Abstract

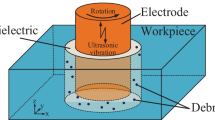

Micro-electro discharge machining (EDM) has a crucial role in fabrication of parts such as molds. One of the most challenging aspects of EDM process relates to flushing of debris. Increasing the material removal rate causes significant enhancement in EDM process. In this study, new numerical approach for enhancing flushing is proposed. A model of vibratory electrode and dielectric flow pattern is validated with theoretical and experimental results. Next, the effect of vibratory electrode geometry and its material properties on flushing of debris is investigated. To this end, design of experiment method is applied to find optimum vibratory electrode shape and material. At first step, vibrational analysis is performed for electrodes to find mode shapes and their corresponding frequency utilizing the finite element method. Vibrational results have good agreement with theoretical ones that are presented in literatures. Next, frequency response function analysis is done for vertical excitation force to find out displacements of electrodes in longitudinal modes. The results of these simulations are utilized to construct 3D computational fluid dynamic (CFD) models to find velocity distribution on gap space between electrode and work piece. Full factorial design is used to evaluate electrode’s parameters. The results from these simulations are studied to achieve best electrode shape that is able to flush the gap flow significantly. Finally, dielectric flow regime for optimum electrode shape is surveyed.

Similar content being viewed by others

References

D’Urso G, Quarto M, Ravasio C (2017) A model to predict manufacturing cost for micro-EDM drilling. Int J Adv Manuf Technol 91:2843

Shabgard MR, Gholipoor A, Baseri H (2016) A review on recent developments in machining methods based on electrical discharge phenomena. Int J Adv Manuf Technol 87:2081

Hourmand M, Sarhan AAD, Sayuti M (2017) Micro-electrode fabrication processes for micro-EDM drilling and milling: a state-of-the-art review. Int J Adv Manuf Technol 91:1023

Maher I, Sarhan AAD, Hamdi M (2015) Review of improvements in wire electrode properties for longer working time and utilization in wire EDM machining. Int J Adv Manuf Technol 76:329–351

Grigoriev SN, Kozochkin MP, Kropotkina EY, Okunkova AA (2016) Study of wire tool-electrode behavior during electrical discharge machining by vibroacoustic monitoring. Mech Ind 17(7):717

Enache S, Opran C, Stoica G, Strajescu E (1990) The study of EDM with forced vibration of tool-electrode. CIRP Ann Manuf Technol 39(1):167–170

Radhakrishnan P, Vijayaraghavan L (2017) Assessment of material removal capability with vibration-assisted wire electrical discharge machining. J Manuf Process 26:323–329

Habib S, Okada A (2016) Experimental investigation on wire vibration during fine wire electrical discharge machining process. Int J Adv Manuf Technol 84:2265–2276

Lee PA, Kim Y, Kim BH (2015) Effect of low frequency vibration on micro EDM drilling. Int J Precis Eng Manuf 16:2617–2622

Singh J, Satsangi PS, Walia RS, Singh VP (2011) Micro-hardness and machined surface damage study for continuous and discontinuous ultrasonic vibration assisted electrical discharge machining. Mater Manuf Process. https://doi.org/10.1080/10426914.2011.585502

Cetin S, Okada A, Uno Y (2004) Effect of debris accumulation on machining speed in EDM. Int J Electr Mach 9:9–14

Masuzawa T, Cui X, Taniguchi N (1992) Improved jet flushing for EDM. Ann CIRP 41(1):239–242

Okada A, Uno Y, Onoda S, Habib S (2009) Computational fluid dynamics analysis of working fluid flow and debris movement in wire EDMed kerf. CIRP Ann 58(1):209–212

Li L, Gu L, Xi X et al (2012) Influence of flushing on performance of EDM with bunched electrode. Int J Adv Manuf Technol 58(1):187–194

Maity K, Choubey M (2016) Modeling and process simulation of vibration assisted workpiece in micro-EDM using FEM. World J Eng 13(3):242–250

William TT, & Marie DD (1998) Theory of vibration with applications. New Jersey

Shih TH, Liou WW, Shabbir A, Yang Z, Zhu J (1995) A new ss eddy-viscosity model for high Reynolds number turbulent flows—model development and validation. Comput Fluids 24(3):227–238

Okada A, Uno Y, Onoda S, Habib S (2009) Computational fluid dynamics analysis of working fluid flow and debris movement in wire EDMed kerf. CIRP Ann Manuf Technol 58(1):209–212

Acknowledgment

The authors would like to express their gratitude to Automotive Industries Research & Innovation Center (AIRIC) of SAIPA, for valuable support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Beigmoradi, S., Ghoreishi, M. & Vahdati, M. Optimum design of vibratory electrode in micro-EDM process. Int J Adv Manuf Technol 95, 3731–3744 (2018). https://doi.org/10.1007/s00170-017-1428-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1428-1