Abstract

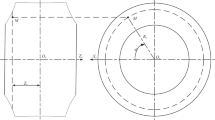

To improve the machining quality and volumetric efficiency of triple-screw pumps, the screws are ground and processed using a computer numerical control (CNC) grinder. In this paper, we propose a new method to determine the arc repaired width of a driven screw in order to solve the problem of sharp transverse profile corners that cannot be ground due to either no repair or repairs with an inappropriate ratio of screw pitch diameter. Herein, parametric equations for the driven screw transverse profile repair are defined based on a grinding model for triple-screw pump screws. The relationship between the rim radius of the diamond wheel and the repaired width of the driven screw is established. Finally, a law to determine the minimum repaired width of the driven screw is defined and the theoretical basis for triple-screw pump screw CNC grinding is provided.

Similar content being viewed by others

References

Wei J, Sun Q, Sun X, Sun W (2013) A study on rotor profile design for a novel twin-screw kneader. Int J Precis Eng Manuf 14(3):451–459

Muhammed AR, Childs DW (2013) Rotordynamics of a two-phase flow twin screw pump. J Eng Gas Turbines Power 135(6):062502

Stosic N, Smith IK, Kovacevic A, Mujic E (2011) Geometry of screw compressor rotors and their tools. Journal of Zhejiang University-SCIENCE A 12(4):310–326

Wei J, Zhang G (2010) A precision grinding method for screw rotors using CBN grinding wheel. Int J Adv Manuf Technol 48(5–8):495–503

Burenin VV, Gaevik DT (1976) New designs of screw pumps survey foreign patents. Chem Pet Eng 12(8):751–753

Okorokov V, Verizhnikov P, Ryazantsev V (1986) New triple-screw pumps for pumping high-viscosity liquids. Chem Pet Eng 22(8):361–362

Xu J, Feng Q, Wu W (2011) Geometrical design and investigation of a new profile of the three screw pump. J Mech Des 133(9):094501

Tang Q, Zhang Y (2014) Screw optimization for performance enhancement of a twin-screw pump. Part E: J Process Mechanical Engineering 228(1):73–84

Ryazantsev VM, trel’nik TAS (1989) Triple-screw pumps with high specific load on the housing. Chem Pet Eng 25(9):485–486

Zhao Y, Zhao S, Wei W, Hou H (2016) Precision grinding of screw rotors using CNC method. Int J Adv Manuf Technol, 2017, 89(9–12): 2967–2979

Wei W, Zhang G (2016) Tool path modeling and error sensitivity analysis of crankshaft pin CNC grinding. Int J Adv Manuf Technol 86(9–12):2485–2502

Xueming H, Chenglong P, Meiping W, Xiaogang J (2015) A twin-screw rotor profile design method based on computational fluid dynamics. Advanced Multimedia and Ubiquitous Engineering 352:337–342

Papes I, Degroote J, Vierendeels J (2015) New insights in twin screw expander performance for small scale ORC systems from 3D CFD analysis. Applied Thermal Engineering

Mimmi G, Pennacchi P (1997) Determination of tool profile for the milling of three-screw pump rotor. Meccanica 32(4):363–377

Lyashkov A, Panchuk K (2015) Computer modeling of a pump screw and disc tool cross shaping process. Procedia Engineering 113:174–180

Acknowledgements

This study was supported by the contribution of the National Natural Science Foundation of China (Grant No. 51405378) and additional support from the Major National Science and Technology Project of China (Grant No. 2009ZX04005-031) and Foundation of Shaanxi Province Educational Committee (Grant No. 16JK1166).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, Y., Zhao, S., Hou, H. et al. Determining the repair width and CNC grinding of screws of triple-screw pump. Int J Adv Manuf Technol 97, 389–400 (2018). https://doi.org/10.1007/s00170-018-1943-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1943-8