Abstract

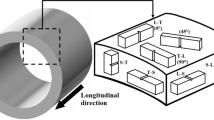

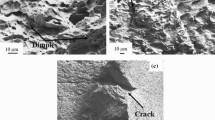

The present work is an investigation on the effect of mechanical surface treatment using ball burnishing technique on fracture toughness in spiral API X70 pipeline steel. The burnishing operation has been carried out on three series of impact API 5L 45 Ed specimens that have been prepared according to the location of the notch towards the weld bed: BM notched specimens, FZ notched specimens, and HAZ notched specimens. In the untreated specimens, the absorbed energy in BM specimens is higher than the energy found in FZ and HAZ through the testing temperature range of 50 to −40 °C. In surface-treated specimens, there has been a significant change in the three curves of absorbed energy versus temperature. This is observed when testing temperature decrease from 20 to −40 °C since the energy in BM specimens dropped drastically reaching values lower than that obtained for FZ and HAZ specimens. At the temperature range 50 to 20 °C, the absorbed energy in ball-burnished specimens is relatively higher. At lower testing temperatures below −40 °C, the absorbed energy converged to the same value. At room temperature, hardness tests indicate that where the absorbed energy is higher, hardness is lower.

Similar content being viewed by others

References

Zelmati D, Ghelloudj O, Amirat A (2016) Reliability estimation of pressurized API 5L X70 pipeline steel under longitudinal elliptical corrosion defect. Int J AdvManuf Technol. https://doi.org/10.1007/s00170-016-9580-6

Richards, F. (2013). Failure analysis of a natural gas pipeline rupture, 653–657. https://doi.org/10.1007/s11668-013-9745-7

Yang X, Xu Y, Tan X, Wu D (2014) Influences of crystallography and delamination on anisotropy of Charpy impact toughness in API X100 pipeline steel. Mater Sci Eng A 607:53–62. https://doi.org/10.1016/j.msea.2014.03.121

Yang X, Xu Y, Tan X, Wu D (2015) Relationships among crystallographic texture, fracture behavior and Charpy impact toughness in API X100 pipeline steel. Mater Sci Eng A 641, 96:–106. https://doi.org/10.1016/j.msea.2015.06.029

Chen, X., Lu, H., Chen, G., and Wang, X. (2015). A comparison between fracture toughness at different locations of longitudinal submerged arc welded and spiral submerged arc welded joints of API X80 pipeline steels, Department of Mechanical and Aerospace Engineering, Carleton University, Ottawa, ENGINEERING FRACTURE MECHANICS. https://doi.org/10.1016/j.engfracmech.2015.09.003

Hwang B, Shin SY, Lee S, Kim NJ, Kim S, Kang KB (2006) Correlation of crack-tip opening angle for stable crack propagation with Charpy and drop-weight tear test properties in high-toughness API X70 pipeline steels. Metall Mater Trans A Phys Metall Mater Sci 37(2):371–380. https://doi.org/10.1007/s11661-006-0007-0

Yong, S., Hwang, B., Kim, S., and Lee, S. (2006). Fracture toughness analysis in transition temperature region of API X70 pipeline steels, 429, 196–204. https://doi.org/10.1016/j.msea.2006.05.086

Shin SY, Gong G, Kim S, Lee S (2007) Analysis of fracture toughness in the transition temperature region of API X70 pipeline steels rolled in two-phase region. Metall Mater Trans A Phys Metall Mater Sci 38(5):1012–1021. https://doi.org/10.1007/s11661-007-9125-6

Materials, E. (2009). On the relation of microstructure and impact toughness characteristics of DSAW steel of grade API X70. Fatigue Fract Eng Mater Struct, 33–40. https://doi.org/10.1111/j.1460-2695.2008.01312.x

Park D, Gravel J (2015) Fracture toughness measurements using two single-edge notched bend test methods in a single specimen. Eng Fract Mech 144:78–88. https://doi.org/10.1016/j.engfracmech.2015.06.033

Maheshwari, A. S., and Gawande, R. R. (2017). Influence of specially designed high-stiffness ball burnishing tool on surface quality of Titanium alloy. Materials Today: Proceedings, ScienceDirect 4(2), 1405–1413. https://doi.org/10.1016/j.matpr.2017.01.162

Liu, Z. Y., Fu, C. H., Sealy, M. P., Zhao, Y., and Guo, Y. B. (2017). Benchmark burnishing with Almen strip for surface integrity, 10, 456–466.https://doi.org/10.1016/j.promfg.2017.07.027

