Abstract

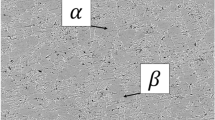

The main objective of this study is to investigate uncoated tungsten carbide tool wear mechanisms for high-pressure water-jet machining of the Ti555-3 titanium alloy. A comparative study has been undertaken (i.e. conventional versus assisted machining) based on numerous experimental tests. These tests have been accompanied by the measurement of the cutting forces and flank wear. It is concluded that the high-pressure water-jet assistance can greatly increase tool life compared to conventional machining, for all cutting conditions. The gain in tool life depends on the severity of the cutting condition. The analyses performed for each test (i.e. SEM, EDS and 3D profilometer) made it possible to monitor the tool wear and to investigate the main wear mechanisms. Based on these analyses, adhesion wear appears to be the most influential mechanism and it is accelerated by an increase in water-jet pressure. Monitoring of the wear profile made it possible to study the evolution of crater wear and material chipping during machining.

Similar content being viewed by others

References

Phapale K, Patil S, Kekade S, Jadhav S, Powar A, Supare A, Singh R (2016) Tool wear investigation in dry and high pressure coolant assisted machining of titanium alloy ti6al4v with variable α and β volume fraction. Procedia Manufacturing 6(Supplement C):154–159. 16th machining innovations conference for aerospace industry - MIC 2016

Ghosh A, Sivaprasad S, Bhattacharjee A, Kar SK (2013) Microstructure-fracture toughness correlation in an aircraft structural component alloy Ti-5Al-5V-5Mo-3Cr. Mater Sci Eng A 568:61–67

Nie XA, Hu Z, Liu HQ, Yi DQ, Chen TY, Wang BF, Gao Q, Wang DC (2014) High temperature deformation and creep behavior of Ti-5Al-5Mo-5V-1Fe-1Cr alloy. Mater Sci Eng A 613:306–316

Wagner V, Baili M, Dessein G (2015) The relationship between the cutting speed, tool wear, and chip formation during Ti-5553 dry cutting. Int J Adv Manuf Technol 76:893–912

Bai D, Sun J, Chen W, Wang T (2017) Wear mechanisms of WC/Co tools when machining high-strength titanium alloy TB6 (Ti-10V-2Fe-3Al). Int J Adv Manuf Technol 90:2863–2874

Arrazola P, Garay A, Iriarte L, Armendia M, Marya S, Maître FL (2009) Machinability of titanium alloys (Ti6Al4V and Ti555.3). J Mater Process Technol 209(5):2223–2230

Nouari M, Makich H (2013) Experimental investigation on the effect of the material microstructure on tool wear when machining hard titanium alloys: Ti-6Al-4V and Ti-555. Int J Refract Met Hard Mater 41:259–269

Ugarte A, M’Saoubi R, Garay A, Arrazola P (2012) Machining behaviour of Ti-6Al-4V and Ti-5553 alloys in interrupted cutting with PVD coated cemented carbide. Procedia CIRP 1:202–207. Fifth CIRP Conference on High Performance Cutting 2012

Chowdhury M, Chowdhury S, Yamamoto K, Beake B, Bose B, Elfizy A, Cavelli D, Dosbaeva G, Aramesh M, Fox-Rabinovich G, Veldhuis S (2017) Wear behaviour of coated carbide tools during machining of Ti6Al4V aerospace alloy associated with strong built up edge formation. Surf Coat Technol 313(Supplement C):319–327

Moura RR, da Silva MB, Machado ÁR, Sales WF (2015) The effect of application of cutting fluid with solid lubricant in suspension during cutting of Ti-6Al-4V alloy. Wear 332(Supplement C):762–771. 20th International Conference on Wear of Materials

Rashid RR, Sun S, Wang G, Dargusch M (2012) An investigation of cutting forces and cutting temperatures during laser-assisted machining of the Ti-6Cr-5Mo-5V-4Al beta titanium alloy. Int J Mach Tools Manuf 63:58–69

Rashid RR, Bermingham M, Sun S, Wang G, Dargusch M (2013) The response of the high strength Ti-10V-2Fe-3Al beta titanium alloy to laser assisted cutting. Precis Eng 37(2):461–472

Ayed Y, Germain G, Salem WB, Hamdi H (2014) Experimental and numerical study of laser-assisted machining of Ti6Al4V titanium alloy. Finite Elem Anal Des 92:72–79

Machai C, Biermann D (2011) Machining of β-titanium-alloy Ti-10V-2Fe-3Al under cryogenic conditions: cooling with carbon dioxide snow. J Mater Process Technol 211(6):1175–1183

Bordin A, Bruschi S, Ghiotti A, Bariani P (2015) Analysis of tool wear in cryogenic machining of additive manufactured Ti6Al4V alloy. Wear 328-329:89–99

