Abstract

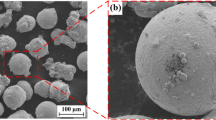

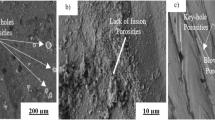

Laser forming of pure aluminum closed-cell foam has been studied by means of an effective and cellular model, and the results are compared with experiments and numerical simulations. In order to reveal the forming process and bending mechanism during the process of laser forming closed-cell foam aluminum, a simulation was performed. It is the first time to study the laser forming pure aluminum closed-cell foam aluminum when compared to Al-Si closed-cell foam aluminum. It is found that the bending angle increases with increasing the laser power, and decreases with the increasing scan velocity in the experiment results. The stress/strain profile is similar to that in laser forming Al-Si foam aluminum in simulation results. It is confirmed that temperature gradient mechanism (TGM) is the dominant mechanism during the present laser forming of the closed-cell pure aluminum foam material. And the plastic compressive strain is caused by overall response of the cell wall bending and cell bucking, not by the material shortening.

Similar content being viewed by others

References

Raj RE, Daniel BSS (2008) Manufacturing challenges in obtaining tailor-made closed-cell structures in metallic foams. Int J Adv Manuf Technol 38(5–6):605–612. https://doi.org/10.1007/s00170-007-1254-y

Guglielmotti A, Quadrini F, Squeo EA, Tagliaferri V (2009) Laser bending of aluminum foam sandwich panels. Adv Eng Mater 11(11):902–906. https://doi.org/10.1002/adem.200900111

Quadrini F, Guglielmotti A, Squeo EA, Tagliaferri V (2010) Laser forming of open-cell aluminium foams. J Mater Process Technol 210(11):1517–1522. https://doi.org/10.1016/j.jmatprotec.2010.04.010

Loredana S, Guglielmotti A and Quadrini F, (2010) Formability of open-cell aluminium foams by laser. Paper presented at the Proceedings ASME. 2010 International Manufacturing Science and Engineering Conference MSEC2010, Erie, Pennsylvania

Quadrini F, Denise B, Daniele F, Loredana S, Satrsiero A (2013) Numerical simulation of laser bending of aluminum foams. Key Eng Mater 2013(554–557):1864–1871. https://doi.org/10.4028/www.scientific.net/KEM.554-557.1864

Zhang M, Chen CJ, Grandal G, Bian DK, Yao YL (2016) Experimental and numerical investigation of laser forming of closed-cell aluminum foam. J Manuf Sci Eng 138(2):021006–021006-8. https://doi.org/10.1115/1.4030511

Tizian B, Christopher B, Zhang M, Chen CJ, Lawrence YL (2016) Effect of geometrical modeling on prediction of laser-induced heat transfer in metal foam. J Manuf Sci Eng 138(12):121008–121008-11. https://doi.org/10.1115/1.4033927

Mukarami T, Tsumura T, Ikeda T, Nakajima H, Nakata K (2007) Ansitropic fusion profile and joint strength of lotus-type porous magnesium by laser welding. Mater Sci Eng A 456(1–2):278–285. https://doi.org/10.1016/j.msea.2006.11.162

Yilbas BS, Akhtar SS, Keles O (2013) Laser cutting of aluminum foam: experimental and model studies. J Manuf Sci Eng 135(5):051018–051026-9. https://doi.org/10.1115/1.4025009

Deshpande VS, Fleck NA (2000) Isotropic constitutive models for metallic foams. J Mech Phys Solids 48(6–7):1253–1283. https://doi.org/10.1016/S0022-5096(99)0082-4

ABAQUS Theory manual, version 6.9, 2009, ABAQUS Inc., Pawtucket

Cheng P, Fan YJ, Lawrence YL, Mika DP, Zhang WW, Graham M, Marte J, Jones M (2005) Laser forming of varying thickness plate—part1: process analysis. J Manuf Sci Eng 128(3):642–650. https://doi.org/10.1115/1.2162912

Tzeng SC, Ma WP (2006) A novel approach to manufacturing and experimental investigation of closed-cell Al foams. Int J Adv Manuf Technol 28(11–12):1122–1128. https://doi.org/10.1007/s00170-004-2440-9

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, M., Chen, C., Huang, Y. et al. Bending processing and mechanism of laser forming pure aluminum metal foam. Int J Adv Manuf Technol 94, 1849–1856 (2018). https://doi.org/10.1007/s00170-017-0976-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0976-8