Abstract

This paper introduces a new hybrid optimization algorithm (HWOANM) based on the Nelder–Mead local search algorithm (NM) and whale optimization algorithm (WOA). The aim of hybridization is to accelerate global convergence speed of the whale algorithm for solving manufacturing optimization problems. The main objective of our study on hybridization is to accelerate the global convergence rate of the whale algorithm to solve production optimization problems. This paper is the first research study of both the whale algorithm and HWOANM for the optimization of processing parameters in manufacturing processes. The HWOANM is evaluated using the well-known benchmark problems such as cantilever beam problem, welded beam problem, and three-bar truss problem. Finally, a grinding manufacturing optimization problem is solved to investigate the performance of the HWOANM. The results of the HWOANM for both the design and manufacturing problems solved in this paper are compared with other optimization algorithms presented in the literature such as the ant colony algorithm, genetic algorithm, scatter search algorithm, differential evolution algorithm, particle swarm optimization algorithm, simulated annealing algorithm, artificial bee colony algorithm, improved differential evolution algorithm, harmony search algorithm, hybrid particle swarm algorithm, teaching-learning–based optimization algorithm, cuckoo search algorithm, grasshopper optimization algorithm, salp swarm optimization algorithm, mine blast algorithm, gravitational search algorithm, ant lion optimizer, multi-verse optimizer, whale optimization algorithm, and the Harris hawks optimization algorithm. The results show that the HWOANM provides better exploration and exploitation properties, and can be considered as a promising new algorithm for optimizing both design and manufacturing optimization problems.

Similar content being viewed by others

References

Yildiz AR, Yildiz BS, Sait SM, Li XY (2019) The Harris hawks, grasshopper and multi-verse optimization algorithms for the selection of optimal machining parameters in manufacturing operations. Materials Testing 61(8):725–733

Yildiz AR, Yildiz BS, Sait SM, Bureerat S, Pholdee N (2019) A new hybrid Harris hawks Nelder-Mead optimization algorithm for solving design and manufacturing problems. Materials Testing 61(8):735–743

Yildiz AR (2013) Cuckoo search algorithm for the selection of optimal machining parameters in milling operations. Int J Adv Manuf Technol 64(1-4):55–61

Yildiz AR, Abderazek H, Mirjalili S (2019) A comparative study of recent non-traditional methods for mechanical design optimization. Arch Comput Methods Eng:1–18. https://doi.org/10.1007/s11831-019-09343-x

Yildiz AR (2012) A comparative study of population-based optimization algorithms for turning operations. Inf Sci 210:81–88

Yildiz AR (2013) A new hybrid differential evolution algorithm for the selection of optimal machining parameters in milling operations. Appl Soft Comput 13(3):1561–1566

Yildiz AR (2013) Hybrid Taguchi-differential evolution algorithm for optimization of multi-pass turning operations. Appl Soft Comput 13(3):1433–1439

Yıldız AR (2009) A novel hybrid immune algorithm for global optimization in design and manufacturing. Robot Comput Integr Manuf 25(2):261–270

Yıldız AR (2009) An effective hybrid immune-hill climbing optimization approach for solving design and manufacturing optimization problems in industry. J Mater Process Technol 209(6):2773–2780

Yildiz AR (2013) A new hybrid artificial bee colony algorithm for robust optimal design and manufacturing. Appl Soft Comput 13(5):2906–2912

Yildiz AR, Ozturk F (2006) Hybrid enhanced genetic algorithm to select optimal machining parameters in turning operation. Proc Inst Mech Eng B J Eng Manuf 220(12):2041–2053

Yildiz BS, Yildiz AR (2019) The Harris hawks optimization algorithm, salp swarm algorithm, grasshopper optimization algorithm and dragonfly algorithm for structural design optimization of vehicle components. Materials Testing 61(8):744–748

Khalilpourazari S, Khalilpourazary S (2017) A lexicographic weighted Tchebycheff approach for multi-constrained multi-objective optimization of the surface grinding process. Eng Optim 49(5):878–895

Taylor FW (1906) On the art of cutting metals. American society of mechanical engineers

Wang ZG, Rahman M, Wong YS, Sun J (2005) Optimization of multi-pass milling using parallel genetic algorithm and parallel genetic simulated annealing. Int J Mach Tools Manuf 45(15):1726–1734

