Abstract

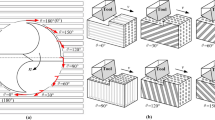

The current knowledge about composite material machining is inadequate for its optimum utilization in many applications owing to the complexity of the phenomena involved in the cutting area. The objective of this study is to investigate the cutting mechanisms during carbon/epoxy composite drilling. It has been found that fiber orientation relative to the cutting direction is a key factor affecting machining results. Orthogonal cutting has helped to understand phenomena involved in the cutting area. The most common mechanisms noted are shearing, bending, and fiber/matrix interface debonding. It has been also noticed that surface quality, temperature fields’ cartographies, and cutting forces change markedly with fiber orientation.

Similar content being viewed by others

References

Li N, Li Y, Zhou J, He Y, Hao X (2015) Drilling delamination and thermal damage of carbon nanotube/carbon fiber reinforced epoxy composites processed by microwave curing. Int J Mach Tool Manu 97:11–17

Gaugel S, Sripathy P, Haeger A, Meinhard D, Bernthaler T, Lissek F, Kaufeld M, Knoblauch V, Schneider G (2016) A comparative study on tool wear and laminate damage in drilling of carbonfiber reinforced polymers (CFRP). Compos Struct. doi:10.1016/j.compstruct.2016.08.004

Duraõ LMP, Tavares JMRS, de Albuquerque VHC, Gonçalves DJS (2013) Damage evaluation of drilled carbon/epoxy laminates based on area assessment methods. Compos Struct 96:576–583

Grilo TJ, Silva RMF, Davim JP (2013) Experimental delamination analyses of CFRPs using different drill geometries. Compos Part B-ENG 45:1344–1350

Turki Y, Habak M, Velasco R, Laurent JN, Vantomme P (2013) An experimental study of drilling parameters effect on composite carbon/epoxy damage. Key Eng Mat 554-557:2038–2046

Babu J, Philip J, Zacharia T, Davim J (2015) Delamination in composite materials: measurement, assessment and prediction. In: Davim JP. Machinability of fiber reinforced plastics, Berlin: De Gruyter: 139–162

Babu J, Sunny T, Paul N, Mohan K, Philip J, Davim J (2015) Assessment of delamination in composite materials: a review. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture

Persson E, Eriksson I, Zackrisson L (1997) Effects of hole machining defects on strength and fatigue life of composite laminates. Compos Part A-Appl S 28:141–151

Duraõ LMP, Gonçalves DJS, Tavares JMRS et al (2010) Drilling tool geometry evaluation for reinforced composite laminates. Compos Struct 92:1545–1550

Wang C, Cheng K, Rakowski R, Greenwood D, Wale J (2016) Comparative studies on the effect of pilot drillings with application to high-speed drilling of carbon fibre reinforced plastic (CFRP) composites. Int J Adv Manuf Tech. doi:10.1007/s00170-016-9268-y

Tsao CC (2008) Experimental study of drilling composite materials with step-core drill. Mater and design 29:1740–1744

Marques AT, Duraõ LMP, Magalhaes AG et al (2009) Delamination analysis of carbon fibre reinforced laminates: evaluation of a special step drill. Compos Sci and Technol 69:2376–2382

Zitoune R, Krishnaraj V, Almabouacif BS et al (2012) Influence of machining parameters and new nano-coated tool on drilling performance of CFRP/Aluminium sandwich. Compos Part B-ENG 43:1480–1488

Rahme P, Landon Y, Lachaud F, Piquet R, Lagarrigue P (2014) Drilling of thick composite material with a small-diameter twist drill. Int J Adv Manuf Tech. doi:10.1007/s00170-014-6374-6

Bonnet C (2010) Comprehensive study of cutting phenomena for titanium alloys Ti6Al4V and CFRP stacks drilling in dry condition (Compréhension des mécanismes de coupe lors du perçage à sec de l’empilage Ti6Al4V/Composite fibre de carbone). Dissertation, ENAM

Hocheng H, Dharan CKH (1990) Delamination during drilling in composite laminates. J Manuf Sci E 112(3):236–239

Lachaud F, Piquet R, Collombet F, Surcin L (2001) Drilling of composite structures. Compos Struct 52:511–516

Rahmé P, Landon Y, Lachaud F et al (2011) Analytical models of composite material drilling. Int J Adv Manuf Tech 52:609–617

Sedláèek J, Humár A (2008) Analysis of fracture mechanisms and surface quality in drilling of composite materials. Strength Mater+ 40(1):48–51

Seif MA, Khashaba UA, Rojas-Oviedo R (2007) Measuring delamination in carbon/epoxy composites using a shadow moiré laser based imaging technique. Compos Struct 79:113–118

Davim JP, Rubio JC, Abrao AM (2007) A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos Sci and Technol 67:1939–1945

Durão LMP, Magalhães AG, Tavares JMRS, Marques AT (2006) Analyzing objects in images for estimating the delamination influence on load carrying capacity of composite laminates. In: Proceedings of Composite Image. Coimbra, Portugal, Taylor & Francis, pp 169–174. ISBN: 9780415433495

Iliescu D, Gehin D, Iordanoff I et al (2010) A discrete element method for the simulation of CFRP cutting. Compos Sci and Technol 70:73–80

Lin SC, Chen IK (1996) Drilling carbon fiber-reinforced composite material at high speed. Wear 194:156–162

Brinksmeier E, Janssen R (2002) Drilling of multi-layer composite materials consisting of carbon fiber reinforced plastics (CFRP), titanium and aluminum alloys. CIRP Ann Manuf Technol 51(1):87–90