Shiou F, Huang S, Shih AJ, Zhu J, Yoshino M (2017) Fine surface finish of a hardened stainless steel using a new burnishing tool. Proc Manuf 10:208–217. https://doi.org/10.1016/j.promfg.2017.07.048

Yuan X, Sun Y, Li C, Liu W (2017) Experimental investigation into the effect of low plasticity burnishing parameters on the surface integrity of TA2. Int J Adv Manuf Technol:1089–1099. https://doi.org/10.1007/s00170-016-8838-3

Hamadache, H., Zemouri, Z., Laouar, L., and Dominiak, S. (2014). Improvement of surface conditions of 36 Cr Ni Mo 6 steel by ball burnishing process, 28(4), 1491–1498. https://doi.org/10.1007/s12206-014-0135-1

Chomienne V, Valiorgue F, Rech J, Verdu C (2016) Influence of ball burnishing on residual stress profile of a 15-5PH stainless steel. CIRP J Manuf Sci Technol. https://doi.org/10.1016/j.cirpj.2015.12.003

Amdouni H, Bouzaiene H, Montagne A, Van Gorp A, Coorevits T, Nasri M, Iost A (2016) Experimental study of a six new ball-burnishing strategies effects on the Al-alloy flat surfaces integrity enhancement. Int J AdvManuf Technol. https://doi.org/10.1007/s00170-016-9529-9

Korhonen H, Laakkonen J, Hakala J, Lappalainen R (2013) Improvements in the surface characteristics of stainless steel work pieces by burnishing with an amorphous diamond-coated tip. Mach Sci Technolo 17:593–610

Devaraya, G., Shetty, R., and Srinivas, S. (2016). Wear resistance enhancement of titanium alloy (Ti–6Al–4V ) by ball burnishing process. Integrative Medicine Research, (x x). https://doi.org/10.1016/j.jmrt.2016.03.007

Grocha D, Berczy S, Grz Z (2017) Modeling of burnishing thermally toughened X42CrMo4 steel with a ceramic ZrO 2 ball. ScienceDirect 7:2–9. https://doi.org/10.1016/j.acme.2017.04.009

Avilés, R., Albizuri, J., Rodríguez, A., and De Lacalle, L. N. L (2013). Influence of low-plasticity ball burnishing on the high-cycle fatigue strength of medium carbon AISI 1045 steel, 55, 230–244. https://doi.org/10.1016/jijfatigue201306024

Yuan X, Sun Y, Li C (2017) An engineering high cycle fatigue strength prediction model for low plasticity burnished samples. Int J Fatigue. https://doi.org/10.1016/j.ijfatigue.2017.06.013

Okada M, Shinya M, Matsubara H, Kozuka H, Otsu M (2017) Development and characterization of diamond tip burnishing with a rotary tool. J Mater Process Technol 244:106–115

Shiou, F., and Banh, Q. (2016). Development of an innovative small ball-burnishing tool embedded with a load cell, (43). https://doi.org/10.1007/s00170-016-8413-y

He, D., Wang, B., Zhang, J., Liao, S., and Deng, W. J. (2017). Investigation of interference effects on the burnishing process. https://doi.org/10.1007/s00170-017-0640-3

Hiegemann L, Weddeling C, Tekkaya AE (2016) Analytical contact pressure model for predicting roughness of ball burnished surfaces. J Mater Process Tech. https://doi.org/10.1016/j.jmatprotec.2016.01.024

Acknowledgments

The authors would like to thank the metallurgy laboratory of Badji Mokhtar University Annaba for specimen preparation, hardness measurements, and metallographic observations. Thanks are due to the staff of mechanical laboratory of Alfapipe of the Algerian steel company in El-Hadjar, Annaba, for the furniture of the material and the preparation of tensile and impact specimens and also conducting the corresponding mechanical tests. Thanks to URASM, the applied research unit in welding and metallurgy of Annaba, for analyzing the composition of the material. A great thank to ENSMM, the Algerian national high school of mining and metallurgy in Annaba, for their contribution in SEM observations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bounouara, A., Hamadache, H. & Amirat, A. Investigation on the effect of ball burnishing on fracture toughness in spiral API X70 pipeline steel. Int J Adv Manuf Technol 94, 4543–4551 (2018). https://doi.org/10.1007/s00170-017-1181-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1181-5