Abstract

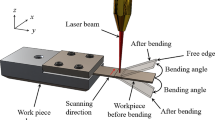

Laser bending is an innovative technology that uses a laser beam to bend metal sheets and/or components. It offers advantages such as lack of equipment, high flexibility, adaptability to different materials (including metal foams), and possibility of automation. Actually, the angle can be measured only after the laser-bending process. The acoustic emission (AE) technique offers a great potential for the “on-time” evaluation of the bending angle: this technique is based on the detection of high-frequency acoustic signals emitted during the phenomena evolution deriving from the deformation and/or fracture of a component/structure. This paper presents an initial approach to understand the relationship between bending angle and the characteristics of the AE signals generated during the laser-material interaction. In this work, a diode laser is used to bend an AISI 304 stainless steel sheet: the laser parameters used and the bending angle obtained were correlated with each other. A useful dependence between laser bending and AE parameters was found.

Similar content being viewed by others

References

S. Edwards (2004) A study into the 2D and 3D laser forming of metallic components. PhD Thesis, Laser Group, Department of Engineering, the University of Liverpool, UK

Y. Namba (1985) Laser forming in space. In: Proceedings of the International Conference on Lasers. Las Vegas 403–407

Y. Namba (1987) Laser forming of metals and alloys. In: Proceedings of the LAMP, Osaka 601–606

Walczyk F, Vittal S (2000) Bending of titanium sheet using laser forming. J Manuf Process 2/4:258–269. doi:10.1016/S1526-6125(00)70027-2

Shen H, Yao Z, Hu J (2009) Numerical analysis of metal/ceramic bilayer materials systems in laser forming. Comput Mater Sci 45:439–442. doi:10.1016/j.commatsci.2008.11.009

Quadrini F, Guglielmotti A, Squeo EA, Tagliaferri V (2010) Laser forming of open-cell aluminum foams. J Mater Process Technol 210/11:1517–1522. doi:10.1016/j.jmatprotec.2010.04.010

Vollertsen F (1994) An analytical model for laser bending. Lasers in Engineering 2:261–276

Wu D, Zhang Q, Ma G, Guo Y, Guo D (2010) Laser bending of brittle materials. Opt Lasers Eng 48/4:405–410. doi:10.1016/j.optlaseng.2009.09.009

Geiger M, Vollertsen F (1993) The mechanism of laser forming. CIRP Ann 42:301–304. doi:10.1016/S0007-8506(07)62448-2

C.L. Yau, K.C. Chan, W.B. Lee (1997) A new analytical model for laser bending. In: Laser Assisted Net Shape Engineering 2, Proceedings of the LANE 2:357–366

Z. Mucha, J. Hoffman, W. Kalita, S. Mucha (1997) Laser forming of thick free plates. In: Laser Assisted Net Shape Engineering 2, Proceedings of the LANE 383–392

Kyrsanidi AK, Kermanidis TB, Pantelakis SG (2000) Analytical model for the prediction of distortions caused by the laser forming process. J Mater Process Technol 104:94–102. doi:10.1016/S0924-0136(00)00520-3

Cheng PJ, Lin SC (2001) Analytical model to estimate angle formed by laser. J Mater Process Technol 108:314–319. doi:10.1016/S0924-0136(00)00858-X

Yu G, Anderson RJ, Maekawa T, Patrikalakis NM (2001) Efficient simulation of shell forming by line heating. Int J Mech Sci 43/10:2349–2370. doi:10.1016/S0020-7403(01)00037-6

Vollertsen F, Komel I, Kals R (1995) The laser bending of steel foils for microparts by the buckling mechanism—a model. Model Simul Mater Sci Eng 3/1:107–119

Shen H, Shi YJ, Yao ZQ, Hu J (2006) An analytical model for estimating deformation in laser forming. Comput Mater Sci 37:593–598. doi:10.1016/j.commatsci.2005.12.030

Shi YJ, Liu YC, Yao ZQ, Shen H (2008) A study on bending direction of sheet metal in laser forming. J Appl Phys 103:Art. n053101. doi:10.1063/1.2887995

J. Kraus (1997) Basic processes in laser bending of extrusions using the upsetting mechanism. In: Laser Assisted Net Shape Engineering 2, Proceedings of the LANE 2: 431–438

J. Magee (1999) Laser forming of aerospace alloys. Ph.D. Thesis, University of Liverpool

S.P. Edwardson (2004) A study into the 2D and 3D laser forming of metallic components. Ph.D. Thesis, University of Liverpool

Cheng PJ, Lin SC (2000) Using neural networks to predict bending angle of sheet metal formed by laser. Int J Mach Tools Manuf 40:1185–1197. doi:10.1016/S0890-6955(99)00111-X

