Abstract

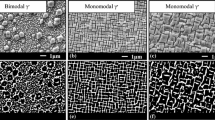

Nickel-based superalloys are used for turbine component parts in the power industry, aircraft engines, and in the marine sector. One such alloy that is available for these purposes is Inconel 738LC (IN738LC) nickel-based superalloy. Therefore, it is pertinent to have good structural and thermal stabilities for high-temperature applications, since these characteristics are important for its performance. In this study, spark plasma sintering technology was used to fabricate IN738LC nickel-based superalloy by using sintering temperature in the range of between 900 and 1200 °C. The fabricated products were characterized by using the scanning electron microscope and X-ray diffraction. There was the formation of the γ′(Ni3(Ti, Aℓ)) intermetallic phase in the microstructure, which contributed to the material (Inconel 738LC) property. The solid solution elements present are chromium, cobalt, tungsten, and tantalum; these equally contribute to the structural stability of IN738LC. The density, hardness, and the predicted yield strength increased with increasing sintering temperature, while the porosity decreased with increasing sintering temperature. The thermal conductivity, which is an important thermophysical property of IN738LC, enables the evaluation of the usefulness and service life of IN738LC superalloy at high-temperature applications, was also examined. The thermal conductivity was measured by using a laser flash method in the temperature range of 100–600 °C. For the sintered alloy, the thermal conductivity was determined as a function of the thermal diffusivity, specific heat capacity, and density. Analysis showed inflection pattern with increase in temperature on the sample fabricated at 900, 1000, and 1100 °C, ; a monotonic increase with increase in temperature was observed on the sample fabricated at 1200°C, ; the inflections are associated with the γ′ precipitates dissolution and redistribution.

Similar content being viewed by others

References

Rai AK, Trpathy H, Hajra R, Raju S, Saroja S (2017) Thermophysical properties of Ni based super alloy 617. J Alloys Compd 698:442–450

Balikci E, Raman A (2000) Characteristics of the γ′ precipitates at high temperatures in Ni-base polycrystalline superalloy IN738LC. J Mater Sci 35:3593–3597

Suwardie JH, Artiaga R, Mier JL (2002) Thermal characterization of a Ni-based superalloy. Thermochim Acta 392:295–298

Bugge J, Kjaer S, Blum R (2006) High-efficiency coal-fired power plants development and perspectives. Energy 31:1437–1445

Bogner S, Ivanova E, Müller M, Wang F, Ma D, Bührig-Polaczek A (2015) Investigation of the Undercoolability of Ni-based alloys using high temperature thermal analysis. Metals 5:1971–1983

Mills KC, Youssef YM, Li Z, Su Y (2006) Calculation of thermophysical properties of Ni-based superalloys. ISIJ Int 46:623–632

Mirjavadi SS, Alipour M, Hamouda A, Givi MB, Emamy M (2014) Investigation of the effect of Al-8B master alloy and strain-induced melt activation process on dry sliding wear behavior of an Al–Zn–mg–cu alloy. Mater Des 53:308–316

Afshari BM, Mirjavadi SS, Dolatabad YA, Aghajani M, Givi MKB, Alipour M et al (2016) Effects of pre-deformation on microstructure and tensile properties of Al—Zn—mg—cu alloy produced by modified strain induced melt activation. Trans Nonferrous Metals Soc China 26:2283–2295

Matysiak H, Zagorska M, Andersson J, Balkowiec A, Cygan R, Rasinski M, Pisarek M, Andrzejczuk M, Kubiak K, Kurzydlowski K (2013) Microstructure of Haynes® 282® superalloy after vacuum induction melting and investment casting of thin-walled components. Materials 6:5016–5037

Zupanič F, Bončina T, Križman A, Tichelaar F (2001) Structure of continuously cast Ni-based superalloy Inconel 713C. J Alloys Compd 329:290–297

Xu X, Ward R, Jacobs M, Lee P, McLean M (2002) Tree-ring formation during vacuum arc remelting of INCONEL 718: part I. experimental investigation. Metall Mater Trans A 33:1795–1804

Mirjavadi SS, Alipour M, Hamouda A, Matin A, Kord S, Afshari BM et al (2017) Effect of multi-pass friction stir processing on the microstructure, mechanical and wear properties of AA5083/ZrO2 nanocomposites. J Alloys Compd 726:1262–1273

Hoseinlaghab S, Mirjavadi SS, Sadeghian N, Jalili I, Azarbarmas M, Givi MKB (2015) Influences of welding parameters on the quality and creep properties of friction stir welded polyethylene plates. Mater Des 67:369–378

Mirjavadi SS, Alipour M, Emamian S, Kord S, Hamouda A, Koppad PG et al (2017) Influence of TiO2 nanoparticles incorporation to friction stir welded 5083 aluminum alloy on the microstructure, mechanical properties and wear resistance. J Alloys Compd 712:795–803

Ghosh N, Harimkar S (2012) Consolidation and synthesis of MAX phases by spark plasma sintering (SPS): a review. In: Advances in science and Technology of Mn+ 1axn phases. Elsevier, pp 47–80

Diouf S, Molinari A (2012) Densification mechanisms in spark plasma sintering: effect of particle size and pressure. Powder Technol 221:220–227

Ma S, Yang Y, Li A, Zhou S, Shi L, Wang S, Liu M (2018) Effects of temperature on microstructure and mechanical properties of IN718 reinforced by reduced graphene oxide through spark plasma sintering. J Alloys Compd 767:675–681

Zieliñska M, Yavorska M, Porêba M, Sieniawski J (2010) Thermal properties of cast nickel based superalloys. Arch Mater Sci Eng 44:35–38

