Abstract

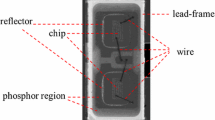

A crucial factor for ensuring the reliability of chip packages is the measurement and control of warpage. The warpage of chip packages, printed wiring boards (PWBs), and PWB assemblies (PWBAs) are typically measured by moiré techniques (i.e., shadow moiré, laser fringe projection, and digital fringe projection), which have noncontact, full-field, and high-resolution capabilities. The application of moiré techniques typically involves spraying a mist of reflective paint on the surface of a sample to ensure the uniformity of surface reflectance and to obtain better fringe image contrast and better sinusoidal waveforms in the fringe patterns for the measurement process. However, since painted samples may no longer be re-used, the process of spray painting is not suited for inline inspection; a new technique for measuring warpage without painting is required. In this research, a dynamic digital fringe projection (DDFP) technique for measuring the warpage of unpainted plastic ball grid array (PBGA) packages and boards was developed. The DDFP technique dynamically determines proper fringe intensity distributions for PBGA packages and PWBs and uses them to produce a better fringe image contrast and better sinusoidal waveforms without painting. Experimental results showed that the DDFP technique successfully measures the warpage of PBGA packages and PWBs in unpainted PWBAs accurately.

Similar content being viewed by others

References

Tummala R, Rymaszewski EJ, Klopfenstein AG (2001) Microelectronics packaging fundamentals. McGraw-Hill, New York

Tan W (2008) Development of convective reflow-projection moire warpage measurement system and prediction of solder bump reliability on board assemblies affected by warpage, Mech Eng. Georgia Institute of Technology, Atlanta, GA. http://hdl.handle.net/1853/22600

Ding H, Powell RE, Hanna CR, Ume IC (2002) Warpage measurement comparison using shadow Moire and projection Moire methods. IEEE Trans Comp Packag Technol 25:714–721

Kang S, Gong J, Ume IC (2011) Determination of Optimum Values of Control Parameters to Reduce Laser Speckle Noise for Projection Moiré System, ASME ASME International Mechanical Engineering Congress and Exposition 1:743–749. https://doi.org/10.1115/IMECE2011-62766

Gorthi SS, Rastogi P (2010) Fringe projection techniques: whither we are? Opt Lasers Eng 48:133–140

Chang C-S, Shao C-A, Wu E (2004) Micro-scaled surface profile measurement on packages by digital projection moiré. ASME Electron Photon Packag 4:161–166

Yen H-N, Tsai D-M, Yang J-Y (2006) Full-field 3-D measurement of solder pastes using LCD-based phase shifting techniques. IEEE Trans Electron Packag Manuf 29:50–57

Yen H-N, Tsai D-M, Feng S-K (2008) Full-field 3-D flip-chip solder bumps measurement using DLP-based phase shifting technique. IEEE Trans Adv Packag 31:830–840

Joo J-W, Kim H-J (2008) Nano-level high sensitivity measurement using microscopic Moiré interferometry. Transactions of the Korean Society of Mechanical Engineers—A 32:186–193

Pan J, Zwemer DA, Petriccione G, and Curry R (2006) Thermally-induced warpage measurement on small packages by a microscopic fringe projection system, Thermal and Thermomechanical Proceedings 10th Intersociety Conference on Phenomena in Electronics Systems, San Diego, CA, pp. 953–960. https://doi.org/10.1109/ITHERM.2006.1645449

Ri S, Muramatsu T, Saka M, Tanaka H (2012) Fast and accurate shape measurement system utilizing the fringe projection method with a ferroelectric liquid-crystal-on-silicon microdisplay. Opt Eng 51:081506–081501

Hertl M, Weidmann D (2011) Innovative assessment of thermomechanical stress effects in electronics components and assemblies. Electron Devic Fail Anal 13:4–11

Liu XFHZW, Xie HM, Lou XH, Du H (2011) The artificial periodic lattice phase analysis method applied to deformation evaluation of TiNi shape memory alloy in micro scale. Meas Sci Technol 22:125702

Liu Z, Huang X, Xie H (2013) A novel orthogonal transmission-virtual grating method and its applications in measuring micro 3-D shape of deformed liquid surface. Opt Lasers Eng 51:167–171

