Abstract

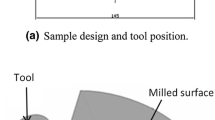

Machining process planning for milling hard materials with free-form surfaces using a ball nose end mill still requires empirical determination of the machining parameters, which can limit the efficiency of the process, reduce tool life, and adversely affect workpiece surface quality. Milling free-form surfaces differs from ordinary milling because the tool-surface contact changes constantly, causing the cutting speed to vary from the programmed value (in regions where the tool touches the surface with its nominal diameter and the tool axis is parallel to the surface) to zero (in regions where the center of the tool tip cuts the material and the tool axis is almost perpendicular to the surface at the point of contact). This paper focuses on this issue and investigates the influence of effective cutting speed and tool-surface contact on tool wear and surface roughness. High-speed milling experiments were carried out in which convex circular surfaces of hardened D6 steel were machined with a ball nose end mill keeping the effective tool diameter along the tool’s circular trajectory constant in each experiment. The input variables were the lead angle (and consequently the effective tool diameter, which was kept constant in each experiment but varied from one experiment to another) and feed direction (ascendant and descendant). As the effective tool diameter increased from one experiment to another, the feed rate decreased. The results show, in contrast to other findings in the literature, that contact between the center of the tool tip and the workpiece can increase tool life and reduce roughness when milling free-form surfaces in hardened steels. Furthermore, machining time is reduced as the smaller effective tool diameter leads to a higher feed rate. A relationship was also observed between the axial machining force and process stability when the tool tip is involved in the cutting process.

Similar content being viewed by others

References

Chiang S, Tsai C, Lee A (1995) Analysis of cutting forces in ball end milling. J Mater Process Technol Amst 47(3/4):231–249

Souza AF, Berkenbrock E, Diniz AE, Rodrigues AR (2014a) Influences of the tool path strategy on the machining force when milling free form geometries with a ball-end cutting tool. J Braz Soc Mech Sci Eng. doi:10.1007/s40430-014-0200-9

Bissacco G, Hansen HN, De Chiffre L (2006) Size effect on surface generation in micromilling of hardened tool steel. Ann CIRP 55:593–596

Ducobu F, Filippi E, Rivière LE (2009) Chip formation and minimum chip thickness in micro-milling. 12th CIRP Conference on modeling of machining operations. Donostia-San Sebastián, Spain

Ozturk E, Tunc LT, Budak, E (2009). Investigation of lead and tilt angle effects in 5-axis ball-end milling processes. International Journal of Machine Tools & Manufacture.

Souza AF, Machado A, Beckert SF, Diniz AE (2014b). Evaluating the roughness according to the tool path strategy when milling free form surfaces for mold application. Procedia CIRP. 6th CIRP International Conference on High Performance Cutting pp. 188–193

Becze CE, Clayton P, Chen L, El-Wardany TI, Elbestawi MA (2000) High-speed five-axis milling of hardened tool steel. International Journal of Machine Tools & Manufacture 40:869–885

Aspinwall DK, Dewes RC, Ng EG, Sage C, Soo SL (2007) The influence of cutter orientation and workpiece angle on machinability when high speed milling Inconel 718 under finishing conditions. Int J Mach Tools Manuf 47:1839–1846

Oliveira AJ, Diniz AE (2009). Tool life and tool wear in the semi-finish milling of inclined surfaces. Journal of Materials Processing Technology 5448–5455

Chen JSB, Huang YK, Chen MS (2005) Feedrate optimization and tool profile modification for the high-efficiency ball-end milling process. International Journal of Machine Tools & Manufacture 45:1070–1076

Boujelbene M, Moisan A, Torbaty S (2006). Study of the tool inclination in multi-axes milling. Bucareste, Romênia: Proceedings of the 15th International Conference on Manufacturing Systems—ICMaS

Souza AF, Diniz AE, Rodrigues AR, Coelho RT (2014c) Investigating the cutting phenomena in free-form milling using a ball-end cutting tool for die and mold manufacturing. Int J Adv Manuf Technol 71:1565–1577. doi:10.1007/s00170-013-5579-4

Scandiffio I, Diniz AE, Souza AF (2015) Evaluating surface roughness, tool life, and machining force when milling free-form shapes on hardened AISI D6 steel. Int J Adv Manuf Technol. doi:10.1007/s00170-015-7525-0

Bressan JD, Battiston GA, Gerbasi R, Daros DP, Gilapa LM (2006) Wear on tool steel AISI M2, D6 and 52100 coated with Al2O3 by the MOCVD process. J Mater Process Technol 179(2006):81–86

Castanhera IC, Diniz AE (2016) High speed milling of hardened steel convex surface. Procedia Manufacturing. 44th North American Manufacturing Research Conference, NAMRC 44, Blacksburg, Virginia, United States pp. 220–231. DOI: 10.1016/j.promfg.2016.08.020

Trent E, Wright PK (2000) Metal cutting. Butterworth-Heinemann, Boston

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Scandiffio, I., Diniz, A.E. & de Souza, A.F. The influence of tool-surface contact on tool life and surface roughness when milling free-form geometries in hardened steel. Int J Adv Manuf Technol 92, 615–626 (2017). https://doi.org/10.1007/s00170-017-0093-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0093-8