Abstract

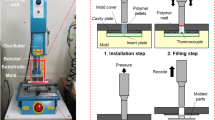

Ultrasound injection molding has emerged as an alternative production route for the manufacturing of micro-scale polymeric components, where it offers significant benefits over the conventional micro-injection molding process. In this work, the effects of ultrasound melting on the mechanical and morphological properties of micro-polypropylene parts were characterized. The ultrasound injection molding process was experimentally compared to the conventional micro-injection molding process using a novel mold, which allows mounting on both machines and visualization of the melt flow for both molding processes. Direct measurements of the flow front speed and temperature distributions were performed using both conventional and thermal high-speed imaging techniques. The manufacturing of micro-tensile specimens allowed the comparison of the mechanical properties of the parts obtained with the different processes. The results indicated that the ultrasound injection molding process could be an efficient alternative to the conventional process.

Similar content being viewed by others

References

Attia UM, Marson S, Alcock JR (2009) Micro-injection moulding of polymer microfluidic devices. Microfluid Nanofluid 7(1):1–28

Tseng SC, Chen YC, Kuo CL, Shew BY (2005) A study of integration of LIGA and M-EDM technology on the microinjection molding of ink-jet printers’ nozzle plates. Microsyst Technol 12(1–2):116–119

Angelov AK, Coulter JP (2008) The development and characterization of polymer microinjection molded gratings. Polym Eng Sci 48(11):2169–2177

Wallrabe, U., Dittrich, H., Friedsam, G., Hanemann, T., Mohr, J., Müller, K., . & Zißler, W. (2002). Micromolded easy-assembly multi fiber connector: RibCon®. Microsyst Technol, 8(2–3), 83–87

Yang C, Yin XH, Cheng GM (2013) Microinjection molding of microsystem components: new aspects in improving performance. J Micromech Microeng 23(9):093001

Whiteside BR, Martyn MT, Coates PD, Allan PS, Hornsby PR, Greenway G (2003) Micromoulding: process characteristics and product properties. Plast Rubber Compos 32(6):231–239

Hansen HN, Hocken RJ, Tosello G (2011) Replication of micro and nano surface geometries. CIRP Annals-Manufacturing Technology 60(2):695–714

Sorgato M, Masato D, Lucchetta G (2017) Effect of vacuum venting and mold wettability on the replication of micro-structured surfaces. Microsyst Technol 23(7):2543–2552

Sha B, Dimov S, Griffiths C, Packianather MS (2007) Micro-injection moulding: factors affecting the achievable aspect ratios. Int J Adv Manuf Technol 33(1–2):147–156

Masato D, Sorgato M, Lucchetta G (2016) Analysis of the influence of part thickness on the replication of micro-structured surfaces by injection molding. Mater Des 95:219–224

Lucchetta G, Sorgato M, Carmignato S, Savio E (2014) Investigating the technological limits of micro-injection molding in replicating high aspect ratio micro-structured surfaces. CIRP Annals-Manufacturing Technology 63(1):521–524

Masato D, Rathore J, Sorgato M, Carmignato S, Lucchetta G (2017) Analysis of the shrinkage of injection-molded fiber-reinforced thin-wall parts. Mater Des 132:496–504

Lucchetta G, Masato D, Sorgato M, Crema L, Savio E (2016) Effects of different mould coatings on polymer filling flow in thin-wall injection moulding. CIRP Annals-Manufacturing Technology 65(1):537–540

Giboz J, Copponnex T, Mélé P (2009) Microinjection molding of thermoplastic polymers: morphological comparison with conventional injection molding. J Micromech Microeng 19(2):025023

Michaeli W, Spennemann A, Gärtner R (2002) New plastification concepts for micro injection moulding. Microsyst Technol 8(1):55–57

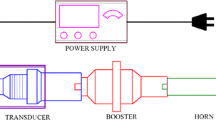

Michaeli W, Kamps T, Hopmann C (2011) Manufacturing of polymer micro parts by ultrasonic plasticization and direct injection. Microsyst Technol 17(2):243–249

Wu W, Peng H, Jia Y, Jiang B (2017) Characteristics and mechanisms of polymer interfacial friction heating in ultrasonic plasticization for micro injection molding. Microsyst Technol 23(5):1385–1392

Jiang B, Peng H, Wu W, Jia Y, Zhang Y (2016) Numerical simulation and experimental investigation of the viscoelastic heating mechanism in ultrasonic plasticizing of amorphous polymers for micro injection molding. Polymers 8(5):199

Chen G, Guo S, Li H (2002) Ultrasonic improvement of rheological behavior of polystyrene. J Appl Polym Sci 84(13):2451–2460

Chen J, Chen Y, Li H, Lai SY, Jow J (2010) Physical and chemical effects of ultrasound vibration on polymer melt in extrusion. Ultrason Sonochem 17(1):66–71

Ávila-Orta C, Espinoza-González C, Martínez-Colunga G, Bueno-Baqués D, Maffezzoli A, Lionetto F (2013) An overview of progress and current challenges in ultrasonic treatment of polymer melts. Adv Polym Technol 32(S1):E582–E602

Sacristan M, Planta X, Morell M, Puiggali J (2014) Effects of ultrasonic vibration on the micro-molding processing of polylactide. Ultrason Sonochem 21(1):376–386

Grabalosa J, Ferrer I, Elías-Zúñiga A, Ciurana J (2016) Influence of processing conditions on manufacturing polyamide parts by ultrasonic molding. Mater Des 98:20–30

Michaeli W, Starke C (2005) Ultrasonic investigations of the thermoplastics injection moulding process. Polym Test 24(2):205–209

Negre Gubau P, Grabalosa Saubí J, Ferrer Real I, Ciurana QD (2015) Study of the ultrasonic molding process parameters for manufacturing polypropylene parts. Proc Eng 32:7–14

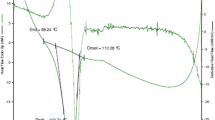

Ma Z, Balzano L, Portale G, Peters GW (2014) Flow induced crystallization in isotactic polypropylene during and after flow. Polymer 55(23):6140–6151

Babenko M, Sweeney J, Petkov P, Lacan F, Bigot S, Whiteside B (2018) Evaluation of heat transfer at the cavity-polymer interface in microinjection moulding based on experimental and simulation study. Appl Therm Eng 130:865–876

Fischer, C., & Drummer, D. (2016). Crystallization and mechanical properties of polypropylene under processing-relevant cooling conditions with respect to isothermal holding time. Int J Polym Sci 2016

Schrauwen BA, Janssen RP, Govaert LE, Meijer HE (2004) Intrinsic deformation behavior of semicrystalline polymers. Macromolecules 37(16):6069–6078

Gao S, Qiu Z, Ma Z, Yang Y (2017) Flow properties of polymer melt in longitudinal ultrasonic-assisted microinjection molding. Polym Eng Sci 57(8):797–805

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Masato, D., Babenko, M., Shriky, B. et al. Comparison of crystallization characteristics and mechanical properties of polypropylene processed by ultrasound and conventional micro-injection molding. Int J Adv Manuf Technol 99, 113–125 (2018). https://doi.org/10.1007/s00170-018-2493-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2493-9