Abstract

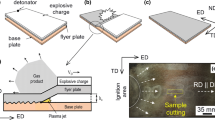

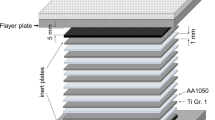

Ti/Ni alloy-based laminate composite materials were produced by explosive welding with two thin intermediate layers of tantalum and copper placed between Ti and Ni alloy layers. The influence of the thickness of the Cu interlayer (0.1–0.7 mm) on the structure and mechanical properties of the explosively welded composites was examined. Investigations carried out by optical and scanning electron microscopy showed the formation of an inhomogeneous structure in the vicinity of the interfaces with zones of local melting and cavities within these zones. The wavelength and the amplitude at the interface between the copper and tantalum interlayers changed with the thickness of the copper layer. In order to evaluate the mechanical properties of the composites containing copper interlayers of different thicknesses, microhardness, tensile, and bending tests were performed. As the thickness of the copper layer was decreased to 0.3 mm, the tensile and bending strengths of the laminate composites increased.

Similar content being viewed by others

References

Bataev IA, Bataev AA, Mali VI, Pavliukova DV (2012) Structural and mechanical properties of metallic-intermetallic laminate composites produced by explosive welding and annealing. Mater Design 35:225–234. doi:10.1016/j.matdes.2011.09.030

Miriyev A, Barlam D, Shneck R, Stern A, Frage N (2014) Steel to titanium solid state joining displaying superior mechanical properties. J Mater Process Tech 214(12):2884–2890. doi:10.1016/j.jmatprotec.2014.06.026

Dai X, Zhang H, Liu J, Feng J (2015) Microstructure and properties of Mg/Al joint welded by gas tungsten arc welding-assisted hybrid ultrasonic seam welding. Mater Design 77:65–71. doi:10.1016/j.matdes.2015.03.054

Bataev IA, Hokamoto K, Keno H, Bataev AA, Balagansky IA, Vinogradov AV (2015) Metallic glass formation at the interface of explosively welded Nb and stainless steel. Met Mater Int. doi:10.1007/s12540-015-5020-7

Nishida M, Chiba A, Morizono Y, Matsumoto M, Murakami T, Inoue A (1995) Formation of nonequilibrium phases at collision interface in an explosively welded Ti/Ni clad. Mater T JIM 36(11):1338–1343

Fuji A, Horiuchi Y, Yamamoto K (2005) Friction welding of pure titanium and pure nickel. Sci Technol Weld Joi 10(3):287–294. doi:10.1179/174329305X40598

Chatterjee S, Abinandanan TA, Chattopadhyay K (2008) Phase formation in Ti/Ni dissimilar welds. Mat Sci Eng-A 490(1–2):7–15. doi:10.1016/j.msea.2007.12.041

Chatterjee S, Abinandanan TA, Chattopadhyay K (2006) Microstructure development during dissimilar welding: case of laser welding of Ti with Ni involving intermetallic phase formation. J Mater Sci 41(3):643–652. doi:10.1007/s10853-006-6480-4

Chen HC, Pinkerton AJ, Li L (2011) Fibre laser welding of dissimilar alloys of Ti-6Al-4V and Inconel 718 for aerospace applications. Int J Adv Manuf Tech 52(9–12):977–987. doi:10.1007/s00170-010-2791-3

Manikandan P, Hokamoto K, Deribas AA, Raghukandan K, Tomoshige R (2006) Explosive welding of titanium/stainless steel by controlling energetic conditions. Mater Trans 47(8):2049–2055. doi:10.2320/matertrans.47.2049

Gao M, Mei SW, Wang ZM, Li XY, Zeng XY (2012) Characterisation of laser welded dissimilar Ti/steel joint using Mg interlayer. Sci Technol Weld Joi 17(4):269–276. doi:10.1179/1362171812Y.0000000002

Mitelea I, Groza C, Craciunescu CM (2014) Pulsed laser processing of dissimilar Ti-6Al-4V and X5CrNi18-10 joints. Mater Manuf Process 29(8):975–979. doi:10.1080/10426914.2013.822978

Maliutina IN, Stepanova NV, Cherkov AG, Chuchkova LV (2015) Welding of dissimilar materials with interlayers employment containing copper and tantalum. Obrabotka metallov (tehnologiya, oborudovanie, instrumenty) 4(69):61–71

Tomashchuk I, Grevey D, Sallamand P (2015) Dissimilar laser welding of AISI 316L stainless steel to Ti6-Al4-6V alloy via pure vanadium interlayer. Mat Sci Eng-A 622:37–45. doi:10.1016/j.msea.2014.10.084

Cherepanov AN, Mali VI, Maliutina IN, Orishich AM, Malikov AG, Drozdov VO (2016) Laser welding of stainless steel to titanium using explosively welded composite inserts. Int J Adv Manuf Tech 90:3037–3043. doi:10.1007/s00170-016-9657-2

Cherepanov AN, Orishich AM, Mali VI (2014) Laser welding of stainless steel with a titanium alloy with the use of a multilayer insert obtained in an explosion. Combust Explosion Shock Waves 50(4):483–487. doi:10.1134/S0010508214040182

Elmer JW, Palmer TA, Brasher D, Butler D, Riddle R (2005) Development of an explosive bonding process for producing high strength bonds between niobium and 6061-T651 aluminum. Weld J (Miami, Fla):1–44

