Abstract

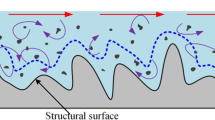

To resolve the problems of uniformity and efficiency of soft abrasive flow (SAF) processing for complex titanium alloy surfaces, a gas compensation-based abrasive flow (GCAF) processing method is proposed. By the constrained modules, an enclosed flow passage covering the titanium alloy surface is built up, in which the gas phase is injected to enhance the turbulence intensity of abrasive flow. Taking the constrained flow passage as the objective, a three-phase fluid mechanic model for GCAF is set up based on the realizable k-ε model and the mixture model. The profiles of velocity and dynamical pressure of abrasive flow field in the constrained flow passage are obtained, and the turbulence variation regulars caused by gas compensation are revealed. Numerical results show that the proposed method can strengthen the turbulence intensity of abrasive and improve the distribution uniformity of dynamical pressure. A GCAF processing experimental platform is developed, and the experiments are performed. The results prove that the proposed method can obtain better processing efficiency and uniformity, the average surface roughness is less than Ra 0.3, and the surface topograph of micro-peak and micro-valley can reach less than 50 and 10 μm, respectively.

Similar content being viewed by others

References

Zeng Xi, Li Jue-hui, Ji Shi-ming, Pan Ye, Hang Wei, Chen Guo-da (2017) Research on machining characteristic of double-layer elastomer in pneumatic wheel method. Int J Adv Manuf Technol (Article in Press, DOI: 10.1007/s00170-017-0226-0)

Wang ZW, Taskin AA, Frolich T, Braden M, Ando Y (2016) Superconductivity in Ti0.6Bi2Te3 derived from a topological insulator. Chem Mat 28(3):779–784

Pal VK, Choudhury SK (2008) Fabrication of texturing tool to produce array of square holes for EDM by abrasive water jet machining. Int J Adv Manuf Technol 85(9–12):2061–2071

Li C, Ji SM, Tan DP (2012) Study on machinability and the wall region of solid-liquid two phase softness abrasive flow. Int J Adv Manuf Technol 61(9–12):975–987

Wang CT, Jin ZM (2012) Wear analysis of artificial hip joint and reasoning of clinical failure diagnosis. J Med Biomech 27(4):361–368

He Y, Wu Y, Fu JZ, Gao Q, Qiu JJ (2016) Developments of 3D printing microfluidics and applications in chemistry and biology: a review. Electroanalysis 28(8):1658–1678

Zhao YQ, Liu HJ, Yang TF, Lin Z, Hu YY (2016) Study of temperature and material flow during friction spot welding of 7B04-T74 aluminum alloy. Int J Adv Manuf Technol 83(9–12):1467–1475

Lambiase F, Paoletti A, Di Ilio A (2016) Mechanical behaviour of friction stir spot welds of polycarbonate sheets. Int J Adv Manuf Technol 80(1–4):301–314

Zeng X, Ji SM, Jin MS, Tan DP, Li JH, Zeng WT (2014) Investigation on machining characteristic of pneumatic wheel based on softness consolidation abrasives. Int J Precis Eng Manuf 15(10):2031–2039

Ji SM, Xiao FQ, Tan DP (2010) Analytical method for softness abrasive flow field based on discrete phase model. Sci China - Technol Sci 53(10):2867–2877

Ji SM, Tang B, Tan DP, Gong B, Yuan QL, Pan Y (2010) Structured surface softness abrasive flow precision finish machining and its abrasive flow dynamic numerical analysis. Chinese J Mech Eng 46(15):178–184

Tan DP, Ji SM, Li PY, Pan XH (2010) Development of vibration style ladle slag detection method and the key technologies. Sci China - Technol Sci 53(9):2378–2387

Ji SM, Xiao FQ, Tan DP (2010) A new ultraprecision machining method with softness abrasive flow based on discrete phase model. Adv Mater Res 97-101:3055–3059

Yuan QL, Ji SM, Tan DP, Zhang L (2011) Analytical method for softness abrasive flow field based on low Reynolds k-epsilon model. Adv Mater Res 188:230–235

Ji SM, Zhong JQ, Tan DP, Chi YW (2012) Research of distribution and dynamic characteristic of particle group in the structural flow passage. Key Eng Mater 499:271–276

Zeng X, Ji SM, Jin MS, Tan DP, Ge JQ (2015) Research on dynamic characteristic of softness consolidation abrasives in machining process. Int J Adv Manuf Technol 82(5–8):1115–1125

