Abstract

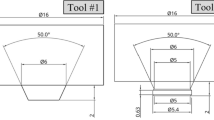

The fabrication friction stir welded lap joints with Al 7075-T6 sheets is examined with a wide range of tool pin geometries and dimensions while comparing microstructures, bonded area geometry, hardness, and fracture load during overlap shear testing. The tool pin geometry and features significantly affected the hook geometry and thus weld strength and failure mode. A hook feature is prone to forming when a larger diameter or helical threaded tool pins are used and is shown to deteriorate overlap shear fracture load by reducing the bonded ligament in the upper sheet. This hook feature can be controlled by removing the helical threads on the tool pin and replacing these with concentric grooves. The overlap shear fracture load is controlled by a combination of the sheet thickness, the width of the bonded area, and extent of the hook feature. These factors are captured in a model which was shown to provide good predictions of the fracture load and can be used to select tool pin sizes for varying overlapping sheet thicknesses.

Similar content being viewed by others

References

Shanavas S, Dhas JER, Murugan N (2018) Weldability of marine grade AA 5052 aluminum alloy by underwater friction stir welding. Int J Adv Manuf Technol 95(1–12):4535–4546

Mironov S, Onuma T, Sato Y, Yoneyama S, Kokawa H (2017) Tensile behavior of friction-stir welded AZ31 magnesium alloy. Mater Sci Eng A 679:272–281

Heidarzadeh A, Jabbari M, Esmaily M (2015) Prediction of grain size and mechanical properties in friction stir welded pure copper joints using a thermal model. Int J Adv Manuf Technol 77(9–12):1819–1829

Brassington W, Colegrove PA (2017) Alternative friction stir welding technology for titanium–6Al–4V propellant tanks within the space industry. Sci Technol Weld Join 22(4):300–318

Manvatkar V, De A, Svensson L-E, DebRoy T (2015) Cooling rates and peak temperatures during friction stir welding of a high-carbon steel. Scr Mater 94:36–39

R. Kumar, R. Singh, I. Ahuja, R. Penna, L. Feo (2017) Weldability of thermoplastic materials for friction stir welding—a state of art review and future applications, Compos Part B

Shen Z, Chen Y, Haghshenas M, Gerlich A (2015) Role of welding parameters on interfacial bonding in dissimilar steel/aluminum friction stir welds. Engineering Science and Technology, an International Journal 18(2):270–277

Shen Z, Chen Y, Haghshenas M, Nguyen T, Galloway J, Gerlich A (2015) Interfacial microstructure and properties of copper clad steel produced using friction stir welding versus gas metal arc welding. Mater Charact 104:1–9

R.S. Mishra, P.S. De, N. Kumar, Friction stir welding and processing: science and engineering, Springer2014

Babu S, Ram GJ, Venkitakrishnan P, Reddy GM, Rao KP (2012) Microstructure and mechanical properties of friction stir lap welded aluminum alloy AA2014. J Mater Sci Technol 28(5):414–426

Salari E, Jahazi M, Khodabandeh A, Ghasemi-Nanesa H (2014) Influence of tool geometry and rotational speed on mechanical properties and defect formation in friction stir lap welded 5456 aluminum alloy sheets. Mater Des 58:381–389

Yue Y, Li Z, Ji S, Huang Y, Zhou Z (2016) Effect of reverse-threaded pin on mechanical properties of friction stir lap welded alclad 2024 aluminum alloy. J Mater Sci Technol 32(7):671–675

Liu H, Zhao Y, Hu Y, Chen S, Lin Z (2015) Microstructural characteristics and mechanical properties of friction stir lap welding joint of alclad 7B04-T74 aluminum alloy. Int J Adv Manuf Technol 78(9–12):1415–1425

Yang Q, Li X, Chen K, Shi Y (2011) Effect of tool geometry and process condition on static strength of a magnesium friction stir lap linear weld. Mater Sci Eng A 528(6):2463–2478

Bisadi H, Tour M, Tavakoli A (2011) The influence of process parameters on microstructure and mechanical properties of friction stir welded Al 5083 alloy lap joint. American journal of Materials science 1(2):93–97

Song Y, Yang X, Cui L, Hou X, Shen Z, Xu Y (2014) Defect features and mechanical properties of friction stir lap welded dissimilar AA2024–AA7075 aluminum alloy sheets. Mater Des 55:9–18

Chen H, Fu L, Liang P, Liu F (2017) Defect features, texture and mechanical properties of friction stir welded lap joints of 2A97 Al-Li alloy thin sheets. Mater Charact 125:160–173

