Abstract

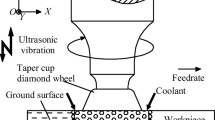

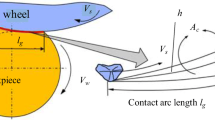

Silicon carbide (SiC) ceramics play a key role in various engineering applications due to their desirable properties, however, they are typical hard-brittle materials and famous for their poor machinability. Ultrasonic-assisted grinding, a processing method hybridizing the conventional grinding and ultrasonic vibration (UV) machining, is employed as the one applicable machining method for hard-brittle materials. This study focuses on internal grinding of SiC ceramics with the assistance of the UV, and its ductile-brittle transition behavior in the grinding process were investigated experimentally. Following the processing principal of internal grinding and UV machining (i.e., UV-assisted internal grinding, UVAIG), the UVAIG experiment rig were constructed. Conventional internal grinding (CIG) tests, i.e., internal grinding without UV, were also performed on the constructed rig for comparison. In addition, the grinding force and the grinding chips variation behavior with the UV amplitude were also investigated to explore the ductile-brittle transition mechanism in UVAIG. The experiment results evidence that (1) ductile mode grinding is easily achieved in UVAIG, and the critical depth of the cut is deeper in UVAIG than that in CIG, i.e., 0.072 μm in CIG and 0.093 μm in UVAIG; (2) increasing of the critical depth of cut in UVAIG is likely owing to the lower grinding force in UVAIG than that in CIG; and (3) the ultrasonic vibration acted on the axis of the grinding wheel helps in the removal of material on the work-surface, but decreases the grinding energy in the ductile-brittle transition.

Similar content being viewed by others

References

Cao J, Wu Y, Lu D, Fujimoto M, Nomura M (2014) Fundamental machining characteristics of ultrasonic assisted internal grinding of SiC ceramics. Mater Manuf Processes 29:557–563

Kanai K, Sugiyama K, Shiotani E, Nishimura K, Uchiyama J, Suzuki K, Inomata J, et al. (2010) Cylindrical internal surface with thermally spray coating

Shigeyuki Sömiya YI (2009) Silicon carbide ceramics-1 fundamental and solid reaction. Springer, Netherlands

Hall C, Tricard M, Murakoshi H, Yoko H (2005) New mold manufacturing techniques. Proc SPIE—Int Soc Optical Eng 5868:58680V

Agarwal S, Rao PV (2013) Predictive modeling of force and power based on a new analytical undeformed chip thickness model in ceramic grinding. Int J Mach Tool Manu 65:68–78

Nomura M. (2007) Study of ultrasonic vibration assisted internal grinding of small holes. Doctoral Dissertation Sendai, Japan: Tohoku University. (In Japanese)

Kumabe J (1961) Study on ultrasonic internal grinding by using the longitudinally vibrated grinding wheel: 1st report, traverse ultrasonic cutting. Trans Japan Soc Mech Eng 27:1404–1411

Kumabe J, Ito Y (1961) Study on ultrasonic internal grinding by using the longitudinally vibrated grinding wheel: 2nd report, the outline of the effects. Trans Japan Soc Mech Eng 27:1412–1418

Wu Y, Nomura M, Kato M, Tachibana T (2003) Study of internal ultrasonic vibration assisted grinding of small holes: construction of ultrasonic vibration spindle and its fundamental performances. J Japan Soc Grinding Eng 47:550–555

Fujimoto M, Wu Y, Cao J. High precision ultrasonically assisted internal grinding (uaig) of difficult-to-machining materials using metal bonded diamond wheels: Proceedings of International Conference on Leading Edge Manufacturing in 21st century : LEM21, 2011[C]

Zhang X, Arif M, Liu K, Kumar AS, Rahman M (2013) A model to predict the critical undeformed chip thickness in vibration-assisted machining of brittle materials. Int J Mach Tool Manu 69:57–66

Cheng J, Gong YD (2014) Experimental study of surface generation and force modeling in micro-grinding of single crystal silicon considering crystallographic effects. Int J Mach Tool Manu 77:1–15