Ji SM, Weng XX, Tan DP (2012) Analytical method of softness abrasive two-phase flow field based on 2D model of LSM. Acta Phys Sin 61(1):010205

Ji SM, Qiu Y, Cai YJ, Tan DP (2014) Research on mechanism of ultrasound enhancing and the experiment based on softness abrasive flow. Chinese J Mech Eng 50(7):84–93

Zhang L, Deng B, Xie Y, Zhang R, Ji SM, Wen DH (2015) Curved surface turbulence precision machining method for artificial joint complex of titanium alloy. Mater Res Innov 19(S8):55–59

Tan DP, Ji SM, Fu YZ (2016) An improved soft abrasive flow finishing method based on fluid collision theory. Int J Adv Manuf Technol 85(5–8):1261–1274

Ji SM, Huang XH, Tan DP, Tan YF (2016) Gas-liquid-solid abrasive flow polishing and its process parameter optimization. Opt Precis Eng 24(4):855–864

Tan DP, Zhang LB (2014) A WP-based nonlinear vibration sensing method for invisible liquid steel slag detection. Sensor Actuat B - Chem 202:1257–1269

Tan Da-peng, Ni Ye-sha, Zhang Li-bin (2016) Two-phase sink vortex suction mechanism and penetration dynamic characteristics in ladle teeming process. J Iron Steel Res Int (Article in Press)

Chen JL, Xu F, Tan DP, Shen Z, Zhang LB, Ai QL (2015) A control method for agricultural greenhouses heating based on computational fluid dynamics and energy prediction model. Appl Energ 141:106–118

Tan DP, Li PY, Ji YX, Wen DH, Li C (2013) SA-ANN-based slag carry-over detection method and the embedded WME platform. IEEE T Ind Electron 60(10):4702–4713

Tan DP, Li PY, Pan XH (2009) Application of improved HMM algorithm in slag detection system. J Iron Steel Res Int 16(1):1–6

Zeng X, Ji SM, Tan DP, Jin MS, Wen DH, Zhang L (2013) Softness consolidation abrasives material removal characteristic oriented to laser hardening surface. Int J Adv Manuf Technol 69(9–12):2323–2332

Tan DP, Ji SM, Jin MS (2013) Intelligent computer-aided instruction modeling and a method to optimize study strategies for parallel robot instruction. IEEE T Educ 56(3):268–273

Tan DP, Yang T, Zhao J, Ji SM (2016) Free sink vortex Ekman suction-extraction evolution mechanism. Acta Phys Sin 65(5):054701

Li C, Ji SM, Tan DP (2013) Multiple-loop digital control method for 400Hz inverter system based on phase feedback. IEEE T Power Electron 28(1):408–417

Tan DP, Li PY, Pan XH (2008) Intelligent industry monitoring network architecture UPnP based. Chinese J Electron 17(4):607–610

Tan Da-peng, Chen Shu-ting, Bao Guan-jun, Zhang Li-bin (2017) An embedded lightweight GUI component library and the ergonomics optimization method for industry process monitoring. Front Inform Technol Elect Eng (Article in Press, DOI: 10.1631/FITEE.1601660)

Castilla R, Gamez-Montero PJ, Ertürk N, Vernet A, Coussirat M, Codina E (2010) Numerical simulation of turbulent flow in the suction chamber of a gearpump using deforming mesh and mesh replacement. Int J Mech Sci 52(10):1334–1342

Gruber MC, Radl S, Khinast JG (2016) Effect of bubble-particle interaction models on flow predictions in three-phase bubble columns. Chem Eng Sci 146:226–243

Li Jun, Ji Shi-ming, Tan Da-peng (2017) Improved soft abrasive flow finishing method based on turbulent kinetic energy enhancing. Chinese J Mech Eng (Article in Press, DOI: 10.1007/s10033-017-0071-y)

Mei DQ, Wang H, Yao ZH, Li Y (2016) Numerical modeling and optimization of the segmented PbTe-BiTe-based thermoelectric leg. J Appl Phys 120(12):124503

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Wang, Js., Tan, Dp. et al. Gas compensation-based abrasive flow processing method for complex titanium alloy surfaces. Int J Adv Manuf Technol 92, 3385–3397 (2017). https://doi.org/10.1007/s00170-017-0400-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0400-4