Abstract

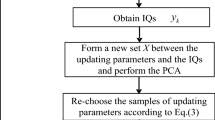

The numerical forecasting of car body construction processes is already being used in industry to provide support in the ramp-up process. However, long calculation times are stretching the finite element method (FEM) to the limit, in particular when analyzing the effect of the variation of an input variable on one or more dependent variables. Moreover, there is still a need for experienced users to separate relevant from irrelevant parameters and to determine their variation. This paper presents a method that makes it possible, based on stochastic experimental design (DOE) in combination with both principle component analysis (PCA) and singular value decomposition (SVD), to create mathematical models that separate relevant from irrelevant input variables and that represent the effect of individual variables on all part or assembly areas by means of a variance-based sensitivity analysis. The method is verified in a case study based on realistic front hood geometry. The study examines the deep-drawing process steps as well as the geometrical accuracy in a measuring device. It is shown that it is possible to represent the effects of the most important variables from these processes on the strain and geometry parameters of the car body part and to vary these, based on a model function, interactively.

Similar content being viewed by others

References

Hu M, Lin Z, Lai X et al (2001) Simulation and analysis of assembly processes considering compliant, non-ideal parts and tooling variations. Int J Mach Tools Manuf 41(15):2233–2243. https://doi.org/10.1016/S0890-6955(01)00044-X

Long Y, Hu SJ (1998) A unified model for variation simulation of sheet metal assemblies. In: ElMaraghy HA (ed) Geometric Design Tolerancing: Theories, Standards and Applications. Springer US, Boston, pp 208–219

Schulte S (1999) Umformsimulation als fester Bestandteil des Produktentstehungsprozesses bei Audi. In: Doege E (ed) 16. Umformtechnischen Kolloquium, Hannover 25. und 26. HFF, Hannover, pp 263–277

Li E (2013) Reduction of springback by intelligent sampling-based LSSVR metamodel-based optimization. Int J Mater Form 6(1):103–114. https://doi.org/10.1007/s12289-011-1076-1

Roll K, Lemke T, Wiegand K (2004) Simulationsgestützte Kompensation der Rückfederung. Procedia of 3. LS-DYNA Anwenderforum: A-I-1 - A-I-13

Großmann K, Ulbricht V, Hartmann A et al. (2007) Vergleichende Bewertung der Simulation von Umformprozessen mit elastischen Randbedingungen: Ergebnisse eines Vorhabens der Industriellen Gemeinschaftsforschung (IGF) …; Abschlussbericht 2007. EFB-Forschungsbericht, vol 264. EFB, Hannover

Ackert P, Schwarz C, Müller J et al (2015) New approach for measurement & simulation in sheet metal forming. GOM Conference, Braunschweig

Lee JD, Haynes LS (1987) Finite-element analysis of flexible fixturing system. J Eng Ind 109(2):134–139. https://doi.org/10.1115/1.3187103

Landgrebe D, Ackert P, Grützner R et al (2015) Improving the ramp-up process of a body-construction line by numerical supported design of clamping devices and FEM based tolerance prognosis. Key Eng Mater 651-653:932–937. https://doi.org/10.4028/www.scientific.net/KEM.651-653.932

Siekirk JF (1986) Process variable effects on sheet metal quality. J Appl Metalwork 4(3):262–269. https://doi.org/10.1007/BF02833934

Zhang ZT, Pitt G, King A et al. (1998) Stamping part surface quality improvement through process optimization. SAE technical paper series 980073. doi: https://doi.org/10.4271/980073

Majeske KD, Hammet PC (2003) Identifying sources of variation in sheet metal stamping. Int J Flex Manuf Syst 15(1):5–18. https://doi.org/10.1023/A:1023993806025

Naceur H, Guo YQ, Ben-Elechi S (2006) Response surface methodology for design of sheet forming parameters to control springback effects. Comput Struct 84(26–27):1651–1663. https://doi.org/10.1016/j.compstruc.2006.04.005

Wei L, Yuying Y, Zhongwen X et al (2009) Springback control of sheet metal forming based on the response-surface method and multi-objective genetic algorithm. Mater Sci Eng A 499(1–2):325–328. https://doi.org/10.1016/j.msea.2007.11.121

Meinhardt J, Grossenbacher K, Ganser M et al. (2007) Neue Wege zum wirtschaftlichen Leichtbau: Innovative Lösungen zur Blechumformung und mechanischen Fügetechnik; Tagungsband des EFB-Kolloquiums Blechverarbeitung 2007 am 6. und 7. März 2007 in Fellbach. Tagungsband / Europäische Forschungsgesellschaft für Blechverarbeitung e.V, T 27. Europäische Forschungsges. für Blechverarbeitung e.V. (EFB), Hannover

Emrich A, Liewald M, Ruf G (2012) Increasing press shop productivity and quality by the means of robustness analysis in the die engineering phase. Mini-Symposium: Robust Design in Forming Technology, IJmuiden