Gilbert WW (1950) Economics of machining. Machining-Theory Pract:465–485

Okushima K, Hitomi K (1964) A study of economical machining: an analysis of the maximum-profit cutting speed. Int J Prod Res 3(1):73–78

Ermer DS (1971) Optimization of the constrained machining economics problem by geometric programming. J Eng Ind 93(4):1067–1072

Petropoulos PG (1973) Optimal selection of machining rate variables by geometric programming. THE INTERNATIONAL JOURNAL OF PRODUCTION RESEARCH 11(4):305–314

Boothroyd G (1976) Maximum rate of profit criteria in machining. Trans ASME J Eng Ind:217–220

Hati SK, Rao SS (1976) Determination of optimum machining conditions—deterministic and probabilistic approaches. J Eng Ind 98(1):354–359

Iwata K, Murotsu Y, Oba F (1977) Optimization of cutting conditions for multi-pass operations considering probabilistic nature in machining processes. J Eng Ind 99(1):210–217

Lambert BK, Walvekar AG (1978) Optimization of multi-pass machining operations. Int J Prod Res 16(4):259–265

Chen MC, Tsai DM (1996) A simulated annealing approach for optimization of multi-pass turning operations. Int J Prod Res 34(10):2803–2825

Ermer DS, Kromodihardjo S (1981) Optimization of multipass turning with constraints. J Eng Ind 103(4):462–468

Gopalakrishnan B, Al-Khayyal F (1991) Machine parameter selection for turning with constraints: an analytical approach based on geometric programming. Int J Prod Res 29(9):1897–1908

Shin YC, Joo YS (1992) Optimization of machining conditions with practical constraints. Int J Prod Res 30(12):2907–2919

Gupta R, Batra JL, Lal GK (1995) Determination of optimal subdivision of depth of cut in multipass turning with constraints. Int J Prod Res 33(9):2555–2565

Tan FP, Creese RC (1995) A generalized multi-pass machining model for machining parameter selection in turning. Int J Prod Res 33(5):1467–1487

Agapiou JS (1992) The optimization of machining operations based on a combined criterion, part 2: Multipass operations. J Eng Ind 114(4):508–513

Armarego EJA, Smith AJR, Wang J (1993) Constrained optimization strategies and CAM software for single-pass peripheral milling. THE INTERNATIONAL JOURNAL OF PRODUCTION RESEARCH 31(9):2139–2160

Armarego EJA, Smith AJR, Wang J (1994) Computer-aided constrained optimization analyses and strategies for multipass helical tooth milling operations. CIRP Annals-Manuf Technol 43(1):437–442

Tolouei-Rad M, Bidhendi IM (1997) On the optimization of machining parameters for milling operations. Int J Mach Tools Manuf 37(1):1–16

Hamza F, Abderazek H, Lakhdar S, Ferhat D, Yildiz AR (2018) Optimum design of camroller follower mechanism using a new evolutionary algorithm. The International Journal of Advanced Manufacturing Technology 99(5-8):1261–1282

Yildiz BS, Yildiz AR (2018) Comparison of the grey wolf, whale, water cycle, ant lion and sine-cosine algorithms for the optimization of a vehicle engine connecting rod. Materials Testing 60(3):311–315

Pholdee N, Bureerat S, Yildiz AR (2017) Hybrid real-code population-based incremental learning and differential evolution for many-objective optimisation of an automotive floorframe. International Journal of Vehicle Design,73(1-3):20–53

Yildiz BS (2017) A comparative investigation of eight recent population-based optimisation algorithms for mechanical and structural design problems. International Journal of Vehicle Design73(1-3):208–218

Kiani M, Yildiz AR (2016) A comparative study of non-traditional methods for vehicle crashworthiness and NVH optimization. Archives of Computational Methods in Engineering 23(4):723–734

Yildiz BS, H. Lekesiz H, Yildiz AR (2016) Structural design of vehicle components using gravitational search and charged system search algorithms. Materials Testing 58(1):79–81

Yildiz AR (2013) Comparison of evolutionary based optimization algorithms for structural design optimization. Engineering Applications of Artificial Intelligence 26(1):327–333

Yildiz AR, Saitou K (2011) Topology Synthesis of Multi-Component Structural Assemblies in Continuum Domains. Transactions of ASME Journal of Mechanical Design 133(1):011008–9.

