Abstract

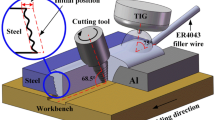

Magnetic pulse welding (MPW) has attracted widespread attention due to its advantages on joining dissimilar metals. This paper mainly focused on the effect of surface treatment on the weldability and mechanical properties of Al-Fe joints. Two kinds of surface grinding directions, including parallel to welding direction (P2W) and vertical to welding direction (V2W), were designed to prepare MPW joints. Mechanical properties and interface microstructures were systematically analyzed to establish the corresponding relationship between the two. Results showed V2W welded joints presented a wavy-shape interface and had better mechanical properties. The P2W specimens only showed a straight interface, and the element diffusion in the zone of the wave interface was better than that in the zone of the straight interface. The discharge energies affected mechanical properties by changing the interfacial morphology. In addition, the formed jets could be trapped and led to the formation of interfacial waves when the scratch direction did not coincide with the welding direction, contributing to the formation mechanism of wave interface.

Similar content being viewed by others

References

Kapil A, Sharma A (2015) Magnetic pulse welding: an efficient and environmentally friendly multi-material joining technique. J Clean Prod 100:35–58

Broeckhove J, Willemsens L, Faes K, Waele WD (2011) Magnetic pulse welding. Sustain Constr Des 1:21–28

Yu H, Tong Y (2017) Magnetic pulse welding of aluminum to steel using uniform pressure electromagnetic actuator. Int J Adv Manuf Technol 91:2257–2265

Marya M, Marya S (2014) Interfacial microstructures and temperatures in aluminium–copper electromagnetic pulse welds. Sci Technol Weld Join 9:541–547

Kore SD, Imbert J, Worswick MJ, Zhou Y (2009) Electromagnetic impact welding of Mg to Al sheets. Sci Technol Weld Join 14:549–553

Yu H, Xu Z, Fan Z, Zhao Z, Li C (2013) Mechanical property and microstructure of aluminum alloy-steel tubes joint by magnetic pulse welding. Mater Sci Eng A 561:259–265

Kang BY (2015) Review of magnetic pulse welding. J Weld Join 33:7–13

Verstraete J, Waele WD, Faes K (2011) Magnetic pulse welding: lessons to be learned from explosive welding. Sustain Constr Des 2:458–464

Bai QL, Zhang LJ, Xie MX, Yang HX, Zhang JX (2017) An investigation into the inhomogeneity of the microstructure and mechanical properties of explosive welded H62-brass/Q235B-steel clad plates. Int J Adv Manuf Technol 90:1351–1363

Zhang Y, Babu SS, Prothe C, Blakely M, Kwasegroch J, Laha M, Daehn GS (2011) Application of high velocity impact welding at varied different length scales. J Mater Process Technol 211:944–952

Crossland B, Williams JD (1970) Explosive welding. Int Mater Rev 15:79–100

Watanabe M, Kumai S (2009) High-speed deformation and collision behavior of pure aluminum plates in magnetic pulse welding. Mater Trans 50:2035–2042

Xu Z, Cui J, Yu H, Li C (2013) Research on the impact velocity of magnetic impulse welding of pipe fitting. Mater Des 49:736–745

Garg A, Panda B, Shankhwar K (2016) Investigation of the joint length of weldment of environmental-friendly magnetic pulse welding process. Int J Adv Manuf Technol 87:2415–2426

Groche P, Wagner MFX, Pabst C, Sharafiev S (2014) Development of a novel test rig to investigate the fundamentals of impact welding. J Mater Process Technol 214:2009–2017

Reid SR (1974) A discussion of the mechanism of interface wave generation in explosive welding. Int J Mech Sci 16:399–413

Leena K, Athira KK, Bhuvaneswari S, Suraj S, Rao VL (2016) Effect of surface pre-treatment on surface characteristics and adhesive bond strength of aluminium alloy. Int J Adhes Adhes 70:265–270

Borsellino C, Bella GD, Ruisi VF (2009) Adhesive joining of aluminium AA6082: the effects of resin and surface treatment. Int J Adhes Adhes 29:36–44

Dawood HI, Mohammed KS, Rahmat A, Uday MB (2015) The influence of the surface roughness on the microstructures and mechanical properties of 6061 aluminum alloy using friction stir welding. Surf Coat Technol 270:272–283

Wu X, Shang J (2014) An investigation of magnetic pulse welding of Al/Cu and interface characterization. J Manuf Sci Eng 136:051002

Berlin A, Nguyen TC, Worswick MJ, Zhou Y (2013) Metallurgical analysis of magnetic pulse welds of AZ31 magnesium alloy. Sci Technol Weld Join 16:728–734

Watanabe M, Kumai S (2009) Interfacial morphology of magnetic pulse welded aluminum/aluminum and copper/copper lap joints. Mater Trans 50:286–292

Cui J, Sun G, Li G, Xu Z, Chu PK (2014) Specific wave interface and its formation during magnetic pulse welding. Appl Phys Lett 105:2588

Watanabe M, Kumai S, Aizawa T (2006) Interfacial microstructure of magnetic pressure seam welded Al-Fe, Al, Ni and Al-Cu lap joints. Mater Sci Forum 519:1145–1150

Kakizaki S, Watanabe M, Kumai S (2011) Simulation and experimental analysis of metal jet emission and weld interface morphology in impact welding. Mater Trans 52:1003–1008

Acknowledgments

The authors would like to take this opportunity to express their sincere appreciation.

Funding

This paper was financially supported by the National Natural Science Foundation of China (No. 51405149), the State Key Program of National Natural Science Foundation of China (No. 61232014), and Natural Science Foundation of Hunan Province, China (No. 2015JJ3038).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, J., Sun, T., Geng, H. et al. Effect of surface treatment on the mechanical properties and microstructures of Al-Fe single-lap joint by magnetic pulse welding. Int J Adv Manuf Technol 98, 1081–1092 (2018). https://doi.org/10.1007/s00170-018-2262-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2262-9