Casalino G, Ludovico AD (2002) Parameter selection by an artificial neural network for a laser bending process. Proc Inst Mech Eng Part B-J Eng 216/11:1517–1520. doi:10.1243/095440502320783350

Kyrsanidi ANK, Kermanidis THB, Pantelakis SPG (2000) An analytical model for the prediction of distortions caused by the laser forming process. J Mater Process Technol 104:94–102. doi:10.1016/S0924-0136(00)00520-3

Marya M, Edwards GR (2002) An analytical model for the optimisation of the laser bending of titanium Ti-6Al-2Sn-4Zr-2Mo. J Mater Process Technol 124:337–344. doi:10.1016/S0924-0136(02)00223-6

Liu FR, Chan KC, Tang CY (2005) Theoretical analysis of deformation behaviour of aluminium matrix composites in laser forming. Mater Sci Eng A-Struct Mater 396:172–180. doi:10.1016/j.msea.2005.01.036

Shichun W, Jinsong Z (2001) An experimental study of laser bending for sheet metals. J of Mat Proc Tech 110:160–163. doi:10.1016/S0924-0136(00)00860-8

Duflou JR, Callebaut B, Verbert J, De Baerdemaeker H (2007) Laser assisted incremental forming: formability and accuracy improvement. CIRP Ann-Manuf Technol 56/1:273–276. doi:10.1016/j.cirp.2007.05.063

Geiger M, Vollertsen F, Deinzer G (1993) Flexible straightening of car body shells by laser forming. International Congress and Exposition, Dearborn, pp 1–5 Paper 930279. doi:10.4271/930279

R. Kant, S.N. Joshi, U.S. Dixit (2015) Research issues in the laser sheet bending process. In: Materials Forming and Machining: Research and Development. Woodhead Publishing pp. 73–97, Cambridge, ISBN: 978-0857094834, doi:10.1016/B978-0-85709-483-4.00004-1.

Gopal Chandra Jha, Nath AK, Roy SK (2008) Study of edge effect and multi-curvature in laser bending of AISI 304 stainless steel. J Mater Process Technol 197:434–438. doi:10.1016/j.jmatprotec.2007.06.040

Hoseinpour Gollo M, Mahdavian SM, Moslemi Naeini H (2011) Statistical analysis of parameter effects on bending angle in laser forming process by pulsed Nd:YAG laser. Opt Laser Technol 43:475–482. doi:10.1016/j.optlastec.2010.07.004

V. Paunoiu, E.A. Squeo, F. Quadrini, C. Gheorghies, D. Nicoara (2008) Laser bending of stainless steel sheet metals. Int J Mater Form (1):1371–1374, doi: 10.1007/s12289-008-0119-8.

Shen H, Hu J, Yao Z (2010) Analysis and control of edge effects in laser bending. Opt Lasers Eng 48:305–315. doi:10.1016/j.optlaseng.2009.11.005

M. Hoseinpour Gollo, H. Moslemi Naeini, G.H. Liaghat, M.J. Torkamany, S. Jelvani, V. Panahizade (2008) An experimental study of sheet metal bending by pulsed Nd:YAG laser with DOE method. Int J Mater Form (Supp. 1):137–140, doi: 10.1007/s12289-008-0 010-7.

Lambiase F, Di Ilio A, Paoletti A (2016) Productivity in multi-pass laser forming of thin AISI 304 stainless steel sheets. Int J Adv Manuf Technol 86:259–268. doi:10.1007/s00170-015-8150-7

Lambiase F, Di Ilio A, Paoletti A (2013) An experimental investigation on passive water cooling in laser forming process. Int J Adv Manuf Technol 64/5-8:829–840. doi:10.1007/s00170-012-4072-9

Lambiase F, Di Ilio A (2013) A closed-form solution for thermal and deformation fields in laser bending process of different materials. Int J Adv Manuf Technol 69:849–861. doi:10.1007/s00170-013-5084-9

Lambiase F, Di Ilio A, Paoletti A (2015) Optimization of multi-pass laser bending by means of soft computing techniques. Procedia CIRP 33:502–507. doi:10.1016/j.procir.2015.06.063

AMSY5 user’s manual. Vallen System, http://www.vallen.de/downloads/, Last Access 30 03 2017.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Genna, S., Papa, I. & Leone, C. A preliminary study on the characterization of laser-bending process of AISI 304 steel sheets by acoustic emission technique. Int J Adv Manuf Technol 92, 4111–4119 (2017). https://doi.org/10.1007/s00170-017-0483-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0483-y