Abstract

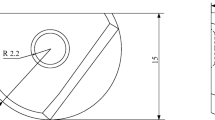

Titanium alloys is a typical difficult-to-cut material with many machining problems, build-up-edge, large cutting force, and high cutting heat. Previous research has shown that micro-texture on the tool surface can solve the above problems potentially, and that a blunt round edge of the cutting tool can enhance its strength and improve the tool wear resistance. Therefore, towards an optimal parameter of micro-texture and blunt round radius, a finite element method (FEM) simulation and an experiment are carried out, where the test result provides a set of data for a genetic algorithm–based prediction model. The optimized parameter combinations of the micro-textured ball-end milling cutter with a blunt round edge are obtained and compared in a set of experiments. The optimized parameters refer to a 40-μm radius of the blunt round edge, a 40-μm micro-texture diameter, a 175-μm spacing, a 120-μm distance from the cutting edge, and an 80-μm depth.

Similar content being viewed by others

References

Wang HY, Guo ZM, Lu BX, Zhang C (2017) Industrialized production technology of powder metallurgy (PM) titanium and titanium alloy. Titan Ind Prog 34(01):1–5

Fei YJ (2017) Application of titanium and titanium alloy materials. Adv Mater Ind 03(05):15–18

Qi BY (2011) Research on cooling/lubrication technology of green cutting of titanium alloy using surface micro-texture cutting tool. Nanjing University of Aeronautics and Astronautics, The Graduate School, Nanjing, pp 12–14

Zheng WJ, Huang Q, Zhao XF, Zhou YB (2014) Finite element analysis on influence of rounded cutting edge radius of milling cutter to cutting property. Coal Mine Mach 35(10):125–127

Yang S, Tong X, Liu XL, Ji W, Zhang YH (2018) Investigation on the characteristic of forces of the tool edge in finish machining of titanium alloys. Int J Adv Manuf Technol 96:2431–2441

Obikawa T, Kamio A, Takaoka H, Osada A (2011) Micro-texture at the coated tool face for high performance cutting. Int J Mach Tools Manuf 51:966–972

Wan QF, Lei YY, Yang H, Tao H (2014) Finite element analysis of tool edge roundness based on ABAQUS. J Xihua Univ Nat Sci 33(02):63–66

Cao ZY (2008) Fundamental research on machine tool, cutting tool and cutting mechanism for micro-milling. Nanjing University of Aeronautics and Astronautics, The Graduate School, Nanjing, pp 59–86

Ezugwu EO, Bonney J, Da Silva RB, Çakir O (2007) Surface integrity of finished turned Ti-6Al-4V alloy with PCD tools using conventional and high pressure coolant supplies. Int J Mach Tools Manuf 47:884–891

Kawasegi N, Sugimori H, Morimoto H, Morita N, Hori M (2009) Development of cutting tools with microscale and nanoscale textures to improve frictional behavior. Precis Eng 33:248–254

Wu YX (1983) The role of the radius of the cutting edge in micro-cutting. Proc Equip 01:1–5

She XR, Su M, LingHu KJ (2015) Influence of cutting parameters and rounded edge radius on milling temperature of 45 steel. Mod Manuf Proc Equip 05:22–25

Wu Z, Deng JX, Lian YS, Cheng HW, Yan GY (2012) Development and perspective of surface textured cutting tool. Aeronaut Manuf Tech 10:32–37

Enomoto T, Sugihara T (2010) Improving anti-adhesive properties of cutting tool surfaces by nano-/micro-textures. CIRP Ann - Manuf Technol 59:597–600

Enomoto T, Sugihara T (2011) Improvement of anti-adhesive properties of cutting tool by nano/micro textures and its mechanism. Procedia Eng 19:100–105

Enomoto T, Sugihara T, Yukinaga S, Yukinaga S, Satak U (2012) Highly wear-resistant cutting tools with textured surfaces in steel cutting. CIRP Ann - Manuf Technol 61:571–574

Sugihara T, Enomoto T (2013) Crater and flank wear resistance of cutting tools having micro surfaces. Precis Eng 37:888–896

Sugihara T, Enomoto T (2012) Improving anti-adhesion in aluminum alloy cutting by micro stripe texture. Precis Eng 36:229–237

Koshy P, Tovey J (2011) Performance of electrical discharge textured cutting tools. CIRP Ann - Manuf Technol 60:153–156

Wu KZ, Chen YJ, Zhu DD, Chen DH, Zhou FQ, Zheng W (2005) Application of friction-reducing groove on insert with 3D chip-breaking groove. Tool Eng 39(5):53–55

Yin SB, Ji W, He GH, Liu XL, Wang LH (2018) Experimental evaluation on texture of flank face on tool wear in chamfer milling of stainless steel. Int J Adv Manuf Technol 99:2929–2937

Yang SC, Liu WW, Zhang YH, Wan Q (2018) Experimental evaluation on micro-texture parameters of carbide ball-nosed end mill in machining of titanium alloy. Int J Adv Manuf Technol 96:1579–1589

Li Q, Yang SC, Zhang YH, Zhou YZ, Cui JT (2018) Evaluation of the machinability of titanium alloy using a micro-textured ball end milling cutter. Int J Adv Manuf Technol 98:2083–2092

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, S., Ren, W., Wang, T. et al. Parameter optimization of a micro-textured ball-end milling cutter with blunt round edge. Int J Adv Manuf Technol 106, 577–588 (2020). https://doi.org/10.1007/s00170-019-04499-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04499-z