Yildiz AR, Solanki K (2012) Multi-objective optimization of vehicle crashworthiness using new particle swarm based approach. International Journal of Advanced Manufacturing Technology, 59(1-4):367–376

Mirjalili S, Lewis A (2016) The whale optimization algorithm. Adv Eng Softw 95:51–67

Saremi S, Mirjalili S, Lewis A (2017) Grasshopper optimisation algorithm: theory and application. Adv Eng Softw 105:30–47

Mirjalili S, Gandomi AH, Mirjalili SZ, Saremi S, Faris H, Mirjalili SM (2017) Salp swarm algorithm: a bio-inspired optimizer for engineering design problems. Adv Eng Softw 114:163–191

Mirjalili S, Mirjalili SM, Lewis A (2014) Grey wolf optimizer. Adv Eng Softw 69:46–61

Mirjalili S (2016) Dragonfly algorithm: a new meta-heuristic optimization technique for solving single-objective, discrete, and multi-objective problems. Neural Comput & Applic 27(4):1053–1073

Mirjalili S (2015) Moth-flame optimization algorithm: a novel nature-inspired heuristic paradigm. Knowl-Based Syst 89:228–249

Mirjalili S (2015) The ant lion optimizer. Adv Eng Softw 83:80–98

Eberhart R, Kennedy J (1995) A new optimizer using particle swarm theory. In Micro Machine and Human Science, 1995. MHS’95., Proceedings of the Sixth International Symposium on (pp. 39-43). IEEE

Yang XS, Deb S (2009) Cuckoo search via Lévy flights. In Nature & Biologically Inspired Computing, 2009. NaBIC 2009. World Congress on (pp. 210-214). IEEE

Mirjalili S, Mirjalili SM, Hatamlou A (2016) Multi-verse optimizer: a nature-inspired algorithm for global optimization. Neural Comput & Applic 27(2):495–513

Heidari A, Mirjalili S, Farris H, Aljarah I, Mafarja M (2019) Chen H.(2019). Harris hawks optimization: algorithm and applications. Futur Gener Comput Syst 97:849–872. https://doi.org/10.1016/j.future.2019.02.028

Mirjalili S (2016) SCA: a sine cosine algorithm for solving optimization problems. Knowl-Based Syst 96:120–133

Eskandar H, Sadollah A, Bahreininejad A, Hamdi M (2012) Water cycle algorithm–a novel metaheuristic optimization method for solving constrained engineering optimization problems. Comput Struct 110:151–166

Sadollah A, Eskandar H, Bahreininejad A, Kim JH (2015) Water cycle algorithm for solving multi-objective optimization problems. Soft Comput 19(9):2587–2603

Dhiman G, Kaur A (2019) STOA: a bio-inspired based optimization algorithm for industrial engineering problems. Eng Appl Artif Intell 82:148–174

Yıldız BS, Yıldız AR (2017) Moth-flame optimization algorithm to determine optimal machining parameters in manufacturing processes. Materials Testing 59(5):425–429

Wen XM, Tay AAO, Nee AYC (1992) Micro-computer-based optimization of the surface grinding process. J Mater Process Technol 29(1-3):75–90

Saravanan R, Asokan P, Sachidanandam M (2002) A multi-objective genetic algorithm (GA) approach for optimization of surface grinding operations. Int J Mach Tools Manuf 42(12):1327–1334

Baskar N, Saravanan R, Asokan P, Prabhaharan G (2004) Ants colony algorithm approach for multi-objective optimisation of surface grinding operations. Int J Adv Manuf Technol 23(5-6):311–317

Krishna AG, Rao KM (2006) Multi-objective optimisation of surface grinding operations using scatter search approach. Int J Adv Manuf Technol 29(5-6):475–480

Lee KM, Hsu MR, Chou JH, Guo CY (2011) Improved differential evolution approach for optimization of surface grinding process. Expert Syst Appl 38(5):5680–5686

Zhang G, Liu M, Li J, Ming W, Shao X, Huang Y (2014) Multi-objective optimization for surface grinding process using a hybrid particle swarm optimization algorithm. Int J Adv Manuf Technol 71(9-12):1861–1872

