Abstract

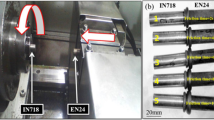

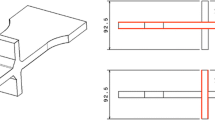

Linear friction welding is a solid-state process that comprises rapid heating and cooling of the welded parts. Residual stresses (RS) as in every other welding process cannot be avoided. The presence of RS compromises the in-service performance and reliability. They influence stress corrosion cracking, fatigue strength, and the crack growth rate. Knowing the magnitude and nature of such stresses is critical for improving the quality of welded joints. Therefore, four different manufacturing stages of linear friction welded chain links were analyzed in the present study: “as forged” (F), “as welded” (A), “as welded” without flash (N), and post weld heat treated (P). The residual stress field was measured using the hole drilling (HD) method. The results of the hole drilling method showed to be independent of the measured position and symmetry with respect to the weld was observed in all evaluated regions. Close to the weld center line (WCL), the compressive stresses present in the “as forged” condition switched to tensile as a result of the welding process. However, in further regions, stresses remained almost unchanged for either A and N. The PWHT uniformizes the residual stress field along the whole weld region.

Similar content being viewed by others

References

Funderburk S (1986) Postweld heat treatments, pergamon press Ltd., Encycl. Mater …, vol. XV, no. 2

McAndrew AR, Colegrove PA, Flipo BCD, Bühr C (2016) 3D modelling of Ti–6Al–4V linear friction welds. Sci Technol Weld Join., vol. XXII. (December) p 1–9

Bhamji I, Preuss M, Threadgill PL, Moat RJ, Addison AC, Peel MJ (2010) Linear friction welding of AISI 316L stainless steel. Mater Sci Eng A 528(2):680–690

Smith M, Levesque J-B, Bichler L, Sediako D, Gholipour J, Wanjara P (2017) Residual stress analysis in linear friction welded in-service Inconel 718 superalloy via neutron diffraction and contour method approaches. Mater Sci Eng A 691(February):168–179

Vairis A (2012) Mathematical modelling of the linear friction welding process. J Eng Sci Technol Rev 5(3):25–31

Li WY, Ma TJ, Yang SQ, Xu QZ, Zhang Y, Li JL, Liao HL (2008) Effect of friction time on flash shape and axial shortening of linear friction welded 45 steel. Mater Lett 62(2):293–296

Bhamji I, Preuss M, Threadgill PL, Addison AC (2011) Solid state joining of metals by linear friction welding: a literature review. Mater Sci Technol 27(1):2–12

Schajer GS (2010) Advances in hole-drilling residual stress measurements. Exp Mech 50(2):159–168

Schajer GS (2009) Hole-drilling residual stress measurements at 75: origins, advances, opportunities, Exp Mech, vol. L

Rendler NJ, Vigness I (1966) Hole-drilling strain-gage method of measuring residual stresses. Exp Mech 6(12):577–586

Rossini NS, Dassisti M, Benyounis KY, Olabi AG (2012) Methods of measuring residual stresses in components. Mater Des 35:572–588

Barile C, Casavola C, Pappalettera G, Pappalettere C (2014) Remarks on residual stress measurement by hole-drilling and electronic speckle pattern interferometry. ScientificWorldJournal 2014:1–7

Lohe D, Vohringer O (2002) Handbook of residual stress and deformation of steel, vol. I

V. P. Group (2010) Measurement of residual stresses by the hole-drilling* strain gage method, Tech Note TN-503 11053:19–33

Stefanescu D, Truman CE, Smith DJ, Whitehead PS (2006) Improvements in residual stress measurement by the incremental centre hole drilling technique. Exp Mech 46(4):417–427

Effertz PS, Fuchs F, Enzinger N (2017) Modelling the flash formation of linear friction welded 30CrNiMo8 high strength steel chains. Int J Adv Manuf Technol 92:2479–2486

Loffelmann J (2012) Systematische Untersuchung der Schweissparameter beim linearen Reibschweissen.pdf, 2nd IIW European-South American School of Welding and Correlated Processes

Nobre JP, Kornmeier M, Dias AM, Scholtes B. Use of the hole-drilling method for measuring residual stresses in highly stressed shot-peened surfaces, vol. XL, p. 289–297

Buchanan DJ, John R (2014) A residual stress redistribution in shot peened samples subject to mechanical loading. Mater Sci Eng A 615:70–78

Xie P, Zhao H, Liu Y, Xie P, Zhao H, Liu Y (2017) Measuring residual stresses in linear friction welded joints composed by dissimilar titanium measuring residual stresses in linear friction welded joints composed by dissimilar titanium, Science and technology of welding and joining vol. XXI, no.5

Turner R, Ward RM, March R, Reed RC (2012) The magnitude and origin of residual stress in Ti-6Al-4V linear friction welds: an investigation by validated numerical modeling. Metall Mater Trans B Process Metall Mater Process Sci 43(1):186–197

Frankel P, Preuss M, Steuwer A, Withers PJ, Bray S (2009) Comparison of residual stresses in Ti-6Al-4V and Ti-6Al-2Sn-4Zr-2Mo linear friction welds. Mater Sci Technol 25(5):640–650

Acknowledgements

The authors gratefully acknowledge the financial support of this work by the project JOIN. The K-Project Network of Excellence for Joining Technologies JOIN is fostered in the frame of COMET—Competence Centers for Excellent Technologies by BMVIT, BMWFJ, FFG, Land Oberöstereich, Land Steiermark, SFG, and ZIT. The program COMET is handled by FFG.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nunes, D.G., Effertz, P.S., Quintino, L. et al. Residual stresses in 18CrNiMo7-6 linear friction welded high strength steel chains. Int J Adv Manuf Technol 96, 3703–3710 (2018). https://doi.org/10.1007/s00170-018-1850-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1850-z