Abstract

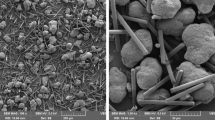

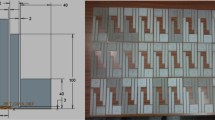

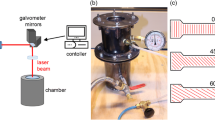

Selective laser sintering (SLS) is a modern rapid prototyping method with which 3D objects with complex geometries can be manufactured precisely through the sintering of powders’ thin layers using the laser power. The effective manufacturing parameters in SLS are laser power, scanning speed, scan-spacing, and the part-bed temperature. In this work, selective laser sintering (SLS) is used to manufacture a composite material from white cement additives and polyamide 12 (PA12) and then, the influence of energy density (controlled by laser power, scanning speed, and scan-spacing) on the dimensions, density, mechanical properties, and morphology of sintered specimens is investigated. The criteria for obtaining optimum manufacturing parameters are the part dimensional accuracy, maximum density, and maximum strength. Hence, the optimum energy density for producing parts with maximum density and enhanced strength has been determined experimentally. The tensile, compressive, and flexural testing methods are used to evaluate the effects of laser power on the fabricated parts. The results show that the optimum energy density of 0.051 J/mm2 could achieve the highest density of sintered parts without any degradation of binder material. Also, it is found that a combination of a 0.051-J/mm2 energy density and 10% weight fraction of white cement is sufficient enough to enforce significant improvements on the mechanical properties of PA12-sintered specimens.

Similar content being viewed by others

References

Kai CC, Fai LK (1997) Rapid prototyping: principles & applications in manufacturing. Wiley, New York

Pham DT, Dimov SS (2000) Rapid manufacturing: the technologies and applications of rapid prototyping and rapid tooling. Springer, London

Pham DT, Dimov SS (2003) Rapid prototyping and rapid tooling—the key enablers for rapid manufacturing. Proc Inst Mech Eng C J Mech 217(1):1–23. https://doi.org/10.1243/095440603762554569

Kumar V, Dutta D (1997) An assessment of data formats for layered manufacturing. Adv Eng Softw 28(3):151–164. https://doi.org/10.1016/S0965-9978(96)00050-6

Yusoff WY (2007) An investigation of the orange peel phenomenon. Dissertation, Cardiff University

Neal PJ (1994) Rapid prototyping using the selective laser sintering process. Assem Autom 14(2):14–17. https://doi.org/10.1108/01445159410102364

Vail NK, Balasubramanian B, Barlow JW, Marcus HL (1996) A thermal model of polymer degradation during selective laser sintering of polymer coated ceramic powders. Rapid Prototyp J 2(3):24–40. https://doi.org/10.1108/13552549610129764

Hon KB, Gill TJ (2003) Selective laser sintering of SiC/polyamide composites. CIRP Ann Manuf Technol 52(1):173–176. https://doi.org/10.1016/S0007-8506(07)60558-7

Maeda K, Childs TC (2004) Laser sintering (SLS) of hard metal powders for abrasion resistant coatings. J Mater Process Technol 149(1-3):609–615. https://doi.org/10.1016/j.jmatprotec.2004.02.024

Gill TJ, Hon KB (2004) Experimental investigation into the selective laser sintering of silicon carbide polyamide composites. Proc Inst Mech Eng B J Eng 218(10):1249–1256. https://doi.org/10.1243/0954405042323487

Laumer T, Stichel T, Sachs M, Amend P, Schmidt M (2013) Quantification and modification of new polymer powders for laser beam melting using Ulbricht spheres, high value manufacturing: advanced research in virtual and rapid prototyping. Proceedings of the 6th International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 1-5 October

Ajoku U, Saleh N, Hopkinson N, Hague R, Erasenthiran P (2006) Investigating mechanical anisotropy and end-of-vector effect in laser-sintered nylon parts. Proc Inst Mech Eng B J Eng 220(7):1077–1086. https://doi.org/10.1243/09544054JEM537

Lea FM (1970) The chemistry of cement and concrete, 3rd edn. Edward Arnold Ltd, Glasgow

Parnes P (1983) Structure and performance of cements. Applied Science, London

Shirley DE (1986) Introduction to concrete, 3rd edn. Cement and Concrete Association, Slough

Frenkel J (1945) Viscous flow of crystalline bodies under the action of surface tension. J Phys USSR 9:385–391

Caulfield B, McHugh PE, Lohfeld S (2007) Dependence of mechanical properties of polyamide components on build parameters in the SLS process. J Mater Process Technol 182(1-3):477–488. https://doi.org/10.1016/j.jmatprotec.2006.09.007

Unal H (2004) Morphology and mechanical properties of composites based on polyamide 6 and mineral additives. Mater Des 25(6):483–487. https://doi.org/10.1016/j.matdes.2004.01.007

He D, Jiang B (1993) The elastic modulus of filled polymer composites. J Appl Polym Sci 49(4):617–621. https://doi.org/10.1002/app.1993.070490408

Acknowledgements

The parts were fabricated at the Manufacturing Engineering Centre in the University of Cardiff (UK); the author would like to thank Professor Duc Truong Pham for the kind support through all the manufacturing processes. Also, the specimens were tested at Mechanical Engineering Laboratories in the University of Cardiff; the author is extremely grateful to their kind support of this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aldahash, S.A. Optimum manufacturing parameters in selective laser sintering of PA12 with white cement additives. Int J Adv Manuf Technol 96, 257–270 (2018). https://doi.org/10.1007/s00170-018-1584-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1584-y