Wärmefjord K, Söderberg R, Ottosson P et al. (2013) Prediction of geometrical variation of forged and stamped parts for assembly variation simulation. In: Hora P (ed) Proceedings of iddrg Conference 2013: Conference 2013, Zurich, Switzerland, June 2–5, 2013. Institute of Virtual Manufacturing ETH Zurich, Zürich, pp 99–104

Wolff S (2015) Robustness analysis of metal forming simulation – state of the art in practice. In: Landgrebe D, Drossel W, Putz M (eds) 5th international conference on accuracy in forming technology: ICAFT 2015, 22nd SFU 2015: proceedings. Verlag Wissenschaftliche Scripten, Auerbach, pp 319–334

Gerbino S, Kriechenbauer S, Franciosa F et al (2015) Understanding whole shape variability of stamped sheet metal parts for root cause analysis. In: Landgrebe D, Drossel W, Putz M (eds) 5th international conference on accuracy in forming technology: ICAFT 2015, 22nd SFU 2015: proceedings. Auerbach, Verlag Wissenschaftliche Scripten, pp 423–438

Youcef-Toumi K, Liu WS, Asada H (1988) Computer-aided analysis of reconfigurable fixtures and sheet metal parts for robotic drilling. Robot Comput Integr Manuf 4(3–4):387–394. https://doi.org/10.1016/0736-5845(88)90009-9

Franciosa P, Gerbino S, Ceglarek D (2016) Fixture capability optimisation for early-stage design of assembly system with compliant parts using nested polynomial chaos expansion. Procedia CIRP 41:87–92. https://doi.org/10.1016/j.procir.2015.12.101

Schwarz C, Ackert P, Rössinger M et al. (2015) Mathematical optimization of clamping processes in car-body production. 12th optimization and stochastic days, Weimar https://www.dynardo.de/fileadmin/Material_Dynardo/bibliothek/WOST12/22_WOST2015_Session6_Schwarz_Paper.pdf

Johnson RA, Wichern DW (2002) Applied multivariate statistical analysis, 5th edn. Prentice Hall, Upper Saddle River, NJ

Pearson K (1901) On lines and planes of closest fit to systems of points in space. Philosophical Magazin 2:559–572

Hotelling H (1933) Analysis of a complex of statistical variables into principal components. J Educ Psychol 24(6):417–441. https://doi.org/10.1037/h0071325

Jolliffe IT (2004) Principal component analysis, 2. ed., [Nachdr.]. Springer series in statistics. Springer, New York

Golub G, Kahan W (1965) Calculating the singular values and pseudo-inverse of a matrix. J Soc Ind Appl Math Ser B Numer Anal 2(2):205–224. https://doi.org/10.1137/0702016

Reris R, Brooks JP (2015) Principal component analysis and optimization: a tutorial. Proceedings of 14th INFORMS computing society conference 2015: 212–225. doi: https://doi.org/10.1287/ics.2015.0016

Madsen RE, Hansen LK, Winther O (2004) Singular value decomposition and principal component analysis. Neural Netw 1:1–5

Saltelli A (2004) Sensitivity analysis in practice: a guide to assessing scientific models. John Wiley & Sons Ltd., Hoboken

Saltelli A, Ratto M, Andres T et al (2008) Global sensitivity analysis: the primer. John Wiley & Sons Ltd., Chichester, Hoboken

Cukier IR, Levine HB, Shuler EK (1978) Nonlinear sensitivity analysis of multiparameter model systems. J Comput Phys 26(1):1–42

Cukier IR, Fortuin MC, Shuler EK et al (1973) Study of the sensitivity of coupled reaction systems to uncertainties in rate coefficients. I Theory. J Chem Phys 59:3873–3878

Sobol IM (1993) Sensitivity estimates for nonlinear mathematical models. Math Model Comput Exp 1:407–414

Homma T, Saltelli A (1996) Importance measures in global sensitivity analysis of nonlinear models. Reliab Eng Syst Saf 52(1):1–17. https://doi.org/10.1016/0951-8320(96)00002-6

Saltelli A, Annoni P, Campolongo F et al (2010) Variance based sensitivity analysis of model output - design and estimator for the total sensitivity index. Comput Phys Commun 181:259–270

Saltelli A (2002) Making best use of model evaluations to compute sensitivity indices. Comput Phys Commun 145(2):280–297. https://doi.org/10.1016/S0010-4655(02)00280-1

Saltelli A, Annoni P (2010) How to avoid a perfunctory sensitivity analysis. Environ Model Softw 25(12):1508–1517. https://doi.org/10.1016/j.envsoft.2010.04.012

Montgomery DC, Runger GC (2003) Applied statistics and probability for engineers, 3rd edn. Wiley, New York, Chichester

Berry B (1996) Inside the stamping press, where the costs are. New Steel 12(6):22–35

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Schwarz, C., Ackert, P. & Mauermann, R. Principal component analysis and singular value decomposition used for a numerical sensitivity analysis of a complex drawn part. Int J Adv Manuf Technol 94, 2255–2265 (2018). https://doi.org/10.1007/s00170-017-0980-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0980-z