Abstract

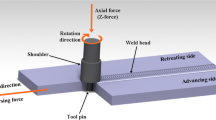

In FSW, insert materials are often used to both control the loading conditions as well as to trace the nature of materials flow. This current study aims at understanding the role played by inserts materials by using two different materials, copper and tin as inserts. The copper and tin have higher and lower melting points respectively as compared to aluminum. The metal strips are sandwiched between aluminum plates and friction stir welded at two different rotational speeds. The process loads and torque were recorded during the welding and compared with that obtained for normal butt-welding of aluminum sheets. In the case of copper insert, copper gets distributed in the matrix and it is possible to trace the flow of copper inside the aluminum. In the case of tin, it melts during the welding. The molten tin is squeezed out of faying surface and coats tool shoulder. This lowers the friction and which in turn lowers the torque (55%) and the consequent heat generation. The resultant reduction of temperature in the weld leads to higher tangential and normal loads. Compared to the case without insert, the normal loads for FSW processing with tin insert were higher by 2.2 times and tangential loads were higher by 5.5 times.

Similar content being viewed by others

References

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R Rep 50:1–78. doi:10.1016/j.mser.2005.07.001

Barnes T, Pashby I (2000) Joining techniques for aluminium spaceframes used in automobiles. J Mater Process Technol 99:62–71. doi:10.1016/S0924-0136(99)00367-2

Zhao H, White DR, DebRoy T (1999) Current issues and problems in laser welding of automotive aluminium alloys. Int Mater Rev 44:238–266. doi:10.1179/095066099101528298

Nadammal N, Kailas SV, Suwas S (2015) A bottom-up approach for optimization of friction stir processing parameters; a study on aluminium 2024-T3 alloy. Mater Des 65:127–138. doi:10.1016/j.matdes.2014.09.005

Thomas WM, Threadgill PL, Nicholas ED (1999) Feasibility of friction stir welding steel. Sci Technol Weld Join 4:365–372. doi:10.1179/136217199101538012

Murr LE, Li Y, Flores RD et al (1998) Intercalation vortices and related microstructural features in the friction-stir welding of dissimilar metals. Mater Res Innov 2:150–163. doi:10.1007/s100190050078

Al-Roubaiy AO, Nabat SM, Batako ADL (2014) Experimental and theoretical analysis of friction stir welding of Al–Cu joints. Int J Adv Manuf Technol 71:1631–1642. doi:10.1007/s00170-013-5563-z

Carlone P, Astarita A, Palazzo GS et al (2015) Microstructural aspects in Al–Cu dissimilar joining by FSW. Int J Adv Manuf Technol 79:1109–1116. doi:10.1007/s00170-015-6874-z

Chen YC, Nakata K (2009) Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Mater Des 30:469–474. doi:10.1016/j.matdes.2008.06.008

Dressler U, Biallas G, Alfaro Mercado U (2009) Friction stir welding of titanium alloy TiAl6V4 to aluminium alloy AA2024-T3. Mater Sci Eng A 526:113–117. doi:10.1016/j.msea.2009.07.006

Sheikh-Ahmad JY, Ozturk F, Jarrar F, Evis Z (2016) Thermal history and microstructure during friction stir welding of Al–Mg alloy. Int J Adv Manuf Technol. doi:10.1007/s00170-015-8239-z

Aonuma M, Nakata K (2012) Dissimilar metal joining of ZK60 magnesium alloy and titanium by friction stir welding. Mater Sci Eng B 177:543–548. doi:10.1016/j.mseb.2011.12.031

Uzun H, Dalle Donne C, Argagnotto A et al (2005) Friction stir welding of dissimilar Al 6013-T4 to X5CrNi18-10 stainless steel. Mater Des 26:41–46. doi:10.1016/j.matdes.2004.04.002

Schneider J, Radzilowski R (2014) Welding of very dissimilar materials (Fe-Al). JOM 66:2123–2129. doi:10.1007/s11837-014-1134-5

Kumar N, Yuan W, Mishra RS (2015) Friction stir welding of dissimilar alloys and materials. Butterworth-Heinemann, UK

Robson JD, Cui S, Chen ZW (2010) Incipient melting during friction stir processing of AZ91 magnesium castings. Mater Sci Eng A 527:7299–7304. doi:10.1016/j.msea.2010.07.093

Yan J, Sutton MA, Reynolds AP (2005) Process–structure–property relationships for nugget and heat affected zone regions of AA2524–T351 friction stir welds. Sci Technol Weld Join 10:725–736. doi:10.1179/174329305X68778

Long T, Tang W, Reynolds AP (2007) Process response parameter relationships in aluminium alloy friction stir welds. Sci Technol Weld Join 12:311–317. doi:10.1179/174329307X197566

Inada K, Fujii H, Ji YS et al (2010) Effect of gap on FSW joint formation and development of friction powder processing. Sci Technol Weld Join 15:131–136. doi:10.1179/136217109X12568132624244

