Abstract

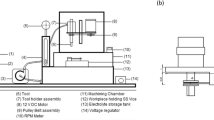

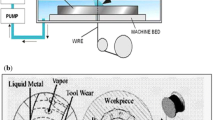

Nickel-based superalloy, Inconel 718, owing to its superior high-temperature strength, excellent fatigue, and corrosion resistance, has been widely used in the aerospace industry. However, there are inherent problems associated with the conventional machining of Inconel 718 superalloy. Therefore, in this work, investigation on machining of Inconel 718 using a hybrid machining process called abrasive mixed surface electro discharge diamond grinding (AMSEDDG) has been presented. In AMSEDDG, abrasive particles are mixed in a dielectric fluid and surface electric discharge diamond grinding (SEDDG) is performed on the workpiece. Preliminary comparative experimentation for AMSEDDG of Inconel 718 resulted in better performance in terms of material removal rate (MRR) and average surface roughness, compared to the performance of electro discharge machining, electro discharge grinding, and SEDDG. The response surface methodology approach has been used for performing and analyzing the experiments to explain the influences of four control factors, including the wheel speed, abrasive concentration, current, and pulse on time, on the performance measures of MRR and average surface roughness. The models established were found to be trustworthy representatives of the experimental results with prediction errors less than ±5%. The results represent that the addition of abrasives in dielectric has a significant effect on both performance measures. The desirability function approach for optimizing the process performance resulted in MRR of 14.45 mm3/min and average surface roughness of 2.621 μm for optimum settings of control factors, viz., wheel speed of 1355 RPM, abrasive concentration of 4 g/L, current of 6 A, and pulse on time of 22 μs.

Similar content being viewed by others

References

Aggarwal V, Khangura SS, Garg RK (2015) Parametric modeling and optimization for wire electrical discharge machining of Inconel 718 using response surface methodology. Int J Adv Manuf Technol 79(1–4):31–47. doi:10.1007/s00170-015-6797-8

Tian X, Zhao J, Zhao J, Gong Z, Dong Y (2013) Effect of cutting speed on cutting forces and wear mechanisms in high-speed face milling of Inconel 718 with Sialon ceramic tools. Int J Adv Manuf Technol 69(9–12):2669–2678. doi:10.1007/s00170-013-5206-4

Fang N, Pai PS, Mosquea S (2010) Effect of tool edge wear on the cutting forces and vibrations in high-speed finish machining of Inconel 718: an experimental study and wavelet transform analysis. Int J Adv Manuf Technol 52(1–4):65–77. doi:10.1007/s00170-010-2703-6

Rajurkar KP, Sundaram MM, Malshe AP (2013) Review of electrochemical and electrodischarge machining. Procedia CIRP 6:13–26. doi:10.1016/j.procir.2013.03.002

Shih HR, Shu KM (2007) A study of electrical discharge grinding using a rotary disk electrode. Int J Adv Manuf Technol 38(1–2):59–67. doi:10.1007/s00170-007-1068-y

Koshy P, Jain VK, Lal GK (1993) Experimental investigations into electrical discharge machining with a rotating disk electrode. Precis Eng 15(1):6–15. doi:10.1016/0141-6359(93)90273-d

Koshy P, Jain VK, Lal GK (1996) Mechanism of material removal in electrical discharge diamond grinding. Int J Mach Tool Manu 36(10):1173–1185

Unune DR, Mali HS (2014) Current status and applications of hybrid micro-machining processes: a review. Proc IMechE Part B: J Eng Manuf. doi:10.1177/0954405414546141

Kozak J (2002) Abrasive electro discharge grinding (AEDG) of advanced materials. Arch Civil Mech Eng 2:83–101

Yadav SKS, Yadava V, Narayana VL (2008) Experimental study and parameter design of electro-discharge diamond grinding. Int J Adv Manuf Tech 36(1–2):34–42

Singh GK, Yadava V, Kumar R (2010) Multiresponse optimization of electro-discharge diamond face grinding process using robust design of experiments. Mater Manuf Process 25(8):851–856

Singh GK, Yadava V, Kumar R (2010) Diamond face grinding of WC-Co composite with spark assistance: experimental study and parameter optimization. Int J Precis Eng Man 11(4):509–518

Singh GK, Yadava V, Kumar R (2012) Robust parameter design and multi-objective optimisation of electro-discharge diamond face grinding of HSS. Int J Mach Mach Mater 11(1):1. doi:10.1504/ijmmm.2012.044919

Agrawal SS, Yadava V (2013) Modeling and prediction of material removal rate and surface roughness in surface-electrical discharge diamond grinding process of metal matrix composites. Mater Manuf Process 28(4):381–389

