Abstract

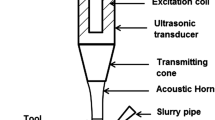

In this study, the mechanism design and analysis of free and forced vibrations of vibrating tool in ultrasonic assisted surface rolling process (UASR) were taken into consideration. In this regard, three free vibrations problems are studied: first, a simple five-element horn with cylindrical-conical geometry; second, an UASR horn with complex geometrical shape; and third, an integrated UASR system, including transducer and booster (made earlier) associated with UASR horn. Moreover, their natural frequency, mode shape, and amplification factor were achieved individually. UASR system is experimentally manufactured and its oscillations amplitudes are extracted for different forced excitation frequencies. It was observed that the empirical resonance frequency was more consistent with the numerical results of UASR system than UASR horn, while the latter has been used for ultrasonic analyses and designing till now. Considering appropriate damping, numerical harmonic analysis of UASR horn was performed to extract the vibrational behavior of its end involved and not involved with the workpiece, whereas an external oscillatory force excites the primary section of the UASR horn. The loading history on the workpiece surface and fluctuations amplitude of the involved horn end were extracted, where their experimental measurement was impossible. In both cases, maximum mechanical oscillations of the horn end were observed at forced excitation with the same natural frequency obtained in numerical modal analysis, which is due to resonance occurrence and standing wave formation at the horn.

Similar content being viewed by others

References

Lucas M (1996) Vibration sensitivity in the design of ultrasonic forming dies. Ultrasonics 34(1):35–41

Yadava V, Deoghare A (2008) Design of horn for rotary ultrasonic machining using the finite element method. Int J Adv Manuf Technol 39(1):9–20

Amini S, Soleimanimehr H, Nategh MJ, Abudollah A, Sadeghi MH (2008) FEM analysis of ultrasonic-vibration-assisted turning and the vibratory tool. J Mater Process Technol 201(1):43–47

Roopa Rani M, Rudramoorthy R (2013) Computational modeling and experimental studies of the dynamic performance of ultrasonic horn profiles used in plastic welding. Ultrasonics 53(3):763–772

Suh C-M, Song G-H, Suh M-S, Pyoun Y-S (2007) Fatigue and mechanical characteristics of nano-structured tool steel by ultrasonic cold forging technology. Mater Sci Eng A 443(1):101–106

Cao XJ, Pyoun YS, Murakami R (2010) Fatigue properties of a S45C steel subjected to ultrasonic nanocrystal surface modification. Appl Surf Sci 256(21):6297–6303

Cherif A, Pyoun Y, Scholtes B (2010) Effects of ultrasonic nanocrystal surface modification (UNSM) on residual stress state and fatigue strength of AISI 304. J Mater Eng Perform 19(2):282–286

Banks HT, Inman DJ (1991) On damping mechanisms in beams. J Appl Mech 58(3):716–723

Abdullah A, Malaki M (2013) On the damping of ultrasonic transducersʼ components. Aerosp Sci Technol 28(1):31–39

Saleem A, Salah M, Ahmad N, Silberschmidt V (2013) Control of ultrasonic transducers for machining applications. In: 2013 9th International Symposium on Mechatronics and its Applications (ISMA), 9–11 April 2013. pp 1–5

Sun K, Mou S, Qiu J, Wang T, Gao H (2018) Adaptive fuzzy control for non-triangular structural stochastic switched nonlinear systems with full state constraints. IEEE Trans Fuzzy Syst https://doi.org/10.1109/TFUZZ.2018.2883374

Long Z, Zou J, Zhao S, Sun W, Sun Z (2016) Numerical modeling and vibration control of transducer in ultrasonically assisted machining. In: 2016 symposium on piezoelectricity, acoustic waves, and device applications (SPAWDA), 21–24 Oct. 2016. pp 283–287

Babitsky VI, Astashev VK, Kalashnikov AN (2004) Autoresonant control of nonlinear mode in ultrasonic transducer for machining applications. Ultrasonics 42(1):29–35

Razavi H, Mirbagheri M (2016) Design and fabrication of a novel vibrational system for ultrasonic assisted oblique turning process. J Mech Sci Technol 30(2):827–835

Milan N (2010) Ultrasonic horn design for ultrasonic machining technologies. Appl and Comput Mech 4(1)

Ensminger D, Leonard JB (2011) Ultrasonics: fundamentals, technologies, and applications, 3rd edn. CRC Press, Boca Raton

Bängtsson E, Noreland D, Berggren M (2003) Shape optimization of an acoustic horn. Comput Methods Appl Mech Eng 192(11):1533–1571

Tolga Bozdana A, Gindy NNZ, Li H (2005) Deep cold rolling with ultrasonic vibrations—a new mechanical surface enhancement technique. Int J Mach Tools Manuf 45(6):713–718

Al-Budairi HD (2012) Design and analysis of ultrasonic horns operating in longitudinal and torsional vibration. University of Glasgow, Glasgow

Amin SG, Ahmed MHM, Youssef HA (1995) Computer-aided design of acoustic horns for ultrasonic machining using finite-element analysis. J Mater Process Technol 55(3):254–260

Razavi H, Nategh MJ, Abdullah A (2012) Analytical modeling and experimental investigation of ultrasonic-vibration assisted oblique turning, part III: experimental investigation. Int J Mech Sci 63(1):26–36

Hale S (2010) Damping in ANSYS/LS-Dyna. CAE Associations 2:77–84

Daud Y, Lucas M, Huang Z (2007) Modelling the effects of superimposed ultrasonic vibrations on tension and compression tests of aluminium. J Mater Process Technol 186(1):179–190

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Razavi, H., Keymanesh, M. & Golpayegani, I.F. Analysis of free and forced vibrations of ultrasonic vibrating tools, case study: ultrasonic assisted surface rolling process. Int J Adv Manuf Technol 103, 2725–2737 (2019). https://doi.org/10.1007/s00170-019-03718-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03718-x