Chen M, Zhao Q, Dong S, Li D (2005) The critical conditions of brittle–ductile transition and the factors influencing the surface quality of brittle materials in ultra-precision grinding. J Mater Process Tech 168:75–82

Golini D, Jacobs SD. Transition between brittle and ductile mode in loose abrasive grinding: San Dieg - DL Tentative, 1990[C]

Liang Z, Wang X, Wu Y, Xie L, Jiao L, Zhao W (2013) Experimental study on brittle–ductile transition in elliptical ultrasonic assisted grinding (EUAG) of monocrystal sapphire using single diamond abrasive grain. Int J Mach Tool Manu 71:41–51

Cao J, Wu Y, Lu D, Fujimoto M, Nomura M (2014) Material removal behavior in ultrasonic-assisted scratching of SiC ceramics with a single diamond tool. Int J Mach Tool Manu 79:49–61

Cao J, Wu Y, Li J, Zhang Q (2015) A grinding force model for ultrasonic assisted internal grinding (UAIG) of SiC ceramics. Int J Adv Manuf Technol 81:875–885

Cheng J, Yin G, Wen Q, Song H, Gong Y (2015) Study on grinding force modelling and ductile regime propelling technology in micro drill-grinding of hard-brittle materials. J Mater Process Technol 223:150–163

Wang Y, Lin B, Wang S, Cao X (2014) Study on the system matching of ultrasonic vibration assisted grinding for hard and brittle materials processing. Int J Mach Tool Manu 77:66–73

Arif M, Zhang X, Rahman M, Kumar S (2013) A predictive model of the critical undeformed chip thickness for ductile–brittle transition in nano-machining of brittle materials. Int J Mach Tool Manu 64:114–122

Bifano TG, Fawcett SC (1991) Specific grinding energy as an in-process control variable for ductile-regime grinding. Precis Eng 13:256–262

Slikkerveer PJ, Bouten PCP, Veld FHI, Scholten H (1998) Erosion and damage by sharp particles. Wear 217:237–250

Zarepour H, Yeo SH (2012) Predictive modeling of material removal modes in micro ultrasonic machining. Int J Mach Tool Manu 62:13–23

Marinescu ID.(2006) Handbook of machining with grinding wheels. CRC, Taylor & Francis,

Zhou X, Xi F (2002) Modeling and predicting surface roughness of the grinding process. Int J Mach Tool Manu 42:969–977

Shaw. (1972) New developments in grinding. Proceedings of the international grinding conference, Pittsburgh, Pennsylvania, April 18--20, 1972

Agarwal S, Rao PV (2012) Predictive modeling of undeformed chip thickness in ceramic grinding. Int J Mach Tool Manu 56:59–68

Liu D, Cong WL, Pei ZJ, Tang Y (2012) A cutting force model for rotary ultrasonic machining of brittle materials. Int J Mach Tools Manuf 52:77–84

Ghosh D, Subhash G, Radhakrishnan R, Sudarshan TS (2008) Scratch-induced microplasticity and microcracking in zirconium diboride–silicon carbide composite. Acta Mater 56:3011–3022

Chen JB, Fang QH, Wang CC, Du JK, Liu F (2016) Theoretical study on brittle–ductile transition behavior in elliptical ultrasonic assisted grinding of hard brittle materials. Precis Eng 46:104–117

Zhou M, Zhao P (2016) Prediction of critical cutting depth for ductile-brittle transition in ultrasonic vibration assisted grinding of optical glasses. Int J Adv Manuf Technol 86:1775–1784

Anderson D, Warkentin A, Bauer R (2011) Experimental and numerical investigations of single abrasive-grain cutting. Int J Mach Tool Manu 51:898–910

Acknowledgments

The authors would like to thank the support of the National Natural Science Foundation of China (No.51605024). The present work was also supported by the Fundamental Research Funds for the Central Universities (M17RC00020).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, J., Nie, M., Liu, Y. et al. Ductile-brittle transition behavior in the ultrasonic vibration-assisted internal grinding of silicon carbide ceramics. Int J Adv Manuf Technol 96, 3251–3262 (2018). https://doi.org/10.1007/s00170-018-1715-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1715-5