Kumar H, Choudhary R, Singh S (2014) Experimental and morphological investigations into electrical discharge surface grinding (EDSG) of 6061Al/Al2O3p 10% composite by composite tool electrode. J Mater Eng Perfor 23(4):1489–1497. doi:10.1007/s11665-014-0899-6

Mali HS, Unune DR, Tiwari S Modelling and prediction of material removal rate in electrical discharge diamond surface grinding process of Inconel-718. In: Proceedings of 5th AIMTDR 2014, IIT Guwahati, India, 2014. pp 822:821–822:828

Unune DR, Mali HS (2015) Artificial neural network–based and response surface methodology–based predictive models for material removal rate and surface roughness during electro-discharge diamond grinding of Inconel 718. Proc IMechE Part B: J Eng Manuf 230(11):2082–2091. doi:10.1177/0954405415619347

Klocke F, Lung D, Antonoglou G, Thomaidis D (2004) The effects of powder suspended dielectrics on the thermal influenced zone by electrodischarge machining with small discharge energies. J Mater Process Tech 149(1–3):191–197. doi:10.1016/j.jmatprotec.2003.10.036

Kansal HK, Singh S, Kumar P (2005) Parametric optimization of powder mixed electrical discharge machining by response surface methodology. J Mater Process Tech 169(3):427–436. doi:10.1016/j.jmatprotec.2005.03.028

Kumar A, Maheshwari S, Sharma C, Beri N (2010) A study of multiobjective parametric optimization of silicon abrasive mixed electrical discharge machining of tool steel. Mater Manuf Process 25(10):1041–1047. doi:10.1080/10426910903447303

Kumar A, Maheshwari S, Sharma C, Beri N (2011) Analysis of machining characteristics in additive mixed electric discharge machining of nickel-based super alloy Inconel 718. Mater Manuf Process 26(8):1011–1018

Garg RK, Singh KK, Sachdeva A, Sharma VS, Ojha K, Singh S (2010) Review of research work in sinking EDM and WEDM on metal matrix composite materials. Int J Adv Manuf Technol 50(5–8):611–624. doi:10.1007/s00170-010-2534-5

Kumar S, Batra U (2012) Surface modification of die steel materials by EDM method using tungsten powder-mixed dielectric. J Manuf Process 14(1):35–40. doi:10.1016/j.jmapro.2011.09.002

Modi M, Agarwal G (2013) Powder-mixed electro-discharge diamond surface grinding process: modelling, comparative analysis and multi-output optimisation using weighted principal components analysis. Strojniški vestnik – J Mech Eng 59(12):735–747. doi:10.5545/sv-jme.2013.1146

Unune DR, Singh VP, Mali HS (2015) Experimental investigations of abrasive mixed electro discharge diamond grinding of Nimonic 80A. Mater Manuf Process 31:1718–1723. doi:10.1080/10426914.2015.1090598

Youssefi S, Emam-Djomeh Z, Mousavi SM (2009) Comparison of artificial neural network (ANN) and response surface methodology (RSM) in the prediction of quality parameters of spray-dried pomegranate juice. Dry Technol 27(7–8):910–917. doi:10.1080/07373930902988247

Montgomery DC (2009) Design and analysis of experiments. Wiley, New York

Yadav RN, Yadava V (2013) Influence of input parameters on machining performances of slotted-electrical discharge abrasive grinding of Al/SiC/Gr metal matrix composite. Mater Manuf Process 28(12):1361–1369

Yadav RN, Yadava V (2013) Experimental study of erosion and abrasion based hybrid machining of hybrid metal matrix composite. Int J Precis Eng Man 14(8):1293–1299

El-Taweel TA, Gouda SA (2010) Performance analysis of wire electrochemical turning process—RSM approach. Int J Adv Manuf Technol 53(1–4):181–190. doi:10.1007/s00170-010-2809-x

Kumar A, Kumar V, Kumar J (2013) Multi-response optimization of process parameters based on response surface methodology for pure titanium using WEDM process. Int J Adv Manuf Technol 68(9–12):2645–2668. doi:10.1007/s00170-013-4861-9

Peças P, Henriques E (2008) Electrical discharge machining using simple and powder mixed dielectric: the effect of the electrode area in the surface roughness and topography. J Mater Process Technol 200:250–258. doi:10.1016/j.jmatprotec.2007.09.051

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Unune, D.R., Mali, H.S. Parametric modeling and optimization for abrasive mixed surface electro discharge diamond grinding of Inconel 718 using response surface methodology. Int J Adv Manuf Technol 93, 3859–3872 (2017). https://doi.org/10.1007/s00170-017-0806-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0806-z