Krishna AG (2007) Retracted: optimization of surface grinding operations using a differential evolution approach. https://doi.org/10.1016/j.jmatprotec.2006.10.010

Lin X, Li H (2008) Enhanced Pareto particle swarm approach for multi-objective optimization of surface grinding process. In Intelligent Information Technology Application, 2008. IITA’08. Second International Symposium on (Vol. 2, pp. 618-623). IEEE

Gupta R, Shishodia KS, Sekhon GS (2001) Optimization of grinding process parameters using enumeration method. J Mater Process Technol 112(1):63–67

Slowik A, Slowik J (2008) Multi-objective optimization of surface grinding process with the use of evolutionary algorithm with remembered Pareto set. Int J Adv Manuf Technol 37(7-8):657–669

Pawar PJ, Rao RV, Davim JP (2010) Multiobjective optimization of grinding process parameters using particle swarm optimization algorithm. Mater Manuf Process 25(6):424–431

Rao RV, Pawar PJ (2010) Grinding process parameter optimization using non-traditional optimization algorithms. Proc Inst Mech Eng B J Eng Manuf 224(6):887–898

Pawar PJ, Rao RV (2013) Parameter optimization of machining processes using teaching–learning-based optimization algorithm. Int J Adv Manuf Technol 67(5-8):995–1006

Huang J, Gao L, Li X (2015) An effective teaching-learning-based cuckoo search algorithm for parameter optimization problems in structure designing and machining processes. Appl Soft Comput 36:349–356

Krasnogor N, Smith J (2005) A tutorial for competent memetic algorithms: model, taxonomy and design issues. IEEE Trans Evol Comput 9(5):474–488

Vaz AIF, Vicente LN (2007) A particle swarm pattern search method for bound constrained global optimization. J Glob Optim 39(2):197–219

Kang F, Junjie LJ, Li H (2013) Artificial bee colony algorithm and pattern search hybridized for global optimization. Appl Soft Comput 13:1781–1791

Xing F, Masson R, Lopez S (2017) Parallel vertex approximate gradient discretization of hybrid dimensional Darcy flow and transport in discrete fracture networks. Comput Geosci 21(4):595–617

Ahrari A, Atai AA, Deb K (2015) Simultaneous topology, shape and size optimization of truss structures by fully stressed design based on evolution strategy. Eng Optim 47(8):1063–1084

Xu S, Wang Y, Wang Z (2019) Parameter estimation of proton exchange membrane fuel cells using eagle strategy based on JAYA algorithm and Nelder-Mead simplex method. Energy 173:457–467

Rajan A, Malakar T (2015) Optimal reactive power dispatch using hybrid Nelder–Mead simplex based firefly algorithm. Int J Electr Power Energy Syst 66:9–24

Liu B, Wang L, Jin YH (2007) An effective PSO-based memetic algorithm for flow shop scheduling. IEEE Transactions on Systems, Man, and Cybernetics, Part B (Cybernetics) 37(1):18–27

Sarakhsi MK, Ghomi SMTF, Karimi B (2016) A new hybrid algorithm of scatter search and Nelder–Mead algorithms to optimize joint economic lot sizing problem. J Comput Appl Math 292:387–401

Assimi H, Jamali A (2018) A hybrid algorithm coupling genetic programming and Nelder–Mead for topology and size optimization of trusses with static and dynamic constraints. Expert Syst Appl 95:127–141

Moezi SA, Zakeri E, Zare A (2018) Structural single and multiple crack detection in cantilever beams using a hybrid Cuckoo-Nelder-Mead optimization method, Mechanical Systems and Signal Processing 99 (2018) 805–831.