Chang W-S, Rajesh SR, Chun C-K, Kim H-J (2011) Microstructure and mechanical properties of hybrid laser-friction stir welding between AA6061-T6 Al alloy and AZ31 Mg alloy. J Mater Sci Technol 27:199–204. doi:10.1016/S1005-0302(11)60049-2

Shiri SG, Sarani A, Hosseini SRE, Roudini G (2013) Diffusion in FSW joints by inserting the metallic foils. J Mater Sci Technol 29:1091–1095. doi:10.1016/j.jmst.2013.07.003

Lee R-T, Liu C-T, Chiou Y-C, Chen H-L (2013) Effect of nickel coating on the shear strength of FSW lap joint between Ni–Cu alloy and steel. J Mater Process Technol 213:69–74. doi:10.1016/j.jmatprotec.2012.07.014

Seidel TU, Reynolds AP (2001) Visualization of the material flow in AA2195 friction-stir welds using a marker insert technique. Metall Mater Trans A 32:2879–2884. doi:10.1007/s11661-001-1038-1

Schmidt HNB, Dickerson TL, Hattel JH (2006) Material flow in butt friction stir welds in AA2024-T3. Acta Mater 54:1199–1209. doi:10.1016/j.actamat.2005.10.052

Colligan K (1999) Material flow behavior during friction welding of aluminum. Weld J 75:229s–237s

Kang SH, Han HN, Oh KH et al (2009) Investigation of the material flow and texture evolution in friction-stir welded aluminum alloy. Met Mater Int 15:1027–1031. doi:10.1007/s12540-009-1027-2

Doude HR, Schneider JA, Nunes AC (2014) Influence of the tool shoulder contact conditions on the material flow during friction stir welding. Metall Mater Trans A 45:4411–4422. doi:10.1007/s11661-014-2384-0

J.A. Schneider, A.C. Nunes, Jr (2006) Influence of processing parameters on the flow path in friction stir welding. ntrs.nasa.gov

Schneider J, Beshears R, Nunes AC (2006) Interfacial sticking and slipping in the friction stir welding process. Mater Sci Eng A 435-436:297–304. doi:10.1016/j.msea.2006.07.082

Shinoda T, Kondo Y (1997) Friction stir welding of aluminium plate. Weld Int 11:179–184. doi:10.1080/09507119709451948

Hwang Y-M, Kang Z-W, Chiou Y-C, Hsu H-H (2008) Experimental study on temperature distributions within the workpiece during friction stir welding of aluminum alloys. Int J Mach Tools Manuf 48:778–787. doi:10.1016/j.ijmachtools.2007.12.003

Tang W, Guo X, McCLURE JC et al (1998) Heat input and temperature distribution in friction stir welding. J Mater Process Manuf Sci 7:163–172. doi:10.1106/55TF-PF2G-JBH2-1Q2B

Mishra RS, Mahoney MW (2007) Friction stir welding and processing. ASM International, Materials Park, Ohio

Chao YJ, Qi X, Tang W (2003) Heat transfer in friction stir welding—experimental and numerical studies. J Manuf Sci Eng 125:138. doi:10.1115/1.1537741

Zimmer S, Langlois L, Laye J, Bigot R (2010) Experimental investigation of the influence of the FSW plunge processing parameters on the maximum generated force and torque. Int J Adv Manuf Technol 47:201–215. doi:10.1007/s00170-009-2188-3

Atharifar H, Lin D, Kovacevic R (2009) Numerical and experimental investigations on the loads carried by the tool during friction stir welding. J Mater Eng Perform 18:339–350. doi:10.1007/s11665-008-9298-1

Su H, Wu CS, Pittner A, Rethmeier M (2013) Simultaneous measurement of tool torque, traverse force and axial force in friction stir welding. J Manuf Process 15:495–500. doi:10.1016/j.jmapro.2013.09.001

Frigaard Ø, Grong Ø, Midling OT (2001) A process model for friction stir welding of age hardening aluminum alloys. Metall Mater Trans A 32:1189–1200. doi:10.1007/s11661-001-0128-4

Heurtier P, Jones MJ, Desrayaud C et al (2006) Mechanical and thermal modelling of friction stir welding. J Mater Process Technol 171:348–357. doi:10.1016/j.jmatprotec.2005.07.014

Sutton M, Yang B, Reynolds A, Taylor R (2002) Microstructural studies of friction stir welds in 2024-T3 aluminum. Mater Sci Eng A 323:160–166. doi:10.1016/S0921-5093(01)01358-2

Schneider JA, Nunes AC (2004) Characterization of plastic flow and resulting microtextures in a friction stir weld. Metall Mater Trans B Process Metall Mater Process Sci 35:777–783. doi:10.1007/s11663-004-0018-4

Arora A, Nandan R, Reynolds AP, DebRoy T (2009) Torque, power requirement and stir zone geometry in friction stir welding through modeling and experiments. Scr Mater 60:13–16. doi:10.1016/j.scriptamat.2008.08.015

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dixit, S., C., M.H., Kailas, S.V. et al. Role of insert material on process loads during FSW. Int J Adv Manuf Technol 91, 3427–3435 (2017). https://doi.org/10.1007/s00170-016-9974-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9974-5