Terada Y, Ohkubo K, Miura S, Sanchez JM, Mohri T (2003) Thermal conductivity and thermal expansion of Ir3X (X= Ti, Zr, Hf, V, Nb, ta) compounds for high-temperature applications. Mater Chem Phys 80:385–390

Akoshima M, Tanaka T, Endo S, Baba T, Harada Y, Kojima Y, Kawasaki A, Ono F (2011) Thermal diffusivity measurement for thermal spray coating attached to substrate using laser flash method. Jpn J Appl Phys 50:11RE01

Loshchinin YV, Folomeikin YI, Pakhomkin S (2016) A study of the heat capacity of coated metal materials by the laser flash method. Inorg Mater 52:1478–1482

Rani S, Agrawal AK, Rastogi V (2017) Failure analysis of a first stage IN738 gas turbine blade tip cracking IN a thermal power plant. Case Stud Eng Fail Anal 8:1–10

Pérez-González F, Garza-Montes-de Oca N, Colás R (2014) High temperature oxidation of the Haynes 282© nickel-based superalloy. Oxid Met 82:145–161

Osada T, Gu Y, Nagashima N, Yuan Y, Yokokawa T, Harada H (2013) Optimum microstructure combination for maximizing tensile strength in a polycrystalline superalloy with a two-phase structure. Acta Mater 61:1820–1829

Osada T, Gu YF, Nagashima N, Yuan Y, Yokokawa T, Harada H (2012) New quantitative analysis of contributing factors to strength of disk SUPERALLOYS. John Wiley & Sons, Chichester

Technical Data – NiPERA. One New York plaza, New York, NY, 10004

IN-738 Alloy - Preliminary Data (497) - Nickel Institute. One new york plaza, New York, NY, 10004

Min S, Blumm J, Lindemann A (2007) A new laser flash system for measurement of the thermophysical properties. Thermochim Acta 455:46–49

Furrer D, Fecht H (1999) Ni-based superalloys for turbine discs. Jom 51:14–17

Vervoort P, Vetter R, Duszczyk J (1996) Overview of powder injection molding. Adv Perform Mater 3:121–151

Wikstrom N, Ojo O, Chaturvedi M (2006) Influence of process parameters on microstructure of transient liquid phase bonded Inconel 738LC superalloy with Amdry DF-3 interlayer. Mater Sci Eng A 417:299–306

Jalilvand V, Omidvar H, Shakeri H, Rahimipour M (2013) Microstructural evolution during transient liquid phase bonding of Inconel 738LC using AMS 4777 filler alloy. Mater Charact 75:20–28

Zhen J, Li F, Zhu S, Ma J, Qiao Z, Liu W, Yang J (2014) Friction and wear behavior of nickel-alloy-based high temperature self-lubricating composites against Si3N4 and Inconel 718. Tribol Int 75:1–9

Özgün Ö, Gülsoy HÖ, Yılmaz R, Fındık F (2013) Microstructural and mechanical characterization of injection molded 718 superalloy powders. J Alloys Compd 576:140–153

Sarkar A, Mukherjee P, Barat P, Jayakumar T, Mahadevan S, Rai SK (2008) Lattice misfit measurement in Inconel 625 by X-ray diffraction technique. Int J Modern Phys B 22:3977–3985

Eze AA, Jamiru T, Sadiku ER, Durowoju MỌ, Kupolati WK, Ibrahim ID, Obadele BA, Olubambi PA, Diouf S (2018) Effect of titanium addition on the microstructure, electrical conductivity and mechanical properties of copper by using SPS for the preparation of cu-Ti alloys. J Alloys Compd 736:163–171

Khouzani MK, Bahrami A, Mehr MY (2019) Spark plasma sintering of Stellite®-6 superalloy. J Alloys Compd 782:461–468

García JMJ, Li Z, Vahlas C, de La Torre SD, López FJ (2010) Spark plasma sintering and characterization of NiCoCrAlY-Ta superalloy powder. J Mater Sci Eng 4:57–63

Yang L, Chang K-M, Mannan S, deBarbadillo J (1997) A new DTA approach for verifying precipitate solvus in Inconel alloy 718. Superalloys 718, 625, 706and various derivatives:353–365

Yang L, Chang K-M, Mannan S, deBarbadillo J (1997) A new DTA approach for verifying precipitate solvus in Inconel alloy 718(differential thermal analysis). Superalloys 718, 625, 706 and various derivatives:353–365

Klemens P, Williams R (1986) Thermal conductivity of metals and alloys. Int Metals Rev 31:197–215

Rao K, Åström H, Johannesson C (1972) Magnetic contribution to thermal conductivity of neodymium. Phys Lett A 42:53–55

Korenblit IY, Lazarenko YP (1971) Thermal emf and thermal resistance of ferromagnetic metals with impurities. Sov Phys Jetp 33:837–842

Murashov V, White M, Tritt T (2004) Thermal conductivity: theory, properties, and applications. Kluwer Academic/Plenum Publishers, New York

Funding

This work is funded by the Research and Innovation Directorate of Tshwane University of Technology and supported, in part, by the Department of Mechanical Engineering, Mechatronics and Industrial Design, Institute for NanoEngineering Research (INER), Department of Chemical, Metallurgical and Materials Engineering and the Faculty of Engineering and Built Environment of the Tshwane University of Technology, Pretoria, South Africa.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ogunbiyi, O.F., Jamiru, T., Sadiku, E.R. et al. Microstructural characteristics and thermophysical properties of spark plasma sintered Inconel 738LC. Int J Adv Manuf Technol 104, 1425–1436 (2019). https://doi.org/10.1007/s00170-019-03983-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03983-w