Lv D, Xu J, Ding W, Fu Y, Yang C, Su H (2016) Tool wear in milling Ti40 burn-resistant titanium alloy using pneumatic mist jet impinging cooling. J Mater Process Technol 229:641–650

Shokrani A, Dhokia V, Newman ST (2016) Investigation of the effects of cryogenic machining on surface integrity in cnc end milling of Ti-6Al-4V titanium alloy. J Manuf Process 21(Supplement C):172–179

Ayed Y, Germain G, Melsio AP, Kowalewski P, Locufier D (2017) Impact of supply conditions of liquid nitrogen on tool wear and surface integrity when machining the Ti-6Al-4V titanium alloy. Int J Adv Manuf Technol 93:1199–1206

Courbon C, Kramar D, Krajnik P, Pusavec F, Rech J, Kopac J (2009) Investigation of machining performance in high-pressure jet assisted turning of Inconel 718: an experimental study. Int J Mach Tools Manuf 49(14):1114–1125

Kramar D, Krajnik P, Kopac J (2010) Capability of high pressure cooling in the turning of surface hardened piston rods. J Mater Process Technol 210(2):212–218

Machado AR, Wallbank J, Pashby IR, Ezugwu EO (1998) Tool performance and chip control when machining Ti6Al4V and Inconel 901 using high pressure coolant supply. Mach Sci Technol 2(1):1–12

da Silva RB, Machado AR, Ezugwu EO, Bonney J, Sales WF (2013) Tool life and wear mechanisms in high speed machining of Ti-6Al-4V alloy with PCD tools under various coolant pressures. J Mater Process Technol 213(8):1459–1464

Ezugwu EO, Bonney J, Silva RBD, Cakir O (2007) Surface integrity of finished turned Ti-6Al-4V alloy with PCD tools using conventional and high pressure coolant supplies. Int J Mach Tools Manuf 47(6):884–891

Da Silva RB, Sales WF, Costa ES, Ezugwu EO, Bonney J, Da Silva MB, Machado ÁR (2017) Surface integrity and tool life when turning of Ti-6Al-4V with coolant applied by different methods. Int J Adv Manuf Technol 93(5):1893–1902

da Silva RB, da Silva MB, Sales WF, Ezugwu EO, Machado ÁR (2016) Advances in the turning of titanium alloys with carbide and superabrasive cutting tools. In: Advanced materials in aerospace engineering, vol 1135 of advanced materials research. Trans Tech Publications, pp 234–254

Ayed Y, Germain G, Ammar A, Furet B (2013) Degradation modes and tool wear mechanisms in finish and rough machining of Ti17 titanium alloy under high-pressure water jet assistance. Wear 305(1-2):228–237

Ayed Y, Germain G, Ammar A, Furet B (2015) Tool wear analysis and improvement of cutting conditions using the high-pressure water-jet assistance when machining the Ti17 titanium alloy. Precis Eng 42:294–301

Kar SK, Suman S, Shivaprasad S, Chaudhuri A, Bhattacharjee A (2014) Processing-microstructure-yield strength correlation in a near β ti alloy, Ti-5Al-5Mo-5V-3Cr. Mater Sci Eng A 610(Supplement C):171–180

Matsumoto H, Kitamura M, Li Y, Koizumi Y, Chiba A (2014) Hot forging characteristic of Ti-5Al-5V-5Mo-3Cr alloy with single metastable β microstructure. Mater Sci Eng A 611(Supplement C):337–344

Odelros S, Kaplan B, Kritikos M, Johansson M, Norgren S (2017) Experimental and theoretical study of the microscopic crater wear mechanism in titanium machining. Wear 376(Part A):115–124. 21st International Conference on Wear of Materials

Kong J, Xia Z, Xu D, He N (2016) Investigation on notch wear mechanism in finish turning pure iron material with uncoated carbide tools under different cooling/lubrication conditions. Int J Adv Manuf Technol 86:97–105

Chandrasekaran H, Johansson J (1994) Chip flow and notch wear mechanisms during the machining of high austenitic stainless steels. CIRP Ann 43(1):101–105

Kasim M, Haron CC, Ghani J, Sulaiman M, Yazid M (2013) Wear mechanism and notch wear location prediction model in ball nose end milling of Inconel 718. Wear 302(1):1171–1179. Wear of Materials 2013

Astakhov V (2004) The assessment of cutting tool wear. Int J Mach Tools Manuf 44(6):637–647

Kikuchi M (2009) The use of cutting temperature to evaluate the machinability of titanium alloys. Acta Biomater 5(2):770–775

Acknowledgements

Authors would like to thank the company Timet (Ugine-France) for the material support given to this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ayed, Y., Germain, G. High-pressure water-jet-assisted machining of Ti555-3 titanium alloy: investigation of tool wear mechanisms. Int J Adv Manuf Technol 96, 845–856 (2018). https://doi.org/10.1007/s00170-018-1661-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1661-2