Kang S, Ume IC (2014) Comparison of warpage measurement capabilities and results obtained by using laser and digital fringe projection methods. J Electron Packag 136:031007–031007

Zhang S (2006) High-resolution, real-time 3-D shape measurement, Ph.D. Dissertation, Dept. of Mechanical Engineering, Stony Brook University, Stony Brook, NY. http://eds.a.ebscohost.com/eds/detail/detail?vid=0&sid=a099198c-b526-4492-a6c0-f8cbb2f805ad%40sessionmgr4008amp;bdata=JnNpdGU9ZWRzLWxpdmUmc2NvcGU9c2l0ZQ%3d%3d

Cloud GL (1995) Optical Methods of Engineering Analysis, Cambridge University Press. https://doi.org/10.1017/CBO9780511575013

Ghiglia DC and Pritt MD (1998) Two-dimensional phase unwrapping: theory, algorithms, and software. Wiley. https://books.google.com/books/about/Two_dimensional_phase_unwrapping.html?id=pQtTAAAAMAAJ

Ding H (2003) Prediction and Validation of Thermomechanical Reliability in Electronic Packaging, Ph.D. Dissertation, School of Mechanical Engineering, Georgia Institute of Technology, Atlanta, GA. http://hdl.handle.net/1853/17565

Takeda M, Ina H, Kobayashi S (1982) Fourier-transform method of fringe-pattern analysis for computer-based topography and interferometry. J Opt Soc Am 72:156–160

Proll K-P, Nivet J-M, Körner K, Tiziani HJ (2003) Microscopic three-dimensional topometry with ferroelectric liquid-crystal-on-silicon displays. Appl Opt 42:1773–1778

Falcao G, Hurtos N, Massich J (2008) Plane-based calibration of a projectorcamera system. VIBOT Master 9(1):1-12. Available at https://www.researchgate.net/profile/Joan_Massich/publication/265230871_Planebased_calibration_of_a_projector-camera_system/links/54db26570cf261ce15cf4cd1/Plane-basedcalibration-of-a-projector-camera-system.pdf

Sukthankar R, Stockton RG, and Mullin MD (2001) Smarter presentations: exploiting homography in camera-projector systems, in Proceedings of IEEE International Conference on Computer Vision 482:247–253

Lohry WF, Xu Y, and Zhang S (2009) Optimal checkerboard selection for structured light system calibration, Optical Inspection and Metrology for Non-Optics Industries, vol. 7432. San Diego, CA, p 743202. https://doi.org/10.1117/12.823829

Kang S and Ume IC (2014) Automatic segmentation method for segmenting PBGA package and PWB regions during warpage measurement of unpainted PWB assembly, in International Symposium on Microelectronics, San Diego pp. 580–584

Solomon C and Breckon T (2011) Fundamentals of Digital Image Processing: A Practical Approach with Examples in Matlab. Wiley. https://doi.org/10.1002/9780470689776

Canny J (1986) A computational approach to edge detection. IEEE Trans Pattern Anal Mach Intell 8:679–698

Adams R, Bischof L (1994) Seeded region growing. IEEE Trans Pattern Anal Mach Intell 16:641–647

Zhucheng L (2010) Accurate calibration methods for small-depth objects in digital fringe projection, Ph.D. Dissertation, Dept. of Mechanical and Aerospace Engineering, Seoul National University, Seoul, South Korea. http://www.riss.kr/search/detail/DetailView.do?p_mat_type=be54d9b8bc7cdb09&control_no=3867b4d4d74c5425ffe0bdc3ef48d419

Harding K (2012) Handbook of optical dimensional metrology. CRC Press. https://www.crcpress.com/Handbook-of-Optical-Dimensional-Metrology/Harding/p/book/9781439854815

Pham H (2006) Springer handbook of engineering statistics. Springer. http://www.springer.com/us/book/9781852338060

Badiru AB, Agustiady T (2012) Statistical techniques for project control. CRC Press. https://www.crcpress.com/Statistical-Techniques-for-Project-Control/Badiru-Agustiady/p/book/9781420083170

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kang, S., Ume, I.C. Dynamic digital fringe projection technique for measuring the warpage of unpainted PBGA packages and boards. Int J Adv Manuf Technol 96, 3235–3249 (2018). https://doi.org/10.1007/s00170-018-1819-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1819-y