–979

Nguyen D, Park J, Kim Y (2009) Analytical and numerical approach to predict the fracture and optimize the press formability of incremental sheet forming for complex shape

Sena J, Sousa RJ, Valente R (2010) Single point incremental forming simulation with an enhanced assumed strain solid-shell finite element formulation. Int J Mater Form 3(1):963–966

Capece F, Durante M, Formisano A, Langella A (2007) Evaluation of the maximum slope angle of simple geometries carried out by incremental forming process. J Mater Process Technol 194:145–150

Wang J, Song L, Li L (2015) Numerical simulation research on sheet temperature rise of rolling incremental sheet forming. Hot Work Technol 44(23):133–136

Nguyen D, Park J, Kim Y (2010) Combined kinematic/isotropic behavior study for magnesium alloy sheets to predict ductile fracture of rotational incremental forming. Int J Mater Form 3(Suppl 1):939–942

Nguyen D, Park J (2010) Ductile fracture prediction in rotational incremental forming for magnesium alloy sheets using combined kinematic/isotropic hardening model. Metall Mater Trans A 41A:1983–1994

Giuseppina A, Claudio C, Luigino F, Francesco G (2016) Theoretical model for temperature prediction in incremental sheet forming – experimental validation. Int J Mech Sci 108-109:39–48

Xu D, Wu W, Malhotra R, Chen J, Lu B, Cao J (2013) Mechanism investigation for the influence of tool rotation and laser surface texturing (LST) on formability in single point incremental forming. Int J Mach Tool Manu 73:37–46

Atlati S, Haddag B, Nouari M, Zenasni M (2014) Thermomechanical modelling of the tool–workmaterial interface in machining and its implementation using the ABAQUS VUINTER subroutine. Int J Mech Sci 87:102–117

Zhang B, Allegri G, Hallett S (2013) Micro-mechanical finite element analysis of single Z-pin pull-out. 2013 Simulia UK regional user meeting

Diabb J, Rodríguez C, Mamidi N, Sandoval J, Taha-Tijerina J (2017) Study of lubrication and wear in single point incremental sheet forming (SPIF) process using vegetable oil nanolubricants. Wear. 376-377:777–785

Chao Y, Qi X, Tang W (2003) Heat transfer in friction stir welding—experimental and numerical studies. J Manuf Sci E-T ASME 125:138–145

Courbon C, Mabrouki T, Rech J, Mazuyer D, Eramo E (2011) New thermal issues on the modelling of tool-workpiece interaction: application to dry cutting of AISI 1045 steel. Adv Mater Res 223:286–295

Kang S, Jang B (2014) Comparison of friction stir welding heat transfer analysis methods and parametric study on unspecified input variable. J Mech Sci Technol 28(10):4233–4246

Avitzur B (1961) A theory of shear spinning of cones. J Eng Ind 83(4):494

Khalid A, Hussain G (2019) Bulging in ISF of cold bonded multi-layered Cu clad sheet: influence of forming conditions and bending. Trans Nonferrous Metal Soc 29:112–122

Hussian G, Al-Ghamdi KA (2014) Forming parameters and forming defects in incremental forming: part B. Mater Manuf Process 29:454–460

Al-Ghamdi KA, Hussain G (2015) The pillowing tendency of materials in incremental forming: experimental and FE analyses. Proc IMechE J Eng Manuf 229:744–753

Acknowledgements

The authors are grateful for the financial support from National Natural Science Foundation of China through grant no. 51675332 and the Program of Shanghai Excellent Academic Research Leadership through grant no. 19XD1401900.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cai, S., Wu, R., Wang, Z. et al. Numerical simulation of friction stir-assisted incremental forming with synchronous bonding of heterogeneous sheet metals. Int J Adv Manuf Technol 106, 2747–2763 (2020). https://doi.org/10.1007/s00170-019-04792-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04792-x