Li HM, Sun DQ, Cai XL, Dong P, Wang WQ (2012) Laser welding of TiNi shape memory alloy and stainless steel using Ni interlayer. Mater Design 39:285–293. doi:10.1016/j.matdes.2012.02.031

Ng CH, Mok ESH, Man HC (2015) Effect of Ta interlayer on laser welding of NiTi to AISI 316L stainless steel. J Mater Process Tech 226:69–77. doi:10.1016/j.jmatprotec.2015.06.039

Shojaei Zoeram A, Akbari Mousavi SAA (2014) Effect of interlayer thickness on microstructure and mechanical properties of as welded Ti6Al4V/Cu/NiTi joints. Mater Lett 133:5–8. doi:10.1016/j.matlet.2014.06.141

Liu F, Ren D, Liu L (2013) Effect of Al foils interlayer on microstructures and mechanical properties of Mg-Al butt joints welded by gas tungsten arc welding filling with Zn filler metal. Mater Design 46:419–425. doi:10.1016/j.matdes.2012.10.012

Han JH, Ahn JP, Shin MC (2003) Effect of interlayer thickness on shear deformation behavior of AA5083 aluminum alloy/SS41 steel plates manufactured by explosive welding. J Mater Sci 38(1):13–18. doi:10.1023/A:1021197328946

Gurevich L, Trykov Y, Pronichev D, Trunov M (2014) Investigation on the contact hardening of Al/steel laminated composites with soft interlayers. WSEAS Trans Appl Theor Mech 9(1):275–281

Manikandan P, Hokamoto K, Fujita M, Raghukandan K, Tomoshige R (2008) Control of energetic conditions by employing interlayer of different thickness for explosive welding of titanium/304 stainless steel. J Mater Process Tech 195(1–3):232–240. doi:10.1016/j.jmatprotec.2007.05.002

Zakipour S, Samavatian M, Halvaee A, Amadeh A, Khodabandeh A (2015) The effect of interlayer thickness on liquid state diffusion bonding behavior of dissimilar stainless steel 316/Ti-6Al-4V system. Mater Lett 142:168–171. doi:10.1016/j.matlet.2014.11.158

Bazarnik P, Adamczyk-Cieślak B, Gałka A, Płonka B, Snieżek L, Cantoni M, Lewandowska M (2016) Mechanical and microstructural characteristics of Ti6Al4V/AA2519 and Ti6Al4V/AA1050/AA2519 laminates manufactured by explosive welding. Mater Des 111:146–157. doi:10.1016/j.matdes.2016.08.088

Hokamoto K, Izuma T, Fujita M (1993) New explosive welding technique to weld. Metall Trans A 24(10):2289–2297. doi:10.1007/BF02648602

Saravanan S, Raghukandan K, Hokamoto K (2016) Improved microstructure and mechanical properties of dissimilar explosive cladding by means of interlayer technique. Arch Civ Mech Eng 16(4):563–568. doi:10.1016/j.acme.2016.03.009

Saravanan S, Raghukandan K (2013) Influence of interlayer in explosive cladding of dissimilar metals. Mater Manuf Process 28(5):589–594. doi:10.1080/10426914.2012.736665

ISO 6892–1:2016 Metallic materials. Tensile testing. Part 1: method of test at room temperature (2016). International Organization for Standardization

ISO 5173:2009. Destructive tests on welds in metallic materials. Bend tests (2009). International Organization for Standardization

Crossland B (1982) Explosive welding of metals and its application. Clarendon press, Oxford

Zacharenko ID (1990) Svarka metallov vzrivom (in Russian). Nauka i technika, Minsk

Kiselev SP, Mali VI (2012) Numerical and experimental modeling of jet formation during a high-velocity oblique impact of metal plates. Combust Explosion Shock Waves 48(2):214–225. doi:10.1134/S0010508212020116

Murr LE, Pizaña C (2007) Dynamic recrystallization: the dynamic deformation regime. Metall Mater Trans A 38(11):2611–2628. doi:10.1007/s11661-007-9185-7

Bataev IA, Ogneva TS, Bataev AA, Mali VI, Esikov MA, Lazurenko DV, Guo Y, Jorge Junior AM (2015) Explosively welded multilayer Ni-Al composites. Mater Design 88:1082–1087. doi:10.1016/j.matdes.2015.09.103

Paul H, Morgiel J, Baudin T, Brisset F, Prazmowski M, Miszczyk M (2014) Characterization of explosive weld joints by TEM and SEM/EBSD. Arch Metall Mater 59(3):1129–1136. doi:10.2478/amm-2014-0197

Maliutina IN, Mali VI, Bataev IA, Bataev AA, Esikov MA, Smirnov AI, Skorokhod KA (2013, 2013) Structure and microhardness of Cu-Ta joints produced by explosive welding. Sci World J. doi:10.1155/2013/256758

Zareie Rajani HR, Akbari Mousavi SAA (2012) The effect of explosive welding parameters on metallurgical and mechanical interfacial features of Inconel 625/plain carbon steel bimetal plate. Mat Sci Eng-A 556:454–464. doi:10.1016/j.msea.2012.07.012

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mali, V.I., Bataev, A.A., Maliutina, I.N. et al. Microstructure and mechanical properties of Ti/Ta/Cu/Ni alloy laminate composite materials produced by explosive welding. Int J Adv Manuf Technol 93, 4285–4294 (2017). https://doi.org/10.1007/s00170-017-0887-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0887-8