Abstract

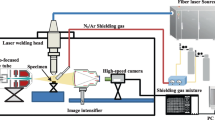

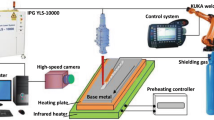

The porosity produced in the 304 stainless steel laser welds was investigated. The laser welding process was conducted at a laser power of 10 kW. Different welding speeds and shielding gases were used. The porosity in the welds was characterized. The welding processes were observed using a high-speed video camera. The mechanism of the elimination of the porosity was revealed. The suppression of the porosity was made in N2 rather than Ar or He shielding gases. The porosity was mainly produced at the root and most of the porosity was less than 0.02 mm3. No significant differences of the metallic plume, liquid melt pool, and laser keyhole were found when Ar or N2 shielding gas was employed. The solubility of N2 in the liquid melt pool contributed to the reduction or elimination of the porosity in the 304-L laser welds.

Similar content being viewed by others

References

Zhang M, Chen G, Zhou Y, Liao S (2014) Optimization of deep penetration laser welding of thick stainless steel with a 10 kW fiber laser. Mater Des 53:568–576

Shen X, Li L, Guo W, Teng W, He W (2016) Comparison of processing window and porosity distribution in laser welding of 10mm thick 30CrMnSiA ultrahigh strength between flat (1G) and horizontal (2G) positions. J Laser Appl 28:022418/1–022418/9

Atabaki M, Yazdian N, Ma J, Kovacevic R (2016) High power laser welding of thick steel plates in a horizontal butt joint configuration. Opt Laser Technol 83:1–12

Beretta S, Previtali B (2009) Estimate of maximum pore size in keyhole laser welding of carbon steel. Sci Technol Weld Join 14:106–116

Tsukamoto S (2011) High speed imaging technique part 2-high speed imaging of power beam welding phenomena. Sci Technol Weld Join 16:44–55

Ola O, Doern F (2015) Keyhole-induced porosity in laser-arc hybrid welded aluminum. Int J Adv Manuf Technol 80:3–10

Matsunawa A (2001) Problems and solutions in deep penetration laser welding. Sci Technol Weld Join 6:351–354

Kawahito Y, Mizutani M, Katayama S (2009) High quality welding of stainless steel with 10 kW high power fiber laser. Sci Technol Weld Join 14:288–294

Zhao H, Niu W, Zhang B, Lei Y, Kodama M, Ishide T (2011) Modeling of keyhole dynamics and porosity formation considering the adaptive keyhole shape and three-phase coupling during deep-penetration laser welding. J Phys D Appl Phys 44:485302/1–485302/13

Kuo T, Jeng S (2005) Porosity reduction in Nd-YAG laser welding of stainless steel and inconel alloy by using a pulsed wave. J Phys D Appl Phys 38:722–728

Harooni M, Carlson B, Strohmeier B, Kovacevic R (2014) Pore formation mechanism and its mitigation in laser welding of AZ31B magnesium alloy in lap joint configuration. Mater Des 58:265–276

Kamimuki K, Inoue T, Yasuda K, Muro M, Nakabayashi T, Matsunawa A (2002) Prevention of welding defect by side gas flow and its monitoring method in continuous wave Nd: YAG laser welding. J. Laser Appl. 14:136–145

Meng W, Li Z, Huang J, Wu Y, Katayama S (2014) The influence of various factors on the geometric profile of laser lap welded T-joints. Int J Adv Manuf Technol 74:1625–1636

Li K, Lu F, Cui H, Li X, Tang X, Li Z (2015) Investigation on the effects of shielding gas on porosity in fiber laser welding of T-joint steels. Int J Adv Manuf Technol 77:1881–1888

Sun J, Feng K, Zhang K, Guo B, Jiang E, Nie P, Li Z (2017) Fiber laser welding of thick AISI 304 plate in a horizontal (2G) butt joint configuration. Mater Des 118:53–65

Wei P, Chao T (2015) The effects of entrainment on pore shape in keyhole mode welding. J Heat Trans 137:082102/1–082102/9

Tucker J, Nolan T, Martin A, Young G (2012) Effect of travel speed and beam focus on porosity in alloy 690 laser welds. J Miner Met Mater Soc (JOM) 64:1409–1417

Katayama S, Mizutani M, Matsunawa A (2003) Development of porosity prevention procedures during laser welding. Proc SPIE 4331:281–288

Elmer J, Vaja J, Carlton H, Pong R (2015) The effect of Ar and N2 shielding gas on laser weld porosity in steel, stainless steels, and nickel. Weld J 94:313–325

Pang S, Chen X, Shao X, Gong S, Xiao J (2016) Dynamics of vapor plume in transient keyhole during laser welding of stainless steel: local evaporation, plume swing and gas entrapment into porosity. Opt Laser Technol 82:28–40

Li Z, Mukai K, Zeze M, Mills K (2005) Determination of the surface tension of liquid stainless steel. J Mater Sci 40:2191–2195

Dischino A, Kenny J, Mecozzi M, Barteri M (2000) Development of high nitrogen, low nickel, 18%Cr austenitic stainless steels. J Mater Sci 35:43803–43808

Lai R, Cai Y, Wu Y, Li F, Hua X (2016) Influence of absorbed nitrogen on microstructure and corrosion resistance of 2205 duplex stainless steel joint processed by fiber laser welding. J Mater Process Tech 231:397–405

Keskitalo M, Mantyjarvi K, Sundqvist J, Powell J, Kaplan A (2016) Laser welding of duplex stainless steel with nitrogen as shielding gas. J Mater Process Tech 216:381–384

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Sun, J., Nie, P., Lu, F. et al. The characteristics and reduction of porosity in high-power laser welds of thick AISI 304 plate. Int J Adv Manuf Technol 93, 3517–3530 (2017). https://doi.org/10.1007/s00170-017-0734-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0734-y