Abstract

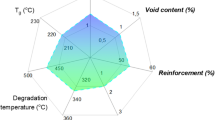

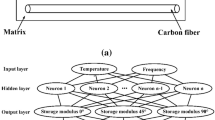

A considerable interest has been generated in recent years in the use of thermoplastic polymers as matrices in the manufacture of advanced composites that require high reliability during long-term operations. In this research, a new Elium® acrylic matrix developed by Arkema was studied to evaluate the accelerated test methodology based on time-temperature superposition principle of Carbon Fiber/Elium® 150 composites. The results show that the high frequencies increase the glass transition (Tg) to higher values because the free volume is favored by polymer chains movement. In addition, artificial neural network has been used to model the temperature-frequency dependence of dynamic mechanical over the wide range of temperatures and frequencies due to its complex non-linear behavior. It has been observed that low frequencies result in low damping due to the lower internal friction, while high frequencies provide greater stiffness to the chains, resulting in a high damping. The long-term life prediction using master curves confirms that this new material can be considered to acoustic or vibrational damping purposes, considering its use in temperatures above Tg.

Similar content being viewed by others

References

Rezende MC, Costa ML, Botelho EC (2011) Compósitos estruturais: tecnologia e prática. São Paulo, Artlibre Editora, 396p

Marshall AC (1987) Composite structures in homebuilt sport aircraft. In: International sample symposium and exhibition, 32. Tokyo. Proceedings. Covina: SAMPE, 1510-1518 .

Ferry JA (1980) Viscoelastic properties of polymers, 3rd edn. John Wiley, New York, 672p

Menard KP (2008) Dynamic mechanical analysis: a practical introduction. CRC press

ARKEMA. Elium®150 Technical Datasheet. Arkema Inovative Chemistry. [S.I]. 2014

Cândido GM, Donadon MV, Almeida SFM, Rezende MC (2014) Fractografia de Compósito Estrutural Aeronáutico Submetido ao Ensaio de Tenacidade à Fratura Interlaminar em Modo II. Polim.: Cienc Tecnol 24:65–71

Feng J, Guo Z (2016) Temperature-frequency-dependent mechanical properties model of epoxy resin and its composites. Composites: Part B 85:161–169

Rouleau L, Deu JF, Legay A, Le Lay F (2013) Application of Kramers–Kronig relations to time–temperature superposition for viscoelastic materials. Mech. Mater 65:66–75

Cassu SN, Felisberti MI (2005) Comportamento dinâmico-mecânico e relaxações em polímeros e blendas poliméricas. Quim. Nova 28(2):255–263

Williams ML, Landel RF, Ferry JD (1955) The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J. Amer. Chem. Soc. 77:3701

Zhang Z, Friedrich K (2003) Artificial neural networks applied to polymer composites: a review. Compos Sci and technol 63:2029–2044

Idicula M, Malhotra SK, Joseph K, Thomas S (2005) Dynamic mechanical analysis of randomly oriented intimately mixed short banana/sisal hybrid fibre reinforced polyester composites. Compos Sci Technol 65:1077–1087

Goh ATC (1995) Back-propagation neural networks for modeling complex systems. Artificial Intelligence in Engineering 9:143–151

Yang HJ, Roe BP, Zhu J (2007) Studies of stability and robustness for artificial neural networks and boosted decision trees, Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers. Detectors and Associated Equipment 574(2):342–349

Xu X, Gupta N (2019) Artificial neural network approach to predict the elastic modulus from dynamic mechanical analysis results. Adv Theory Simul 2:1800131

Zhang Z, Klein P, Friedrich K (2002) Dynamic mechanical properties of PTFE based short carbon fibre reinforced composites: experiment and artificial neural network prediction. Compos Sci and Technol 62(7-8):1001–1009

Kopal I, Harničárová M, Valíček J, Kušnerová M (2017) Modeling the temperature Dependence of dynamic mechanical properties and visco-elastic behavior of thermoplastic polyurethane using artificial neural network. Polymers 9:519

Altinkok N (2006) Use of artificial neural network for prediction of mechanical properties of α-Al2O3 particulate-reinforced Al–Si10Mg alloy composites prepared by using stir casting process. Journal of Composite Materials 40(9):779–796

Farhanaa N.I.E, Abdul Majida M.S., Paulraja M.P., Ahmadhilmib E., Fakhzana M.N., Gibson A.G. A novel vibration based non-destructive testing for predicting glassfibre/matrix volume fraction in composites using a neural networkmodel. Composites structures, 2016, 144, 96-107.

Ihesiulor OK, Shankar K, Zhang Z, Ray T (2014) Delamination detection with error and noise polluted natural frequencies using computational intelligence concepts. Composites Part B: Engineering 56:906–925

Ravi Sankar H, Srikant RR, Vamsi Krishna P, Bhujanga Rao V, Bangaru Babu P (2013) Estimation of the dynamic properties of epoxy glass fabric composites with natural rubber particle inclusions. International Journal of Automotive and Mechanical Engineering (IJAME) 7:968–980

Burgaz E, Yazici M, Kapusuz M, Alisir SH (2014) Hakan Ozcanb Prediction of thermal stability, crystallinity and thermomechanical properties of poly(ethylene oxide)/clay nanocomposites with artificial neural networks. Thermochimica Acta 575:159–166

Ang JY, Abdul Majid MS, Mohd NA, Yaacob S, Ridzuan MJM (2018) First-ply failure prediction of glass/epoxy composite pipes using an artificial neural network model. Composites structures 200:579–588

Zhang Z, Shankar K, Ray T, Morozov EV, Tahtali M (2013) Vibration-based inverse algorithms for detection of delamination in composites. Compos Struct 102:226–236

Chen L, Chiu TC, Chen TC, Chung MH, Yang PF, Lai YS (2014) Using DMA to simultaneously acquire Young's relaxation modulus and time-dependent Poisson's ratio of a viscoelastic material. Procedia Eng. 79:153–159

Boyer RF (1968) Dependence of mechanical properties on molecular motion in polymers. Polym. Eng. Sci. 8:161

Raponi OA, Barbosa LCM, Souza BR, Junior ACA (2018) Study of the influence of initiator content in the polymerization reaction of a thermoplastic liquid resin for advanced composite manufacturing. Adv Polym Technol. 37:3579–3587

Oysaed H (1990) Dynamic mechanical properties of multiphase acrylic systems. J. Biomed. Mater. Res. 24:1037–1048

Heijboer J (1977) Secondary loss peaks in glassy amorphous polymers. J. Polym. Mater. 6:11–37

Pothan LA, Oommen Z, Thomas S (2003) Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compos Sci Technol 63(2):283–293

Rana D, Mounach H, Halary JL et al (2005) J. Differences in mechanical behavior between alternating and random styrene-methyl methacrylate copolymers. Mater Sci 40:943

Acknowledgments

The authors are grateful to the Brazilian Funding Institutions FINEP (Financier of Studies and projects), CAPES (Improvement Coordination of Higher Level Personnel), and FAPEMIG (research supporting foundation of Minas Gerais state—Grant number APQ-00385-18) for the financial supports.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Barbosa, L.C.M., Gomes, G. & Junior, A.C.A. Prediction of temperature-frequency-dependent mechanical properties of composites based on thermoplastic liquid resin reinforced with carbon fibers using artificial neural networks. Int J Adv Manuf Technol 105, 2543–2556 (2019). https://doi.org/10.1007/s00170-019-04486-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04486-4