Nelder JA, Mead R (1965) A simplex method for function minimization. Comput J 7(4):308–313

Sadollah A, Bahreininejad A, Eskandar H, Hamdi M (2013) Mine blast algorithm: a new population based algorithm for solving constrained engineering optimization problems. Appl Soft Comput 13:2592–2612

Yıldız AR, Kurtuluş E, Demirci E, Yıldız BS, Karagöz S (2016) Optimization of thin-wall structures using hybrid gravitational search and Nelder-Mead algorithm. Materials Testing 58(1):75–78

Gandomi AH, Yang X-S, Alavi AH (2013) Cuckoo search algorithm: a meta- heuristic approach to solve structural optimization problems. Eng Comput 29:17–35

Cheng M-Y, Prayogo D (2014) Symbiotic organisms search: a new metaheuristic optimization algorithm. Comput Struct 139:98–112

Chickermane H, Gea H (1996) Structural optimization using a new local approximation method. Int J Numer Methods Eng 39:829–846

Carlos A, Coello C (2000) Constraint-handling using an evolutionary multiobjective optimization technique. Civil Eng Syst 17:319–346

Ragsdell K, Phillips D (1976) Optimal design of a class of welded structures using geometric programming. ASME J Eng Ind 98:1021–1025

Coello Coello CA (2002) Theoretical and numerical constraint-handling techniques used with evolutionary algorithms: a survey of the state of the art. Comput Methods Appl Mech Eng 191:1245–1287

Coello Coello CA, Mezura ME (2002) Constraint-handling in genetic algorithms through the use of dominance-based tournament selection. Adv Eng Inform 16:193–203

Siddall JN (1972) Analytical decision-making in engineering design. Prentice-Hall, Englewood Cliffs, NJ

Zhang M, Luo W, Wang X (2008) Differential evolution with dynamic stochastic selection for constrained optimization. Inf Sci 178:3043–3074

Liu H, Cai Z, Wang Y (2010) Hybridizing particle swarm optimization with differential evolution for constrained numerical and engineering optimization. Appl Soft Comput 10:629–640

Tsai J-F (2005) Global optimization of nonlinear fractional programming problems in engineering design. Eng Optim 37:399–409

Ray T, Saini P (2001) Engineering design optimization using a swarm with an intelligent information sharing among individuals. Eng Optim 33:735–748

Khalilpourazari S, Khalilpourazary S (2018) A robust stochastic fractal search approach for optimization of the surface grinding process. Swarm Evol Comput 38:173–186

Deb K (2000) An efficient constraint handling method for genetic algorithms. Comput Method Appl Mech Eng 186:311–338

He Q, Wang L (2007) An effective co-evolutionary particle swarm optimization for constrained engineering design problems. Eng Appl Artif Intell 20:89–99

Wang GG (2003) Adaptive response surface method using inherited latin hypercube design points. J Mech Des 125:210–220

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1

Appendix 1

1.1. Three-bar truss problem

The problem can be mathematically formulated as follows:

Minimize: \( f(x)=\left(2\sqrt{2{A}_1}+{A}_2\right)\times l \)

Subject to:

where 0 ≤ A1 ≤ 1, 0 ≤ A2 ≤ 1, l = 100 cm, P = 2kN, σ = 2kN/cm2

1.2. Cantilever problem

The problem can be mathematically formulated as follows:

Minimize :

Subject to:

The design variables are the heights (or widths) of the different beam elements, and the thickness is held fixed (here t = 2/3). The bound constraints are set as 0.01 ≤ xj ≤ 100. This problem can be expressed analytically as follows:

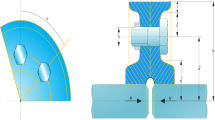

1.3. Welded beam design problem

The problem can be mathematically formulated as follows:

Minimize: f(x) = 1.10471h2l + 0.04811tb(14.0 + l)

Subject to:

where \( \tau =\sqrt{{\left({\tau}^{\prime}\right)}^2+{\left({\tau}^{\prime \prime}\right)}^2+2{\tau}^{\prime }{\tau}^{\prime \prime}\frac{l}{2R}},\kern0.75em {\tau}^{\prime }=\frac{P}{\sqrt{2} hl},\kern0.75em {\tau}^{\prime \prime }=\frac{MR}{J},M=P\left(L+\frac{1}{2}\right),R=\sqrt{\frac{l^2}{4}+\frac{{\left(h+t\right)}^2}{4}} \)

and 1 ≤ l, t ≤ 10.

Rights and permissions

About this article

Cite this article

Yildiz, A.R. A novel hybrid whale–Nelder–Mead algorithm for optimization of design and manufacturing problems. Int J Adv Manuf Technol 105, 5091–5104 (2019). https://doi.org/10.1007/s00170-019-04532-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04532-1