Abstract

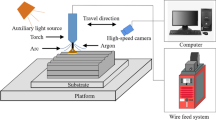

The wire-arc additive manufacturing (WAAM) process applies gas metal arc welding (GMAW) technology. The wire materials of aluminum alloy are melted to form metal droplet by the arc discharge and are accumulated layer-by-layer in this process. The arc voltage and arc acoustic emission (AE) signals were detected synchronously in the experiment. According to the signal feature of arc voltage and arc AE, the droplet transfer behaviors in various transfer modes were investigated based on the GMAW-WAAM process. Furthermore, significance of parameters was analyzed and computational models of droplet size and deposition rate were developed to evaluate the quality and efficiency of WAAM. The results showed that the identification of the characteristics of droplet transfer mode can be realized by means of arc signals analysis, which is an alternative method for the analysis of droplet transfer in the GMAW-WAAM process. The interaction of arc voltage and arc current (U × I) is the most important factor to influence the droplet transfer, and the cubic polynomial regression equation is a more ideal model to describe the relationship between the frequency of droplet transfer and arc power. The droplet radius decreases exponentially with the increase of frequency of droplet transfer, and the deposition rate increases with the increase of droplet transfer frequency by cubic polynomial rule.

Similar content being viewed by others

References

Zhang JK, Zhang X, Wang XY, Ding JL, Traoré Y, Paddea S, Williams S (2016) Crack path selection at the interface of wrought and wire + arc additive manufactured Ti–6Al–4V. Mater Des 104:365–375

Abe T, Sasahara H (2016) Dissimilar metal deposition with a stainless steel and nickel-based alloy using wire and arc-based additive manufacturing. Precis Eng 45:387–395

Kobryn PA, Semiatin SL (2001) The laser additive manufacture of Ti-6Al-4V. JOM 53:40–42

Furumoto T, Ueda T, Alkahari MR, Hosokawa A (2013) Investigation of laser consoli-dation process for metal powder by two-color pyrometer and high-speed videocamera. CIRP Ann Manuf Technol 62:223–226

Xiong J, Yin ZQ, Zhang WH (2016) Closed-loop control of variable layer width for thin-walled parts in wire and arc additive manufacturing. J Mater Process Technol 233:100–106

Bermingham MJ, Kent D, Zhan H, StJohn DH, Dargusch MS (2015) Controlling the microstructure and properties of wire arc additive manufactured Ti–6Al–4V with trace boron additions. Acta Mater 91:289–303

Yang DQ, He CJ, Zhang GJ (2016) Forming characteristics of thin-wall steel parts by double electrode GMAW based additive manufacturing. J Mater Process Technol 227:153–160

Ma Y, Cuiuri D, Shen C, Li HJ, Pan ZX (2015) Effect of interpass temperature on in-situ alloying and additive manufacturing of titanium aluminides using gas tungsten arc welding. Add Manuf 8:71–77

Wang JF, Sun QJ, Wang H, Liu JP, Feng JC (2016) Effect of location on microstructure and mechanical properties of additive layer manufactured Inconel 625 using gas tungsten arc welding. Mater Sci Eng A 676:395–405

Shen C, Pan ZX, Cuiuri D, Dong BS, Li HJ (2016) In-depth study of the mechanical properties for Fe3Al based iron aluminide fabricated using the wire-arc additive manufacturing process. Mater Sci Eng A 669:118–126

Ding DH, Pan ZX, Cuiuri D, Li HJ (2015) A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot Cim-Int Manuf 31:101–110

Ding DH, Pan ZX, Cuiuri D, Li HJ, Van Duin S, Larkin N (2016) Bead modelling and implementation of adaptive MAT path in wire and arc additive manufacturing. Robot Cim-Int Manuf 39:32–42

Ding J, Colegrove P, Martina F, Williams S, Wiktorowicz R, Palt MR (2015) Development of a laminar flow local shielding device for wire + arc additive manufacture. J Mater Proc Technol 226:99–105

Zhang Z, Chen S (2015) Data-driven feature selection for multisensory quality monitoring in arc welding. Robot Weld Int Auto 363:401–410

Anzehaee MM, Haeri M (2011) Estimation and control of droplet size and frequency in projected spray mode of a gas metal arc welding (GMAW) process. ISA Trans 50:409–418

Tipi ARD, Sani SKH, Pariz N (2015) Improving the dynamic metal transfer model of gas metal arc welding (GMAW) process. Int J Adv Manuf Technol 76:657–668

Scotti A, Ponomarev V, Lucas W (2014) Interchangeable metal transfer phenomenon in GMA welding: features, mechanisms, classification. J Mater Proc Technol 214:2488–2496

Sun Z, Lv YH, Xu BS, Liu YX, Lin JJ, Wang KB (2015) Investigation of droplet transfer behaviours in cold metal transfer (CMT) process on welding Ti-6Al-4V alloy. Int J Adv Manuf Technol 80:1–8

Choi JH, Lee JY, Yoo CD (2001) Simulation of dynamic behavior in a GMAW system. Weld J 80:239–246

Norrish J, Cuiuri D (2014) The controlled short circuit GMAW process: a tutorial. J Manuf Process 16:86–92

Acknowledgements

This work was supported by the Basic Science and Frontier Technology Research Project of the Chongqing Science and Technology Commission of China (Grant No. cstc2017jcyjBX0065 and No. cstc2015jcyjA60009) and the fund of the State Key Laboratory of Solidification Processing in NWPU (Grant No. SKLSP201717).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liang, Z., Jinglong, L., Yi, L. et al. Characteristics of metal droplet transfer in wire-arc additive manufacturing of aluminum alloy. Int J Adv Manuf Technol 99, 1521–1530 (2018). https://doi.org/10.1007/s00170-018-2604-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2604-7