Imam M, Racherla V, Biswas K (2015) Effect of backing plate material in friction stir butt and lap welding of 6063-T4 aluminium alloy. Int J Adv Manuf Technol 77(9–12):2181–2195

Wang M, Zhang H, Zhang J, Zhang X, Yang L (2014) Effect of pin length on hook size and joint properties in friction stir lap welding of 7B04 aluminum alloy. J Mater Eng Perform 23(5):1881–1886

Fadaeifard F, Gharavi F, Matori KA, Daud AR, Ariffin M, Awang M (2014) Investigation of microstructure and mechanical properties of friction stir lap welded AA6061-T6 in various welding speeds. J Appl Sci 14(3):221–228

Zhou Z, Yue Y, Ji S, Li Z, Zhang L (2017) Effect of rotating speed on joint morphology and lap shear properties of stationary shoulder friction stir lap welded 6061-T6 aluminum alloy. Int J Adv Manuf Technol 88(5–8):2135–2141

Ji S, Li Z, Zhou Z, Wu B (2017) Effect of thread and rotating speed on material flow behavior and mechanical properties of friction stir lap welding joints. J Mater Eng Perform 26(10):5085–5096

Xu Z, Li Z, Lv Z, Zhang L (2017) Effect of welding speed on joint features and lap shear properties of stationary shoulder FSLWed Alclad 2024 Al alloy. J Mater Eng Perform 26(3):1358–1364

Rajendran C, Srinivasan K, Balasubramanian V, Balaji H, Selvaraj P (2017) Identifying combination of friction stir welding parameters to maximize strength of lap joints of AA2014-T6 aluminium alloy. Aust J Mech Eng:1–12

Yue Y, Zhou Z, Ji S, Zhang L, Li Z (2017) Improving joint features and tensile shear properties of friction stir lap welded joint by an optimized bottom-half-threaded pin tool. Int J Adv Manuf Technol 90(9–12):2597–2603

Balakrishnan M, Leitão C, Arruti E, Aldanondo E, Rodrigues D (2018) Influence of pin imperfections on the tensile and fatigue behaviour of AA 7075-T6 friction stir lap welds. Int J Adv Manuf Technol:1–11

Zou S, Ma S, Liu C, Chen C, Ma L, Lu J, Guo J (2016) Multi-track friction stir lap welding of 2024 aluminum alloy: processing, microstructure and mechanical properties. Metals 7(1):1

Gao S, Wu C, Padhy G (2018) Process and joint quality of ultrasonic vibration enhanced friction stir lap welding. Sci Technol Weld Join:1–11

Liu H, Hu Y, Peng Y, Dou C, Wang Z (2016) The effect of interface defect on mechanical properties and its formation mechanism in friction stir lap welded joints of aluminum alloys. J Mater Process Technol 238:244–254

Buffa G, Campanile G, Fratini L, Prisco A (2009) Friction stir welding of lap joints: influence of process parameters on the metallurgical and mechanical properties. Mater Sci Eng A 519(1–2):19–26

Mitlin D, Radmilovic V, Pan T, Chen J, Feng Z, Santella M (2006) Structure–properties relations in spot friction welded (also known as friction stir spot welded) 6111 aluminum. Mater Sci Eng A 441(1–2):79–96

Shen Z, Yang X, Zhang Z, Cui L, Li T (2013) Microstructure and failure mechanisms of refill friction stir spot welded 7075-T6 aluminum alloy joints. Mater Des 44:476–486

Shen Z, Chen Y, Hou J, Yang X, Gerlich A (2015) Influence of processing parameters on microstructure and mechanical performance of refill friction stir spot welded 7075-T6 aluminium alloy. Sci Technol Weld Join 20(1):48–57

Shen Z, Ding Y, Gopkalo O, Diak B, Gerlich A (2018) Effects of tool design on the microstructure and mechanical properties of refill friction stir spot welding of dissimilar Al alloys. J Mater Process Technol 252:751–759

R.H. Wagoner, J.-L. Chenot, Metal forming analysis, Cambridge University Press, 2001

Tabor D (1951) The hardness of metals. Clarendon, Oxford

D.R.H. Jones, M.F. Ashby, Engineering materials 2: an introduction to microstructures, processing and design, Elsevier 2005

Funding

The authors acknowledge the financial support provided to Huihui Zhao by the China Scholarship Council (CSC) during the present investigation. Further financial and material support from the Natural Sciences and Engineering Research Council of Canada is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, H., Shen, Z., Booth, M. et al. Calculation of welding tool pin width for friction stir welding of thin overlapping sheets. Int J Adv Manuf Technol 98, 1721–1731 (2018). https://doi.org/10.1007/s00170-018-2350-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2350-x