Abstract

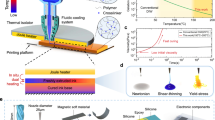

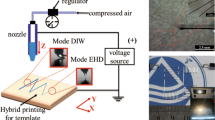

Low-cost manufacturing technology for a micro-sized structure is receiving a lot of attention as human society is getting mixed with sensors and electronics. A template printing technology which forms micro-patterns by letting ink dried within a solvent permeable template is an attractive alternative of traditional costly micro-fabrication. However, low printing speed and lack of scalability have been recognized as a major drawback of this method. Here, we propose a novel printing machine using an inflatable polymer template. It is expected that thin membrane improves the printing speed due to its high permeation speed; however, the theoretical prediction and experimental proof of this approach has not been studied. A 450-μm thick membrane is fabricated by the casting polydimethylsiloxane (PDMS) on a silicon master mold, fixed to a printer head, and inflated to contact with substrate uniformly. The permeation mechanism is investigated by using both of the numerical simulation and experiments and discovers that the diffusion in thin membrane obeys an analytical solution for Fick’s diffusion in steady state, while a conventional bulk template (10 mm) is in non-steady state. The printing system composed of pneumatic lines, a flash sintering unit, and a printer head holds the membrane is prototyped to ensure reproducibility of this novel method, five times faster printing speed compared to the ordinal method is confirmed.

Similar content being viewed by others

References

Gates BD, Xu Q, Stewart M, Ryan D, Willson CG, Whitesides GM (2005) New approaches to nanofabrication: molding, printing, and other techniques. Chem Rev 105(4):1171–1196

Geissler M, Xia Y (2004) Patterning: principles and some new developments. Adv Mater 16(15):1249–1269

Khan S, Lorenzelli L, Dahiya RS (2015) Technologies for printing sensors and electronics over large flexible substrates: a review. IEEE Sens J 15(6):3164–3185

Saengchairat N, Tran T, Chua C-K (2017) A review: additive manufacturing for active electronic components. Virtual Phys Prototyp 12(1):31–46

Calvert P (2001) Inkjet printing for materials and devices. Chem Mater 13(10):3299–3305

de Gans B, Duineveld P, Schubert U (2004) Inkjet printing of polymers: state of the art and future developments. Adv Mater 16(3):203–213

Park J-U, Hardy M, Kang SJ, Barton K, Adair K, kishore Mukhopadhyay D, Lee CY, Strano MS, Alleyne AG, Georgiadis JG, Ferreira PM, Rogers JA (2007) High-resolution electrohydrodynamic jet printing. Nat. Mater. 6:782

Onses MS, Sutanto E, Ferreira PM, Alleyne AG, Rogers JA (2015) Mechanisms, capabilities, and applications of high resolution electrohydrodynamic jet printing. Small 11(34):4237–4266

Vaezi M, Seitz H, Yang S (2013) A review on 3D micro-additive manufacturing technologies. Int J Adv Manuf Technol 67(5):1721–1754

Wan AB, Kukjoo K, Heejoo L, So-Yun K, Yulhui S, Dae-Young L, Yeob SJ, Jang Ung P (2015) High-resolution printing of 3D structures using an electrohydrodynamic inkjet with multiple functional inks. Adv Mater 27(29):4322–4328

Gerber M, Beddingfield C, O’Connor S, Yoo M, Lee M, Kang D, Park S, Zwenger C, Darveaux R, Lanzone R, Park K (2011) Next generation fine pitch Cu Pillar technology - enabling next generation silicon nodes. In: 2011 IEEE 61st electronic components and technology conference (ECTC), pp 612–618

Orii Y, Toriyama K, Noma H, Oyama Y, Nishiwaki H, Ishida M, Nishio T, LaBianca NC, Feger C (2009) Ultrafine-pitch C2 flip chip interconnections with solder-capped Cu pillar bumps. In: 2009 59th electronic components and technology conference, pp 948–953

Moga KA, Bickford LR, Geil RD, Dunn SS, Pandya AA, Yapei W, Fain JH, Archuleta CF, O’Neill AT, DeSimone JM (2013) Rapidly–dissolvable microneedle patches via a highly scalable and reproducible soft lithography approach. Adv Mater 25(36):5060–5066

Kim Y-C, Park J-H, Prausnitz MR (2012) Microneedles for drug and vaccine delivery. Adv Drug Deliv Rev 64(14):1547–1568

Demko MT, Cheng JC, Pisano AP (2010) High-resolution direct patterning of gold nanoparticles by the ic molding process. Langmuir 26(22):16710–16714

Kim E, Xia Y, Whitesides GM (1995) Polymer microstructures formed by moulding in capillaries. Nature 376:581

Leng J, Lonetti B, Tabeling P, Joanicot M, Ajdari A (2006) Microevaporators for kinetic exploration of phase diagrams. Phys Rev Lett 96(8):84503

Moreau P, Dehmoune J, Salmon J-B, Leng J (2009) Microevaporators with accumulators for the screening of phase diagrams of aqueous solutions. Appl Phys Lett 95(3):33108

Randall GC, Doyle PS (2005) Permeation-driven flow in poly(dimethylsiloxane) ic devices. Proc Natl Acad Sci USA 102(31):10813. LP–10818

Duineveld PC, Lilja M, Johansson T, Inganäs O (2002) Diffusion of solvent in PDMS elastomer for micromolding in capillaries. Langmuir 18(24):9554–9559

Kretschmer CB, Wiebe R (1949) Liquid-vapor equilibrium of ethanol–toluene solutions. J Am Chem Soc 71(5):1793–1797

Mamedov AA, Aleskerov AM, Shikhaliev AY, Khalilov ShKh (1973) Variation of the viscosities and densities of carbon tetrachloride, ethanol, and their binary mixtures with temperature and concentrations, Viniti:1–8

Yi-Ming S, Jack C (2018) Sorption/desorption properties of ethanol, toluene, and xylene in poly(dimethylsiloxane) membranes. J Appl Polym Sci 51(10):1797–1804

Demko MT, Cheng JC, Pisano AP (2012) Rigid, vapor-permeable poly(4-methyl-2-pentyne) templates for high resolution patterning of nanoparticles and polymers. ACS Nano 6(8):6890– 6896

Terasaki N, Dorsey K, Makihata M, Pisano AP (2017) Micro printing using microfluidics for printed biodegradable devices in trillion sensing. ECS Trans 75(41):13–19

Demko MT (2012) High resolution additive patterning of nanoparticles and polymers enabled by vapor permeable polymer templates, UC Berkeley, ProQuest ID Demko_berkeley_0028E_12305, Merritt ID: ark:/13030/m5125xk2. Retrieved from https://escholarship.org/uc/item/37n411xf

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Makihata, M., Pisano, A.P. High-throughput microstructure printing technology using inflatable thin membrane with microchannel. Int J Adv Manuf Technol 103, 1709–1719 (2019). https://doi.org/10.1007/s00170-019-03672-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03672-8