Merino-Pérez JL, Royer R, Merson E, Lockwood A, Ayvar-Soberanis S, Marshall MB (2016) Influence of workpiece constituents and cutting speed on the cutting forces developed in the conventional drilling of CFRP composites. Compos Struct 140:621–629

Bonnet C, Poulachon G, Rech J, Girard Y, Costes JP (2015) CFRP drilling: fundamental study of local feed force and consequences on hole exit damage. Int J Mach Tool Manu 94:57–64

Li MJ, Soo SL, Aspinwall DK, Pearson D, Leahy W (2014) Influence of lay-up configuration and feed rate on surface integrity when drilling carbon fibre reinforced plastic (CFRP) composites. Procedia CIRP 13. 2nd CIRP Conference on Surface Integrity (CSI): 399–404

Duraõ LMP, de Moura MFSF, Marques AT (2008) Numerical prediction of delamination onset in carbon/epoxy composites drilling. Eng Fract Mech 75(9):2767–2778

Hintze W, Hartmann D, Schütte C (2011) Occurrence and propagation of delamination during the machining of carbon fibre reinforced plastics (CFRPs)—an experimental study. Compos Sci and Technol 71:1719–1726

Ramirez C, Poulachon G, Rossi F, M’Saoubi R (2014) Tool wear monitoring and hole surface quality during CFRP drilling. 2nd CIRP Conference on Surface Integrity (CSI), Procedia CIRP: 163–168

Poulachon G, Outeiro J, Ramirez C, André V, Abrivard G (2016) Hole surface topography and tool wear in CFRP drilling. 3rd CIRP Conference on Surface Integrity (CIRP CSI) Procedia CIRP 45: 35–38

Gohorianu G (2008) Interaction between drilling defects and bearing behaviour of carbon/epoxy bolted joints (Interaction entre les défauts d’usinage et la tenue en matage d’assemblages boulonnes en carbone/epoxy). Dissertation, University of Toulouse

Krishnaraj V, Prabukarthi A, Ramanathan A et al (2012) Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos Part B-ENG 43:1791–1799

Arola D, Ramulu M, Wang DH (1996) Chip formation in orthogonal trimming of graphite/epoxy composite. Compos Part A-Appl S 27:121–133

Teti R, Machining of composite materials. University of Naples Federico II, Italy

Klocke F, Konig W, Rummenholler S, Wurtz C (1999) Milling of advanced composites, In Machining of ceramics and composites. Eds. Jahanmir S, Ramulu M, Koshy P, Dekker M. Inc.:249–265

Wang XM, Zhang LC (2003) An experimental investigation into the orthogonal cutting of unidirectional fibre reinforced plastics. Int J Mach Tool Manu 43:1015–1022

Calzada KA, Kapoor SG, De Vor RE et al (2012) Modeling and interpretation of fiber orientation-based failure mechanisms in machining of carbon fiber-reinforced polymer composites. J Manuf Process 14:141–149

Henerichs M, Voß R, Kuster F, Wegener K (2014) Machining of carbon fiber reinforced plastics: influence of tool geometry and fiber orientation on the machining forces. CIRP J Manu Sci and Tech. doi:10.1016/ j.cirpj.2014.11.002

Bhatnagar N, Ramakrishnan N, Naik NK, Komanduri R (1995) On the machining of fiber reinforced plastic (FRP) composite laminates. Int J Mach Tool Manu 35(5):701–716

Venu Gopala Rao G, Mahajan P, Bhatnagar N (2007) Micro-mechanical modeling of machining of FRP composites: cutting force analysis. Compos Sci and Technol 67:579–593

Wang DH, Ramulu M, Arola D (1995) Orthogonal cutting mechanisms of graphite/epoxy composite. Part I: unidirectional laminate. Int J Mach Tool Manu 35(12):1623–1638

Nayak D, Singh I, Bhatnagar N, Mahajan P (2005) Finite element analysis of effect of machining direction on fibre orientation of FRP composites. IE(I) Journal-PR 85:64–67

Santo L, Caprino G, De lorio I (1998) Cutting forces and cut quality in orthogonal cutting of unidirectional carbon fibre reinforced plastics. Integrated Design and Process Technology 3:282–287

Venu Gopala Rao G, Mahajan P, Bhatnagar N (2008) Three-dimensional macro-mechanical finite element model for machining of unidirectional-fiber reinforced polymer composites. Mater Sci and Eng 498A:142–149

Iliescu D (2008) Experimental and numerical approaches of machining of dry carbon/epoxy composites (Approches expérimentale et numérique de l'usinage à sec des composites carbone/époxy). Dissertation, ENSAM

Gaitonde VN, Karnik SR, Campos Rubio J et al (2008) Analysis of parametric influence on delamination in high-speed drilling of carbon fiber reinforced plastic composites. J Mater process tech 203:431–438

Biermann D, Feldhoff M (2012) Abrasive points for drill grinding of carbon fibre reinforced thermoset. CIRP Ann Manuf Technol 61:299–302

Tsao CC, Hocheng H (2005) Computerized tomography and C-scan for measuring delamination in the drilling of composite materials using various drills. Int J Mach Tool Manu 45:1282–1287

Turki Y, Habak M, Velasco R, Aboura Z, Khellil K, Vantomme P (2014) Experimental investigation of drilling damage and stitching effects on the mechanical behavior of carbon/epoxy composites. Int J Mach Tools Manuf 87:61–72

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Turki, Y., Habak, M., Velasco, R. et al. Highlighting cutting mechanisms encountered in carbon/epoxy composite drilling using orthogonal cutting. Int J Adv Manuf Technol 92, 685–697 (2017). https://doi.org/10.1007/s00170-017-0153-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0153-0